Belt drive

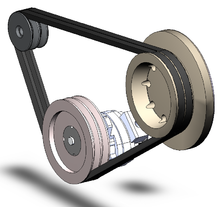

The belt drive (also the belt drive or belt drive ) is a traction mechanism with an i. d. Usually closed belts as a means of transferring movement or power between distant gear parts .

commitment

Belt drives used to be called Transmission . Classic transmission is extremely rare today. The development of especially small and powerful electric motors and safety aspects (danger of belt rupture) have displaced the classic transmission from industrial companies.

In modern belt drives, the flat belt has been largely replaced by the V-belt , as this can transmit large forces with a small pretension. When used, it also takes on the function of a safety clutch . Belt drives are used e.g. E.g. in the motor vehicle to drive the generator , in washing machines or machine tools as well as in the Doriot linkage to operate dental drills. However, it is no longer used for overcoming long distances. It is also used as a coupling for simple applications. A tension pulley is loosened and the otherwise tensioned belt slips through. (Use, for example, as a wheel drive for lawnmowers .)

However, the development of new types of belts, such as drive belts , has been preserved in various designs that retain the advantages of transmission and outweigh the disadvantages or for which they are not relevant in a special case.

The advantages of the belt drive are for example:

- quiet and quiet running

- Shock absorption

- low maintenance (no lubrication)

- low costs (especially with large shaft distances),

- short-term overload capacity (belt slip - not with toothed belts )

- low weight / performance

- high rotational speeds (revolutions)

The disadvantages:

- limited temperature range

- Belt stretching (retensioning)

- Sensitivity to external influences (oil, gasoline, temperature, dirt, water, dust)

- constant elongation slip (approx. 2% - not with toothed belts)

- large shaft loads (1.2–2.5 times the circumferential force ) depending on the type of belt

Due to the high risk of injury, transmissions (belt and gear drives) may only be operated in a house (boxes or grids).

Due to possible electrostatic charges from charge separation and the resulting discharge sparks, belts in potentially explosive areas must be electrically conductive and therefore grounded.

Classification

Belt drives can be divided into different categories:

By type of strap

According to belt guide

Open

Open belt drives are the simplest type. With them, the belt runs over two pulleys whose axes are parallel and whose direction of rotation is the same. The direction of rotation is easily reversible. Very high belt speeds can be used.

Crossed

Crossed belt drives are used when the pulleys are to move in opposite directions of rotation. You need a relatively large distance between the pulleys and must be designed so that the strands of the belt do not touch.

Half-crossed (crossed)

With set belt drives, rotary movements can be transmitted from two axes, which are arranged at an angle of 90 ° to each other (just like a worm gear). Their distance does not have to be as great as in the case of the crossed arrangement, since there is no risk of the two sides of the belt touching.

Multiple drives

The belt usually runs over a drive belt pulley and several output shafts and / or pulleys.

Classification according to clamping options

Expansion gear

The belt is shorter than actually necessary and is stretched elastically .

Tension pulley gear

There is one or more additional tensioning pulleys on the slack strand. The tensioning pulleys can be either fixed or spring-mounted.

Expansion shaft gear

With the expansion shaft transmission, the input or output shaft or the motor or the machine can be moved in its holder in order to tension the belt. A well-known application is in the automotive alternator drive.

Automatic clamping

- Motor fixed on rocker (self-tensioning belt drive according to Josef Pöschl or self-tensioning "Sespa" drive) - tension through the reaction torque of the motor as a result of the torque, idle preload mostly also through the motor and rocker mass.

- Drive pulley connected with gear to motor shaft. The drive shaft can be pivoted around the motor shaft. The reaction torque of the motor swivels the drive pulley and thus tensions the belt.

According to adjustability / switchability

Release gear

The release gear corresponds to the clutch for flat belts explained above for the classic transmission.

Step washer

It is used to build manual transmissions with belt drives. See also classic transmission (flat belt) application in machine tools. However, switching is often done at a standstill.

Conical disk

Two opposite conical bodies of revolution on which a slightly wider belt is moved in the axial direction. It is the simplest of all continuously variable ( CVT ) belt drives.

V-belt adjustment gear

Infinitely variable transmission (collective term CVT transmission ) in which a wide V-belt runs between axially adjustable bevel gears. Use in small motorcycles and pillar drilling machines . See also Variomatic and chain transmission .

Norms and standards

A selection:

- Diameter: DIN 114

- Couplings: DIN 115 , 116

- Storage and storage documents: DIN 117 , 118 , 119 , 187 , 189 , 193 , 194 , 195

- Drive pulleys: DIN 109 , 110 , 111 , 112 , 121

- Anchoring: DIN 188 , 191 , 192 , 261 , 794, 796

- Countershaft: DIN 751, 752, 753, 754, 755, 756, 757

- Symbols: DIN 991, 992, 993

literature

- Thomas Nagel: Toothed belt drive: properties, standardization, calculation, design. Hanser, Munich 2008, ISBN 978-3-446-41380-1 .

- Traction drive. In: Waldemar Steinhilper, Bernd Sauer (Ed.): Construction elements of mechanical engineering 2: Basics of machine elements for drive tasks. 6th edition. Springer 2008, ISBN 978-3-540-76653-7 , pp. 571-636. (Excerpt) in the Google book search

Web links

- Machinelenelemente III - Lecture of the University of Siegen , chapter traction mechanism