Vacuum capacitor

A vacuum capacitor is an electrical capacitor in which a high vacuum with a gas pressure of around 10 −7 Torr or 1.33 · 10 −7 mbar is used as the dielectric .

General

Vacuum capacitors are required as resonant circuit capacitors in high-frequency transmitters , as well as in applications where high voltages occur, e.g. B. in power LC resonant circuits for radio and television transmitters and in HF amplifier systems, in magnetrons for pulse shaping in the output circuit , in high-frequency welding devices and high-frequency drying systems, in plasma coating and plasma etching systems in the semiconductor industry and in nuclear magnetic resonance devices (MRI) as non-magnetizable capacitors.

These applications require a very high dielectric strength and an extremely high current carrying capacity of the capacitors. Vacuum capacitors with dielectric strengths of up to 90 kV and current capacities of up to 1000 A are manufactured.

The low gas pressure of the vacuum reduces the probability of impact ionization of the air molecules ( avalanche effect ) squarely with the falling air pressure. This relationship is described in Paschen's law . In addition, the low air pressure of the high vacuum reduces the occurrence of spark discharges due to peak action on mechanical irregularities in the electrodes . This results in the very high dielectric strength of capacitors with a vacuum dielectric. Depending on the gas pressure, it lies between 20 and 500 kV / mm, is given on average at around 40 kV / mm and is therefore around ten times higher than for capacitors with an air dielectric at normal air pressure.

The main advantages of vacuum capacitors compared to ceramic capacitors (high frequency capacitors) and air capacitors with the same performance specification are:

- smaller dimensions,

- significantly lower ohmic losses (better quality factor Q )

- higher current carrying capacity,

- self-healing (no insulating material available that can be damaged by a sparkover).

Vacuum capacitors are manufactured in two designs, as fixed capacitors with a constant capacitance value and as variable vacuum capacitors , the respective capacitance of which is mechanically steplessly adjustable within defined limits.

A discussion of the term “vacuum” as a material-free ideal case and its relation to the term “dielectric” in the sense of a “material constant” is not necessary here because 100 to 1000 molecules per cubic centimeter are still present as “material” in a high vacuum.

Structure and special features

Vacuum capacitors consist of two concentrically arranged, cylindrical electrodes with usually several cylinders mounted on a base plate. In the case of capacitors with a fixed capacitance value, these cylinder electrodes are pushed into one another concentrically without touching one another. In vacuum capacitors with adjustable capacitance values, a cylindrical rotor electrode is rotated concentrically into a stator electrode. Due to the cylindrical design of the electrodes, maximum volume utilization of the likewise round, hermetically sealed housing is achieved. Glass or a special ceramic is used as the material of the surrounding housing. As is customary in tube technology , the condenser is evacuated and sealed with suitable pumps. Depending on the current-carrying capacity, the capacitors can also be provided with tubes in the housing for air or water cooling.

The distance between the electrodes of opposite polarity depends on the dielectric strength of the capacitor. But it is not just the electrode spacing that defines the dielectric strength; the surface properties of the electrodes also play a role. Mechanical unevenness on the electrode surface can promote spark discharges due to field emission . To reduce this effect, the surfaces of the electrodes can be mechanically ground and also electrolytically passivated.

Because of the very high alternating currents that can occur in the capacitor when a transmitter oscillating circuit is in operation and which result not only in high electrical but also very high mechanical loads on the internal structure of the capacitor, the mechanical structure of the electrodes must be very robust and stable. In order to keep these mechanical loads as low as possible, “non-magnetizable” vacuum capacitors, the electrodes of which are made of special, non-magnetizable alloys , are used.

Fixed capacitance vacuum capacitors

As described above, vacuum capacitors with a fixed capacitance value (fixed value vacuum capacitors) consist of two concentrically arranged cylindrical electrodes with usually several cylinders mounted on a base plate, which are pushed into one another concentrically without touching one another. Vacuum capacitors with a fixed capacitance value are used as HF power capacitors (high frequency capacitors ) in transmitters with powers above about 10 kW in resonant circuits to generate transmitter frequencies for commercial and industrial transmitters. They are offered with capacitance values from 10 pF to 6000 pF, are usually specified with a capacitance tolerance of ± 5% and have nominal voltage values up to 90 kV. Vacuum capacitors with a fixed capacitance value have a very high current-carrying capacity due to their robust construction with very low internal ohmic losses. As high-frequency capacitors in this application, they are in competition with HF ceramic power capacitors. However, vacuum capacitors can still be operated with convection cooling at the highest loads if ceramic power capacitors would have to be operated with forced cooling. Vacuum capacitors can also be used at very great heights without any problems. Due to the hermetically sealed vacuum in the condenser, these components can be used almost independently of the external air pressure.

The higher price of vacuum capacitors compared to ceramic high-frequency capacitors has a disadvantageous effect. The temperature behavior of the capacitance, which, depending on the housing material, is given as around 50 to 100 · 10 −6 K −1 , could also be a disadvantage if the temperature profile of the inductance in the LC circuit requires a different profile in order to obtain a temperature-stable frequency.

Variable vacuum capacitors

Variable vacuum capacitors are rotary capacitors whose capacitance value can be continuously adjusted within defined limits. They are structurally similar to the "submersible trimmers", an invention by Philips from the 1930s, but in terms of performance they complement the field of rotary air condensers much more. However, variable vacuum capacitors are significantly smaller than rotary air capacitors.

Variable vacuum capacitors, like vacuum capacitors with a fixed capacitance value, have cylindrical electrodes with mostly several cylinders mounted on a base plate. One of these cylindrical electrodes, the stator, is mechanically fixed to the housing. The second electrode, the rotor, is screwed into the cavity in the stator electrode with the help of a thread on a central axis. In order to maintain the vacuum during the adjustment process, the screw thread of the rotor is enclosed within the housing with a hermetically sealed metallic bellows-type sleeve.

Variable vacuum capacitors are designed for more frequent actuation. The thread on the rotor axis enables the desired capacity value to be set with an angle of rotation greater than 360 degrees. The disadvantageous, geometrically determined linear capacitance curve of the immersing rotor, which does not comply with the oscillatory circuit laws, is compensated for by the large angle of rotation. In addition, variable vacuum capacitors can have very large, continuously adjustable capacitance ranges. The ratio of the minimum to the maximum capacity can be up to 1: 150. The drive of the rotor, which often has to be done during the transmission operation, can be done manually, but is often mostly done by a controlled motor drive.

Variable vacuum capacitors are significantly smaller in terms of their dimensions than rotary capacitors with an air dielectric. The hermetically sealed housing also prevents the gaps between the electrodes from being soiled by dust and insects, which occurs when the air rotary condenser is unprotected, which significantly reduces the dielectric strength of the rotary condenser. The influence of changing air humidity, which in air condensers definitely causes changes in the condenser properties, is also excluded with hermetically sealed vacuum condensers.

Variable vacuum capacitors are used in high-frequency transmitters with powers above about 10 kW for frequency-dependent impedance matching. They have capacitance ranges from around 3 pF to a maximum of 6600 pF and can be operated with voltages up to 90 kV and currents up to 1 kA. The largest and most powerful capacitors have a device for water cooling.

properties

quality

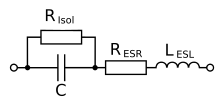

The mechanically robust construction of vacuum capacitors has the positive effect: The ohmic losses in the capacitor are very low due to the large cable cross-sections. The more compact design of vacuum capacitors compared to air capacitors also helps to reduce internal ohmic losses. Together with the very low dielectric losses of the vacuum, this results in the very low R ESR of vacuum capacitors with the consequence of a very high current carrying capacity.

In general, the ohmic losses of a capacitor are given by the R ESR , usually called ESR (Equivalent Series Resistance) for short, or the loss factor tan δ. In the case of vacuum capacitors, its reciprocal value, the quality factor Q, is specified instead of the loss factor . A high quality value corresponds to a small bandwidth B at the resonance frequency f 0 of the capacitor. Since the course of the impedance curve in the resonance range is steeper the smaller the tan δ, large numerical values of the quality provide a clearer statement about the ohmic losses of the capacitor.

The extremely low ohmic losses of vacuum capacitors lead to very high quality values. Quality values from 1000 to 5000 or even higher are specified in the respective data sheets. These quality values correspond to ESR values from 5 to 20 mΩ. In comparison, NP0 class 1 ceramic capacitors with a nominal capacity ≥ 50 pF have a quality of 500 (minimum value according to the applicable standards IEC 60384-8 / -21). However, if the cooling of a system is to be calculated, it makes more sense to consider the ESR of the condenser. With the ESR, the power loss P for the current I can be calculated directly using the equation P = I 2 · ESR .

The ESR of vacuum capacitors is frequency dependent.

Temperature dependence of the capacity

In order to precisely maintain a transmission frequency generated with an LC resonant circuit over a wide temperature range, the characteristic values of the components, in the case of capacitors this is essentially the capacitance, must have as little dependence on the temperature as possible. Vacuum capacitors have this very low temperature dependence of the capacitance value. The manufacturers' data sheets give values that roughly correspond to the values N33 to N150 for class 1 ceramic capacitors. For vacuum capacitors with ceramic housings, temperature coefficients around 50 · 10 −6 K −1 , for capacitors with glass housings around 100 · 10 −6 K −1 are given.

Web links

Footnotes and individual references

- ↑ Technical data of the vacuum capacitors from Comet, Vacuum Capacitors ( Memento from March 30, 2009 in the Internet Archive )

- ↑ Technical documents from Kunshan Guoli Vacuum Electric Co., Ltd. (GLVAC) on vacuum capacitors, archived copy ( memento of the original from January 22, 2016 in the Internet Archive ) Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice.

- ↑ Technical documents from Omnicor (Meiden) on vacuum capacitors, archived copy ( memento of the original from May 3, 2014 in the Internet Archive ) Info: The archive link was automatically inserted and not yet checked. Please check the original and archive link according to the instructions and then remove this notice.

- ↑ Technical documents from Greenstone, USA on vacuum capacitors, archived copy ( memento of the original from July 25, 2008 in the Internet Archive ) Info: The archive link has been inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice.

- ↑ Technical data from WVS on vacuum capacitors, archived copy ( memento of the original from January 20, 2009 in the Internet Archive ) Info: The archive link has been inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice.

- ↑ Properties of the vacuum dielectric, Jennings, [1]

- ↑ Jennings (ed.): Electrolytic polishing .

- ↑ Size comparison between a variable capacitor and a variable vacuum capacitor, [2]

- ↑ Applications of vacuum capacitors, Jennings, [3]

- ↑ Jennings (ed.): Quality Factor (Q) .