Polarimeter

A polarimeter is a device of the polarimetry to measure the rotation of the polarization plane of linearly polarized light through optically active substances. The measured optical angle of rotation α depends on the intrinsic property of the substance under investigation and its concentration. Polarimeters are often used for the quantitative determination of the concentration of optically active substances in solutions, for example for determining the sugar content of an aqueous solution ( saccharimetry ).

principle

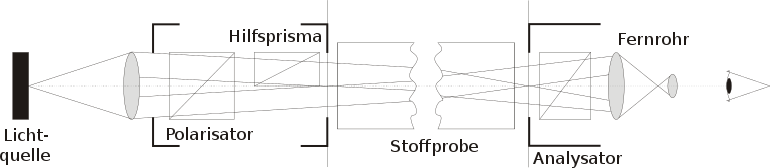

A polarimeter is usually made up of two Nicol prisms . The fixed polarizer linearly polarizes the light from the light source. The rotatable analyzer behind it is used to determine the position of the polarization plane.

If you cross the two polarization filters, no light can pass; the field of view that the observer looks at remains dark. If the sample substance is brought between the two polarization filters, depending on the rotation value, it becomes brighter, which enables the rotation value to be measured.

A commonly used instrument is the half-shadow by F. Lippich . In this case, part of the light that falls into A is slightly rotated beforehand by an auxiliary prism H (1 ° to 10 °). This means that you can see two "fields".

Polarizer P and analyzer A are Nicol prisms, where P is fixed and A is rotatable. When A and P are parallel, the image is bright; an A rotated by 90 ° darkens the image. If A and P are crossed, one half is dark while the other half is light. If you now turn A through 360 °, areas of high and low total brightness appear alternately (4 in total). The arrangement described (Figure 1 and 2) is just one of many ways to set up a polarimeter. In other arrangements, the polarizer P is rotated while the analyzer A is stationary, and both parts can also be rotated simultaneously. Instead of a slow rotation, a polarizing element can also rotate quickly; with a detector instead of the eye, a sinusoidal variation in brightness can then be registered. The rotation value is then determined from the phase shift compared to the signal curve without a sample.

Automatic polarimeter

The correct measurement of the rotation value with a manual polarimeter is time-consuming and requires experience. Automatic, electronically controlled polarimeters are used particularly in the industrial sector and in laboratories with a large number of measurements. Their short measurement time of up to one second per measurement and a computer interface allow series of measurements.

Specification of the measured value

Since many factors (layer thickness of the sample, solvent , temperature, wavelength of the light, etc.) influence the rotation value, the rotation value based on the concentration and the irradiated sample thickness is given as a specific rotation angle or specific rotation when comparing different samples / substances . This is often also given in degrees or dimensionless, in this case the specific angle of rotation is normalized to 10 cm layer thickness, 100 ml of solvent and 1 g of optically active substance.

The rotation value α and thus the specific rotation angle depend on the frequency of the light, the temperature, the solvent used and, if applicable, the concentration, so these decisive parameters are also specified. Measurements are usually made at 589 nm ( sodium D line ), but also at other wavelengths. Due to the temperature dependency of the rotation value, measurements are usually thermostated at 20 ° C, 22 ° C or 25 ° C; other information can also be found in the literature. To specify the rotation value α of a chiral substance, the measurement conditions are given.

Examples:

- → Positive sign, 25 ° C measuring temperature, yellow sodium light (sodium D line), concentration 2 g of substance dissolved in 100 ml in water.

- → negative sign, 20 ° C measuring temperature, 589 nm wavelength , concentration 4 g substance dissolved in 100 ml in chloroform .

Interference filter in polarimeters

With the help of interference filters it is possible to set the exact wavelength of circular polarimeters. The manufacturing accuracy of the filters used here is ± 2 nm. Therefore, it is common in polarimetry to make use of the angle dependence of these filters. For example, filters with a somewhat longer central wavelength are used and the target wavelength can be set by carefully tilting the filter mechanically. This is continuously checked with the help of certified quartz plates with known optical rotation during the setting. This type of wavelength adjustment usually works reliably - this becomes more complicated if the central wavelength should continue to be accurate to 0.01 nm over days or months under changing environmental conditions. Since temperature and aging effects affect the wavelength, constant checking and readjustment is necessary.

Using the example of a 26% sugar solution, a change in wavelength of 0.03 nm leads to a 0.0035 ° change in rotation at a wavelength of 589 nm. This error is increased if the same wavelength error occurs at 405 nm. Here the error is already 0.013 ° and thus exceeds the required tolerance . A substance with a very high rotation value leads to correspondingly higher errors, such as with D - (-) - limonene . Under controlled laboratory conditions - 20 ° C or at least constant room temperature - polarimeters with the mentioned tilting technique work relatively satisfactorily. In order to ensure a stable wavelength, there is another possibility, which, particularly for the sugar industry, makes use of the great similarity between the optical rotation of the quartz crystal and aqueous sugar solutions: the so-called quartz wedge compensation.

Quartz wedge polarimeter

The fact that the optical rotation dispersion (ORD) of quartz is almost identical to that of a sucrose solution is used to produce a sugar polarimeter with very high precision. The quartz wedge compensation principle is patent-protected and has established itself in the sugar industry to this day due to its high level of reliability. This polarimeter uses a quartz wedge that is shifted in the optical beam path. The polarizer and analyzer are fixed at 90 ° to each other. The device measures the distance of the quartz wedge, which compensates for the rotation of the sample. Instead of the angular encoder of a circular polarimeter, a linear encoder is used here.

This is a proprietary principle of Schmidt + Haensch , which is used exclusively. Since the quartz and the sample react in the same way with small shifts in the wavelength , these changes are compensated so that the effect is negligible. The resulting advantages are therefore:

- Little influence on wavelength shifts

- Long-term stability of the measured values without calibration

Such a device thus represents a highly stable system for use in the sugar industry, since it is not subject to any temperature influence, no aging and no need for adjustment.

Checking polarimeters with quartz plates

Quartz , also known as deep quartz or α-quartz, is a mineral with the chemical composition SiO 2 and trigonal symmetry . The crystallization of the quartz in an enantiomorphic structure rotates the oscillation plane of the light that traverses a deep quartz in the direction of the c-axis.

The chemical stability of quartz is extremely high, it is insoluble in water and can only be attacked by hydrofluoric acid and soda melt. The optical transmission ranges from 160 nm to 3000 nm. The optical activity (rotation of the polarization plane of the light) depends on the wavelength , temperature and thickness of the quartz. These properties make quartz an ideal material for checking polarimeters.

PTB quartz plates

These quartz control plates have defined rotation values depending on their thickness and temperature as well as the wavelength of the light used. Any rotation value can be generated by adjusting the thickness and can be determined with a precision polarimeter and documented with a calibration certificate. The Physikalisch-Technische Bundesanstalt (PTB) based in Braunschweig is the only recognized state body equipped for this initial certification of quartz crystals.

Calibration at PTB is based on the recommendations of the ICUMSA ( International Commission for Uniform Methods of Sugar Analysis ) or OIML ( International Organization for Legal Metrology ). A calibration there consists of a preliminary test in which the basic calibration capability is checked - the quartz control plates must meet the minimum requirements with regard to their dimensions, optical purity , flatness , plane parallelism and axis errors . The actual measured value, the optical rotation, is then determined with the precision polarimeter available at PTB. The measurement uncertainty achieved here is 0.001 °.

Testing using quartz plates

However, quartz also has optical defects. In addition to the formation of twins , dislocation lines , inclusions, these can also be axis errors and inhomogeneities . Such errors have a negative effect on the measurement in the polarimetric application. Since the diameter of the measuring beam in a modern polarimeter varies between 1 mm and 6 mm, and its intensity profile can also change within the sample space, the measured values for a quartz with optical errors can vary depending on the position in the sample space and rotation around its own axis expected. Therefore, when checking a polarimeter using a quartz plate, several measurements should always be carried out in different positions.

literature

- Reinhard Matissek, Gabriele Steiner, Markus Fischer: Food analysis. 3rd ed., Springer, Berlin / Heidelberg 2006, pp. 117, 145-147, 352-356.

Footnotes

- ↑ International Union of Pure and Applied Chemistry ( IUPAC ): Quantities, units and symbols in physical chemistry , Blackwell Science, Oxford, 1993. ISBN 0-632-03583-8 , p. 33 ( PDF ).

- ↑ a b c PTB Braunschweig: "Polarimetric calibration of quartz control plates" , 2010.

![\ left [\ alpha \ right]](https://wikimedia.org/api/rest_v1/media/math/render/svg/77355464a2862c6c6f7b451038d16959999142ff)

![\ left [\ alpha \ right] _ {{\ text {D}}} ^ {{25}} = + 28 {\ mathrm {\ (c = 2; \ H_ {2} O)}}](https://wikimedia.org/api/rest_v1/media/math/render/svg/cd91693293b33c5e6d26651bfbfdd1512e63c867)

![\ left [\ alpha \ right] _ {{589}} ^ {{20}} = - 147 {\ mathrm {\ (c = 4; \ CHCl_ {3})}}](https://wikimedia.org/api/rest_v1/media/math/render/svg/49738182ba6bbfdc6f98e2d74792bcd4a0969faf)