Shock protection

In mechanical wristwatches , jewelry and pocket watches, shock protection is an elastically secured bearing , which serves to absorb impacts against the journal of the balance shaft .

The balance wheel is mounted in two bearings (consisting of perforated and cap jewels) arranged in the plate and in the balance cock (or the balance bridge). The delicate bearing journals of the balance are prone to breakage when impacted (see balance ). They have a very small diameter. The trumpet-like cone shape counteracts the risk of breakage, but does not completely eliminate it. This is only guaranteed by shock protection.

The various designs of shock protection devices all allow cleaning and (re) oiling of the shock protection device if necessary.

The first variant of a shock protection was invented by Abraham Louis Breguet and named Pare-chute (also Parachute ). Further developments in the 1930s were the Wyler system (balance wheel with springy legs) and from the 1950s onwards, among other things, the Parechoc and KIF Flector shock protection from Parechoc SA , the Etachoc from ETA , the Diashock from Seiko , the Parashock from Citizen , the Shock-Resist shock protection, which was already described as a great advance in watch technology in 1938, and the Super-Shock-Resist shock protection, which came onto the market in 1933, as well as the Incabloc shock protection, which is mostly used today, fixed with a (lyre-shaped) spring clip. In 1966 Parachoc SA offered the shock protection system KIF Reflector together with the regulation system as "Spirotor".

Incabloc Shock Protection System , Incabloc for short , is the trade name of a mount for the bearing and cap stones of the balance with a lyre- shaped spring . After extensive preparatory work, it was founded in 1933 by Charles Ochsner, Georges Braunschweig and Fritz Marti in the company Universal Escapements Ltd. ( Porte-Echappement Universal ) in La Chaux-de-Fonds and used for the first time from 1934 in the watches of the Société des Montres West End SA . Improved in 1938, the system could be installed in all calibres. Anchor works have been fitted with shock protection since around 1960. It is still produced and sold by Incabloc SA , among others .

A curved and thus elastic bridge of the balance wheel ( Incaflex ) can be used as additional shock protection .

The simpler and inexpensive pin lever watches were also given shock protection with Antichoc , a self-lubricating diaphragm bearing .

details

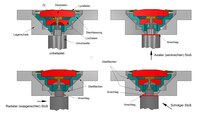

The basic principle of almost all (diverse) shock protection devices is that when the balance is hit, the bearing journals move the jewels against a spring force until a stop surface of the (under the given conditions) unbreakable balance shaft hits a boundary surface that absorbs the shock. The pins are then relieved. The spring force is measured in such a way that on the one hand the breaking limit of the pin is by far not reached during this movement and on the other hand the weight of the balance is safely supported in every position of the balance shaft. After the impact, the balance and jewels return to their original position due to the spring force. The most widely used shock protection is that of the Incabloc company. It should be noted that shocks always occur on the watch case and only have an indirect effect on it due to the inertia of the balance. The speed of the watch is only marginally influenced by the shock compensation.

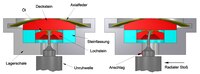

The Incabloc shock protection consists of a bearing shell that is fastened (pressed, clamped, screwed) in the plate or in the balance cock (or the balance bridge). The bearing shell has tapered sliding surfaces (inner cone) and boundary surfaces. The stone setting is inserted into the bearing shell. It is also provided with conical sliding surfaces (outer cone). The perforated stone is firmly pressed into the stone setting. The capstone lies loosely in the stone setting with its flat surface facing the perforated stone. A leaf spring is used as the spring, which is known as a lyre spring because of its shape similar to the ancient Greek plucked instrument. It can be inserted and hooked into T-shaped recesses in the bearing shell.

The shock protection can be removed. This has the advantage that it can be cleaned and re-oiled if necessary. The following assembly is shown in the picture. A drop of oil is placed on the flat surface of the capstone . Due to the surface tension ( cohesion ) the oil takes on a dome shape. The stone is turned over and placed in the stone lining. The shape of the perforated stone ensures through capillary action (ring wedge between the perforated and capping stone) that the oil remains in the space between the perforated and capping stone near the stone hole. After inserting the balance, it pulls itself up a little on the pivot. The capstone used with the stone bearing arches the lyre spring hooked in the last assembly step and thus pretensions it.

A portable watch and thus the balance wheel can be in any position. The picture shows the conditions for the upper shock protection with the balance shaft in a vertical position. Other (shock-free) positions differ from the vertical, unloaded position only in that the pegs are constantly in contact with the respective perforated stone due to the gravitation acting on the balance wheel (without moving it, since, as mentioned above, the spring force is measured accordingly).

In the event of a vertical (upward) impact, the pin moves the capstone upwards until the stop surface (collar) of the balance shaft meets the boundary surface of the bearing shell (lower flat surface) and absorbs the impact. The adhesion mediated by the oil means that the stone setting (on which the pin does not exert any force in this case) is also moved upwards. Due to the force exerted by the pin on the perforated stone, a radial (horizontal) impact leads to the displacement of the stone setting on the inner cone of the bearing shell at an angle upwards until the cylindrical stop surface of the balance shaft rests against the inner cylindrical boundary surface of the bearing shell. The stone setting is not tilted, but its axis only shifts parallel to the unloaded starting position (thus also that of the stones). In the case of an oblique shock, there is a combination of axial and radial shock, so that both stop surfaces of the balance shaft become effective. Except in the case of an axial shock, which is an idealization anyway, the shock protection of both balance bearings are always effective. For example, in the event of a radial impact, the upper stone setting moves diagonally upwards and the lower one diagonally downwards. After a bump, the balance wheel returns to its unloaded starting position due to the spring force of the lyre springs.

The Super Shock Resist shock protection uses two leaf springs. One enables the cap stone to move axially (axial spring), while the other ensures an all-round radial displacement of the perforated stone (radial spring). A special form of radial spring is required for this. The capstone sits firmly in the capstone frame. The perforated stone is held in place by the radial spring. During assembly, the axial spring is inserted with its tabs into the grooves of the bearing shell, the tabs are pressed down and then the spring is twisted so that the tabs sit under the edge of the bearing shell with tension. The spring is thus arched by the capstone frame and placed under tension. In the event of a radial impact, the perforated stone slides on a flat surface of the bearing shell against the force of the radial spring. An axial impact moves the capstone with its socket axially in the bearing shell. The stop and boundary surfaces correspond to those of the Incabloc safety device.

The Junghans company has developed a shock protection system that is similar to the Super Shock Resist protection system. However, no radial springs are used. Instead, the balance pins are made very long and are themselves springs. In the event of radial impact, they bend elastically until the stop surface of the balance shaft strikes the boundary surface of the bearing shell. After the impact, they spring back to their original shape. In the picture, the deformation is exaggerated for clarity.

The Incaflex system is not really a shock protection. The elastically deformable balance arm legs (similar to the radial spring of the Super Shock Resist fuse) only ensure that a shock does not act suddenly on the balance pin, but rather that the force is transmitted in a swelling manner.

literature

- Otto Böckle, Wilhelm Brauns: Textbook for the watchmaking trade. Work skills and materials. 8-10 Edition. Wilhelm Knapp, Halle (Saale) 1951 (reprint, edited by Michael Stern. Heel, Königswinter 2010, ISBN 978-3-86852-288-4 ).

- H. Kühnhanns: Self- winding shock protection. In: The clock. Issue 23, 1954, pp. 12-14.

- F. Marti: Has there been any development in shock protection technology? In: Journal Suisse d'Horlogerie et de Bijouterie. 1954, pp. 420-422.

- Helmut Kahlert , Richard Mühe , Gisbert L. Brunner : Wristwatches: 100 years of development history. Callwey, Munich 1983; 5th edition, ibid. 1996, ISBN 3-7667-1241-1 , pp. 43-46 and 506.

- Hermann Brinkmann: Introduction to watchmaking. (= The watchmaking school. Volume 2). 10th, unchanged edition. Wilhelm Knapp, Düsseldorf 2005, ISBN 3-87420-010-8 .

- George Daniels : Watchmaking. Updated 2011 edition. Philip Wilson Publishers, London 2011, ISBN 978-0-85667-704-5 .

Web links

- Volker Vyskocil: Incabloc ( Flash ; 7 kB), Super-Shock-Resist ( Flash ; 13 kB) animation

- Clockswatches.com: Incabloc

Individual evidence

Attention! With DEPATISnet information, an error message often appears the first time it is clicked. The second time the link works.

- ↑ Georges-Albert Berner: Illustrated specialist dictionary of watchmaking. Keyword shock absorbers. Retrieved January 25, 2012.

- ↑ The full backup KIF. 2 booklets. Parechoc SA, Le Sentier 1962.

- ^ Helmut Kahlert, Richard Mühe, Gisbert L. Brunner: Wristwatches: 100 years of development history. 1996, p. 44.

- ^ Advertisement for the Incabloc shock protection from 1953 . Retrieved February 5, 2012.

- ↑ DEPATISnet | Document CH000000168494A. (PDF) Retrieved October 11, 2017 .

- ^ Helmut Kahlert, Richard Mühe, Gisbert L. Brunner: Wristwatches: 100 years of development history. 1996, p. 46.

- ↑ Shock and Waterproof. In: Mechanical Magic in Three Dimensions. Montres Passion magazine , 2010, accessed February 5, 2012 .

- ^ Incabloc, SA. Retrieved December 1, 2017.

- ^ Helmut Kahlert, Richard Mühe, Gisbert L. Brunner: Wristwatches: 100 years of development history. 1996, p. 46.

- ^ Zdenek Martinek, Jaroslav Rehor: Mechanical watches . VEB Verlag Technik Berlin, ISBN 3-341-00022-4 .

- ↑ DEPATISnet | Document DE000000842429B. (PDF) Retrieved October 11, 2017 .