Suspension polymerization

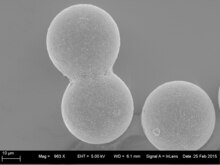

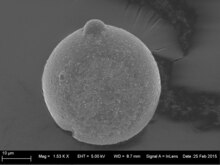

Suspension polymerization is a method of polymerization in which a water-insoluble monomer is dispersed in water . An initiator is used which is preferably soluble in the monomer. The reaction then takes place in the monomer droplets and a suspension of the polymer is formed . The product usually obtained is “pearls”, which is why the word pearl polymerisation is also used.

Mostly it is a radical polymerization from which polymer particles with a relatively broad particle size distribution emerge.

IUPAC definition

The IUPAC defines the suspension polymerization as a polymerization in which a polymer is formed within monomer or monomer-solvent droplets, they are in a continuous phase which is a non-solvent for both the monomer, as well as for the resulting polymer. In suspension polymerization, the initiator is mainly in the monomer phase. In the case of suspension polymerization, the monomer or monomer solvent droplets generally have a diameter of more than 10 μm.

principle

First, the monomer is dispersed in water, or some other liquid phase, which is a nonsolvent for both the monomer and the resulting polymer. In principle, at this point in time it is an emulsion that later changes into a suspension. Furthermore, initiator (mostly already pre-dissolved in the monomer) and protective colloids are added. The latter are intended to prevent the resulting monomer droplets from flowing together and the emulsion from separating. For example, polyvinyl alcohol , methyl cellulose , gelatin , polyacrylic acid , tricalcium phosphate are used for this purpose . If the protective colloid fails, the entire reaction may fail with a dangerous outcome due to the complete hardening of the reactor with the occurrence of the Trommsdorff effect or partially fused polymer particles, which then have undesirable properties.

The temperature is then brought to the reaction level at which the initiator triggers the polymerization. Finally, the polymer spheres (diameter from 20 µm to a few millimeters) are cut off and processed.

The monomers used must have a high degree of purity, since the polymer can then only be cleaned to a limited extent (externally). Also copolymerizations can be carried out with this method.

use

Suspension polymerization is widely used in the production of various commercial polymers, such as. B. polymethyl methacrylate , polyvinyl chloride , polystyrene or styrene-acrylonitrile copolymers .

See also

Individual evidence

- ↑ Entry on suspension polymerization. In: Römpp Online . Georg Thieme Verlag, accessed on April 13, 2014.

- ↑ Stanislaw Slomkowski, José V. Alemán, Robert G. Gilbert, Michael Hess, Kazuyuki Horie: Terminology of polymers and polymerization processes in dispersed systems (IUPAC Recommendations 2011) . In: Pure and Applied Chemistry . tape 83 , no. 12 , September 10, 2011, ISSN 1365-3075 , p. 2245 , doi : 10.1351 / pac-rec-10-06-03 ( degruyter.com [accessed on April 5, 2018]).

- ↑ Eduardo Vivaldo-Lima, Philip E. Wood, Archie E. Hamielec, Alexander Penlidis: An Updated Review on Suspension Polymerization . In: Industrial & Engineering Chemistry Research . tape 36 , no. 4 , April 1, 1997, ISSN 0888-5885 , p. 939-965 , doi : 10.1021 / ie960361g .