Pneumatic level measurement

With the pneumatic level measurement (bubbling method), compressed air is bubbled into the liquid medium through a thin hose or tube; the resulting overpressure is measured and corresponds to the liquid column . It is a simple and inexpensive method for hydrostatic level measurement. The pressure difference is independent of, for example, foam, turbulence and boiler internals.

With a defined level, the pressure can also be used to measure the density or the height of the separating layer.

Measuring principle

Air is introduced through a tube immersed in a medium. The lower end is at the bottom of the measuring location (container, channel) or has a fixed distance to it. When small bubbles emerge from the tube and rise to the surface, it is completely filled with air. The pressure of the air supplied is identical to the counter pressure of the water column in the tube.

Thus, the back pressure is a measure of the pressure at the bottom of the pipe, which is generated by the level of the medium. This hydrostatic pressure in relation to the air pressure is evaluated by a differential pressure regulator. The hydrostatic pressure can be calculated according to Pascal's law :

With:

- p ( h ) - hydrostatic pressure as a function of water height; [ p ] = Pa

- g - spatial factor (acceleration due to gravity); [ g ] = m / s²

- - Density (Rho) (for water: = 1,000 kg / m³); [ ] = kg / m³

- h - height of the column of liquid; [ h ] = m, cm or mm

Level measurement

One-pipe principle for open containers: The counter pressure is applied to the input side of the transmitter, a so-called differential pressure regulator, while the low-pressure side is open to the earth's atmosphere . The measured differential pressure is therefore a measure of the liquid level.

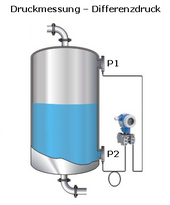

If the container to be measured is under pressure , the difference between the pressures on the surface of the liquid and on the bottom of the container must be measured, see figure on the right .

Further measurements

Flow measurement

By measuring the level on a channel of a defined width, the flow can be measured indirectly.

As with the level, the flow rate is measured with a pipe, the measured differential pressure is fed with the characteristic data of the measuring point to a real-time flow computer which processes these values and outputs them as the corresponding flow rates. See example: Venturi flow measurement .

Measurement of density and interface

Two-pipe principle: If the level of the medium is constant, such as with a continuous overflow, a change in the density of the medium or the separating layer results in a change in the differential pressure. This means that the density or, if the density is known, the size of the separating layer can also be measured with the bubbling method. If the tank level fluctuates, these measurements are made with two pipes of different lengths attached to opposite sides of the transmitter. The separating layer here denotes the sludge level or the limit level between two phases .

Applications

- Sewage treatment plants

- Industry

- Level measurement

- Density determination

- Interface measurement

- Water management

- open channels

- Water levels

advantages

- Inexpensive

- can be used for level measurement, flow measurement, density and interface measurement

disadvantage

Cannot be used when

- the process medium could crystallize in the transmission lines.

- if there is a risk of frost because the compressed air line could freeze due to condensate.

- the process medium is aggressive and must not come into direct contact with the transmitter.

- requires high maintenance, cleaning the immersion tubes, etc.

Individual evidence

- ^ Walter Fendt: Gravity pressure in liquids. February 3, 1999 .

swell

- DIN 19559 parts 1 and 2: Flow measurement of waste water in open channels and gravity lines .

literature

- Rüdiger Settelmeyer: Process automation - from field device to automation solution. Christiani, Konstanz 2007, ISBN 978-3-86522-305-0 .

- Ellen Amberger: Level measurement technology. Basics and application examples (= The Library of Technology, Volume 14). Verl. Moderne Industrie, Landsberg / Lech 1988, ISBN 3-478-93014-6 .