Flat belt

Flat belts are drive belts with a flat, mostly rectangular cross-section. They achieve a very high level of efficiency (up to over 98%), but are now only found in small drives ( e.g. tumble dryers , tape recorders , record players ).

Flat belts used to be made primarily from leather. Later on, rubber fabric straps replaced the leather straps, as they are much more dimensionally stable and less sensitive to moisture. These belts can still be found today in sawmills or small hydroelectric plants. Today flat belts are often made of plastic ( polyamide , polyester or aramid ). Today's flat belts contain solid synthetic fibers or steel wires inside. To increase the coefficient of friction , they are often covered with rubber. With the same surface and envelope thickness on both sides, they can drive flat belt pulleys with both the front and the rear.

Flat belts played a major role in industrialization in the 18th and 19th centuries. By means of waves, which mostly ran along the ceiling of the factory building (see transmission ), the power of a central drive - usually a water wheel or a stationary steam engine - was fed to a wide variety of applications via the belt. With the advent of motors ( electric or compressed air motors ), there was a change to the individual drive of machine tools , so the mechanical energy distribution by means of transmission was increasingly displaced and is now only found occasionally in some developing countries.

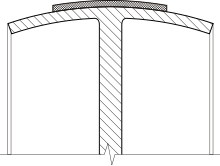

To prevent the belt from running off the pulleys, the running surface of the pulley is slightly arched outwards ( crowned ); the belt centers itself in this way (later standardized in DIN 111: 1982-08 ).

In the water turbine area , gears with a 1000 mm wide flat belt up to 1.5 MW were transferred.

Connection of the ends

The leather straps were usually screwed on the ends for heavier belt or the ends were Klammerösen ranging from sheet metal or clip claws wire (see figure), the belt lock , fogged , and by a metal round bar, the lock pin connected with each other. This metal connection point produced a monotonous “clack, clack” every time the pulleys were touched. The speed could therefore also be recognized from the tone sequence. 'Slow' meant heavy gear / load and 'fast ' meant idling .

Later, flat belts were either ground beveled or split into the individual layers and glued at an angle , whereby a higher mileage was achieved. The detachable connection, however, had the advantage that it could be placed in inaccessible places without removing the drive pulleys, since they were connected on site. After these flat belts had been in operation for a long time, they were pressed smoothly by the pulleys. Against the smooth belt slippage this a (was adhesion -) belt fat applied to the flat belt, making the slippage diminished.

Today flat belts are produced in one piece. In the case of unreinforced rubber belts, this is possible through primary shaping; in the case of fabric-reinforced belts, synthetic fiber threads are wound in several turns and then covered with elastic , e.g. rubber .

- Flat belt connections

Typical connection design through metal eyelets on flat leather belts of a transmission from the beginning of industrialization

The Lederschäftung (adhesion) of short strips of leather, in order to obtain a very long drive belt, further comprising a Lederstreifen- seam provided

- Flat belts in use

Flat belts sewn with leather strips on a lathe

Web links

literature

- Frank Rieg, Manfred Kaczmarek: Pocket book of machine elements. Hanser Verlag , 2006, ISBN 3-446-40167-9 .

- Dieter Muhs: Machine elements . Standardization, calculation, design. Vieweg + Teubner Verlag , 2007, ISBN 3-8348-0262-X .

Individual evidence

- ^ Frank Rieg (ed.): Pocket book of machine elements . Hanser, 2006, ISBN 3-446-40167-9 , pp. 415 ( limited preview in Google Book search).

- ↑ Arch height max is only 0.3 - 1.0 mm depending on the diameter of the belt pulley.

- ↑ Crowning of belt pulleys ( Memento of the original from May 28, 2010 in the Internet Archive ) Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice. , Rim shapes for flat belt pulleys according to DIN 111 / ISO 100 ; PDF 410 kB.

- ↑ Belt grease

- ↑ Picture: Can with belt grease