Stone (clock)

In watchmaking, stone (English jewel , French pierre or rubis ) refers to a bearing made of precious stones . These jewels are z. B. perforated stones, cap stones, rolling bearing stones, pallet stones and the ellipse in clockworks .

properties

Due to their perforation, bearing stones (synonymous with perforated stones ), together with the metal pins of the gear train shafts, the balance shaft and the armature shaft, form slide bearings for watches. Compared to metal, there is less friction and less wear . Bearing stones were developed in 1704 by the Swiss mathematician Nicolas Fatio de Duillier .

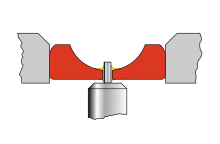

The bearings used to be made from natural gemstones , whereas today they are made from synthetic ruby or other corundum . They are pressed into the work plate ( gray in the picture) or screwed into a gold frame (French chaton ) and adjusted. The hemispherical depression in a perforated stone (without cover) is called an oil depression , which is used to absorb the watch oil ( yellow in the picture).

Bricks from rolling bearings (e.g. in the ball bearing of the rotor of an automatic watch ) are spherical or roller-shaped. These rolling bearing stones and the cap stones are not perforated and are not referred to as bearing stones.

Furthermore, stones on the escapement (anchor pallet stones , lever stone ) are used as slide bearings . These were first used by Thomas Mudge , who invented the lever escapement around 1757.

Number of stones

A high quality mechanical wristwatch with manual winding requires at least 15 functional stones:

- ten perforated stones (two each for the pivot of the balance wheel, anchor, escape wheel, fourth wheel and third wheel)

- two cap stones for the balance

- two pallet stones for the anchor

- a lever stone (ellipse)

In addition, there can be two cylindrical roller bearings for the barrel , two perforated stones for the minute wheel and two cap stones each for the anchor and escape wheel. The more complex a movement is built ( Grande Complication ), the more jewels are generally necessary, e.g. B. with automatic winding (+ at least 4 stones for the ball bearing of the rotor), perpetual calendar , chronograph or repeater hammer mechanism increases the number of stones required. However, the number of stones says nothing about the quality of the movement (see finissage ), but rather should serve the own reputation or to stand out from competitors. Manufacturers of luxury watches such as A. Lange & Söhne process between 30 and 70 jewels. As a sales argument, special dials are designed, which are intended to give an indication of the number of stones used.

In the course of industrialization in Europe, the demand for high quality and handcrafted watches increased. With numerous innovations in storage technology, the demand for rubies also increased. With the discovery of various artificial processes ( Verneuil process ), it was increasingly possible to fall back on synthetic rubies ( corundum ) with the same material requirements such as strength or processing options.

literature

- Otto Böckle, Wilhelm Brauns: Textbook for the watchmaking trade. Work skills and materials. 8-10 Edition. Wilhelm Knapp, Halle (Saale) 1951 (reprint, edited by Michael Stern. Heel, Königswinter 2010, ISBN 978-3-86852-288-4 ).

- Hermann Brinkmann: Introduction to watchmaking (= The watchmaking school. Vol. 2). 10th unchanged edition. Wilhelm Knapp, Düsseldorf 2005, ISBN 3-87420-010-8 .

- George Daniels : Watchmaking. Updated 2011 edition. Philip Wilson Publishers, London 2011, ISBN 978-0-85667-704-5 .

Web links

Individual evidence

- ^ Helmut Kahlert , Richard Mühe , Gisbert L. Brunner , Christian Pfeiffer-Belli: wrist watches: 100 years of development history. Callwey, Munich 1983; 5th edition, ibid 1996, ISBN 3-7667-1241-1 , p. 505.

- ↑ Georges-Albert Berner: Illustrated specialist dictionary of watchmaking. Keyword Fatio (Nicholas). (electronic version). Retrieved February 17, 2012.

- ↑ Georges-Albert Berner: Illustrated specialist dictionary of watchmaking. Keyword stone. (electronic version). Retrieved January 26, 2012.

- ↑ Georges-Albert Berner: Illustrated specialist dictionary of watchmaking. Keyword Mudge (Thomas). (electronic version). Retrieved February 17, 2012.

- ↑ Willis I. Milham: Time and Time Keepers . Omnigraphics, Detroit MI 1945, ISBN 978-0780800083 , pp. 114-116.

- ↑ Ed Hahn: What does 17 jewels mean? . In: Sec. 1.1.3 Mechanical Watch FAQ v.1.0 . TimeZone.com. Archived from the original on July 1, 2008. Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice. Retrieved February 4, 2012.

- ↑ Men's watches: stones / bearing stones / rubies (electronic version). Retrieved June 29, 2016.

- ↑ Author: Bernhard Neumann Textbook of Chemical Technology and Metallurgy: I Fuels Inorganic Industries Springer-Verlag, March 8, 2013, ISBN 978-3-642-92056-1 , 586 pages