Water turbine

A water turbine is a turbine that makes water power usable. In this case, kinetic energy and / or potential energy of the water by the water turbine in rotation energy converted, causing the rotation of the turbine shaft. This rotation is usually used to drive a generator to generate electricity , but was previously also used for the direct drive of work machines or the drive of transmissions .

technical basics

The power P (in watts ) of a water turbine is calculated in the so-called turbine equation from the efficiency of the turbine multiplied by the density of the water ≈ 1000 kg / m³, the acceleration due to gravity g ≈ 9.81 m / s², the height of fall h (m) and the volume flow (m³ / s)

The efficiency varies depending on the type, age and operating point of the turbine. New Francis turbines achieve efficiencies of just over 94%, i.e. = 0.94.

The height of fall h is less than the actual height difference between the upper and lower water. It already takes into account the losses due to the friction of the water in the pipelines . It has the unit meter.

This relationship can be visualized by using the same formula for a pump that pumps water from the lower to the upper water. Carrying out of this pump to mechanical power, so that its rotating impeller, the efficiency calculated from the quotient of the power supplied and the product from . Here, however, the height is only the actual delivery height of the pump - this is also the case with the water turbine.

In a few hydroelectric plants, the rotation of the turbine is transmitted to a generator by means of a gearbox. In addition to the losses of the turbine, the losses through the gearbox are added and the mechanical power is calculated as follows:

The generator also has losses. The electrical power ultimately generated by the turbine is calculated from:

From the equations it can be seen that a large head can compensate for a low water flow and vice versa. This means: The relatively small amount of water in a mountain stream with a large head can sometimes generate more electrical energy than the large amount of water in a river, which can only overcome the height difference of a weir .

Turbine types

Impulse turbines

In constant pressure turbines , the water pressure does not change when it flows through the turbine: only kinetic energy from the flow speed is transferred to the impeller, which is reduced accordingly. This means that the underwater has to flow away with a correspondingly larger cross-section. The impulse turbines include the Girard turbine , the Pelton turbine (free jet turbine ) and the cross- flow turbine (e.g. Ossberger turbine).

Overpressure turbines

In an overpressure turbine , the pressure of the water is highest at the inlet and decreases until the outlet, so that primarily the potential energy from the height of fall is transferred to the impeller. This applies to the Francis turbine and the Kaplan turbine or their simplified design as a propeller turbine. Also for the diagonal turbine (e.g. the Deriaz turbine ), which was only rarely built. Diagonal turbines of the Lawaczeck design ( Lawaczeck turbine ) were installed in the American power station Grand-Coulee .

If (as in the case of the constant pressure turbine) the flow cross-section is increased at the same time and the flow speed is reduced, its kinetic energy can also be used. A diffuser has a similar effect in the downstream flow behind the turbine, the reduction of the flow velocity acting as suction (suction) on the pressure difference across the turbine.

Overview

| Turbine: | Pelton turbine | Cross-flow turbine | Francis turbine | Kaplan turbine | Propeller turbine | Diagonal turbine |

| Alternative names | Free jet turbine | Cross-flow turbine Banki turbine Michell turbine Ossberger turbine |

Propeller turbine with adjustable rotor blades |

Kaplan turbine with fixed blades |

Deriaz turbine Kviatovsky turbine Lawaczek turbine |

|

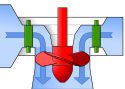

| Control elements shown in green in the graphics |

|

|

|

|

|

|

| Volume flow [m 3 / s] | ≈0.5-50 | ≈0.5-8 | ≈0.6-1000 | ≈2-1000 | ≈ 1-600 | ≈ 1.6-300 |

| Height of fall [m] | ≈100-2000 | ≈5-150 | ≈20-700 | ≈10-60 | ≈5–20 | ≈30-120 |

| Power [MW] | ≈0.5-250 | ≈0.025-1 | ≈ 0.04-1000 | ≈ 0.4-150 | ≈ 0.05-50 | ≈ 1-100 |

| Efficiency | up to 90% | approx. 80% | approx. 90% | up to 96% | up to 96% | up to 90% |

| operation area | Storage power plants | River power plants | universal | River power plants | River power plants | Storage power plants |

| Vulnerable to cavitation | No | No | Yes | Yes | No | No |

| Turbine type | Impulse turbine | Overpressure turbine | ||||

| Wave position | vertically or horizontally | horizontal | mostly vertical, rarely horizontal |

classic vertical as a horizontal bulb turbine |

horizontal or sloping |

vertical |

The heights of fall, volume flows and performance values were read from diagrams from Escher-Wyss (or Voith).

Also:

- Wells turbine for large amounts of water with periodically changing direction of flow for use in wave power plants

- Diagonal turbine , e.g. B. the Deriaz turbine , the Kviatovsky turbine and the Lawacze turbine , all overpressure turbines according to Paul Deriaz / Kviatovsky / Lawaczeck

and mainly for small hydropower plants :

- Hamann turbine for low flow velocity

- Water vortex turbine with slow speed for low gradients

- Low speed hydropower screw for changing flow rates

- Top-wing rotor with slow speed

Constructive details

In order to achieve optimum efficiency, the turbine must be adapted to the different heads and water flow rates. A storage power plant in the mountains therefore needs a different turbine than a run-of-river power plant on a river.

Water turbines are designed with outputs of around 200 watts up to a thousand megawatts. The turbines of the large power plants are individually designed and manufactured before they are finally assembled on the power plant construction site. The impellers of such turbines have a diameter of up to 11 m. However, water turbines cannot be miniaturized at will, since small turbines have a similar effort to regulate as large turbines and are particularly sensitive to water pollution .

A special feature of the water turbine is the elaborate control of its speed with the always slightly fluctuating water flow. The designed regulators keep the speed constant with hydraulically operated actuators ( fittings and guide vanes ) and also protect the turbine against " running away " if the torque on the generator shaft should drop, for example due to idling .

A speed control can be dispensed with in the case of small turbines in mains operation, since the generator is kept at a constant speed due to the mains frequency when feeding into the mains. In the event of a power failure, however, the water supply must be interrupted by means of flaps or guards to prevent runaway if the turbine and generator were not designed for idling speed. Normally this is about twice to two and a half times the operating speed.

The share of the turbine and controller in the total investment of a hydropower plant is considerable. This cost share is up to 50 % for small systems and 10 to 20% for large systems. On the other hand, water turbines are characterized by a long service life; machines have been in use in some power plants since the end of the First World War . In this case, they are among the technical monuments that are still in operation.

Pump turbines in modern pump storage plants

So-called pump turbines are increasingly being installed in pumped storage plants . They are alternating between water turbines and pumps , depending on the direction of flow in which they are flown (reverse direction of rotation). There are radial and axial to be built types. The aim is to minimize investment costs , reduce space requirements and optimize the hydraulic efficiency . Large radial pump turbines built today are said to look similar to the Francis turbines . Bohl points out that because of the energy losses from Euler's main equation, it follows that the speed in pump operation must be greater than in turbine operation. Quote: "The 'Kaplan pump turbines' installed in the Moselle power plant in Detzem should have a speed of 45% higher in pump operation than in turbine operation". At the same speed, a pump turbine as a pump would therefore pump a smaller volume flow in comparison with the volume flow that would flow through it in turbine operation at this speed.

The "Isogyre reversing turbine" (after. Fa.Charmilles) is also one of the pump turbines. According to the figure, it has a mirror-symmetrical impeller which can work as a pump or a turbine in both cases when the flow is flowing from one side or the other, depending on which direction the impeller shaft is rotating. In both cases, the only decisive factor is whether energy is taken from the shaft (turbine operation) or supplied (pump operation). The housing part of the Isogyren reversing turbine through which there is a flow is also mirror-symmetrical.

For delivery heights / impact water heights of more than 90 m, diagonal turbines according to P. Deriaz are also used as pump turbines (probably types with adjustable guide vanes).

Technology history

The technological-historical predecessors of the water turbines were water wheels with a vertically arranged shaft , which came into use in the 18th and 19th centuries. The name turbine comes from Claude Burdin (1790–1873), who called his invention that in 1824. In 1826 the French Société d'encouragement in Paris had advertised a price of 6,000 French francs for the manufacture of turbines. The first applications were unsuccessful until it was not until 1833 that the French engineer Benoît Fourneyron succeeded in acquiring the prize with the turbine named after him, the theory of which was determined by Jean-Victor Poncelet in 1838 .

The Fourneyron turbine (from 1833)

The Fourneyron turbine works in a similar way to the Francis turbine that followed later, except that the guide vanes have a fixed position and the water flows from the inside onto the impeller on the outside. (In Francis turbines, the water flows from the outside to the inside and the stator is on the outside.) The design was well suited to uniform water inflows and prevailed against the undershot water wheel within a few years . With an optimal water throughput, the turbine efficiency reaches 85%. Despite its simple structure, it is no longer manufactured today. In order to be able to adapt the Fourneyron turbine to the available process water, a movable cover was attached along the inside of the outer blades, with the help of which the water flow could be changed.

The Fourneyron turbine has been improved several times:

- 1837 by the German Karl Anton Henschel

- 1838 by the American Samuel B. Howd , who relocated the impeller inside the tail unit

- by the Englishman James Thomson (1822-1892), who developed the adjustable guide vanes and the curved impeller blades

Museums on hydropower & turbine technology

- The information center at the power plant in Hemfurth-Edersee on the Edertalsperre provides information about the formation of the Edersee and the function of pumped storage power plants . On guided tours that can cavern power station Waldeck include II.

- of mining in the Harz was associated with extensive use of hydropower ( return wheels , water drainage gallery , etc.) that in many places the electricity is used and documented in numerous museums and tourist attractions (see: Harz Water shelf ).

Ziegenrück Hydroelectric Museum

One of the oldest run-of-river power plants in Germany (around 1900), the Fernmühle, is located in Ziegenrück in Thuringia . It is operated as a museum and partly still actively used to generate electricity. The functionality of the generation of electrical energy by means of water turbines is conveyed on the basis of preserved old systems (some only preserved for demonstration purposes) as well as the new technologies of large hydropower plants at dams. An extensive open-air exhibition of various water turbines is shown in the grounds of the Ziegenrück hydroelectric museum. The Ziegenrück hydropower museum should not be confused with the disused Conrod power station in Ziegenrück.

Calculation of turbines

See:

literature

- Adolf J. Schwab : electrical energy systems. Generation, transport, transmission and distribution of electrical energy. Springer, Berlin a. a. 2006, ISBN 3-540-29664-6 .

- Georg Küffner (Ed.): From the power of water. Deutsche Verlags-Anstalt, Munich 2006, ISBN 3-421-05898-9 .

- Julius Weisbach: Textbook of Engineering and Machine Mechanics, Second Part: Practical Mechanics, Verlag Friedrich Vieweg u. Sohn, Braunschweig 1846, Chapter Four "From the vertical waterwheels" pp. 154–243, Strauberad (Figs. 219 and 220) and Staberad pp. 201–202; Chapter five "From the horizontal waterwheels" (turbines) pp. 243–334 (geometric structure and calculation of many different waterwheels and turbines)

- Willi Bohl: Turbo machines 1, structure and mode of operation, Vogel Fachbuch Verlag Würzburg, 8th edition 2002, ISBN 3-8023-1935-4 , Chapter Seven: Water turbines P. 111-135 (structure, calculation, characteristic fields / areas of application, and sectional drawings by Water turbines)

Web links

Article on the diagonal turbine with a picture of a Deriaz turbine info page on the Deriaz turbine

Individual evidence

- ↑ Willi Bohl: Turbo machines 1, structure and mode of operation, Vogel Fachbuch Verlag Würzburg, 8th edition 2002, ISBN 3-8023-1935-4 , classification of water turbines according to the mode of operation p. 113

- ↑ Willi Bohl: Turbo machines 1, structure and mode of operation, Vogel Fachbuch Verlag Würzburg, 8th edition 2002, ISBN 3-8023-1935-4 , classification of water turbines according to the mode of operation p. 113

- ↑ Willi Bohl: Turbo machines 1, structure and mode of operation, Vogel Fachbuch Verlag Würzburg, 8th edition 2002, ISBN 3-8023-1935-4 , classification of water turbines according to the mode of operation p. 113 u. 130, diagonal turbine or Deriaz turbine

- ↑ Peter Hakenesch: Flow of fluids. Chapter 4, Part 3. In: Slides for the lecture Fluid Mechanics. P. 45 , accessed on February 4, 2016 .

- ↑ Willi Bohl: Turbo machines 1, structure and mode of operation, Vogel Fachbuch Verlag Würzburg, 8th edition 2002, ISBN 3-8023-1935-4 , diagram 7.4 / S. 114 and diagram 7.5 / p. 116, operating range of water turbines

- ↑ Willi Bohl: Turbo machines 1, structure and mode of operation, Vogel Fachbuch Verlag Würzburg, 8th edition 2002, ISBN 3-8023-1935-4 , classification of water turbines according to mode of operation, diagonal and deriac turbine p. 113 u. 130

- ↑ Willi Bohl: Turbo machines 1, structure and mode of operation, Vogel Fachbuch Verlag Würzburg, 8th edition 2002, ISBN 3-8023-1935-4 , Chapter: 7.8: Pump turbines (in pumped storage plants) pp. 133-135

- ↑ Willi Bohl: Turbo machines 1, structure and mode of operation, Vogel Fachbuch Verlag Würzburg, 8th edition 2002, ISBN 3-8023-1935-4 , Isogyre reversing turbine p. 116

- ↑ [1] Use of the Deriaz turbine as a pump turbine

- ↑ https://www.edersee.com/de/erleben/ausflugstipps/infozentrum-100-jahre-edersee Info center at the Hemfurth-Edersee power plant

- ↑ wasserkraftmuseum.de Homepage of the hydroelectric museum in Ziegenrück

- ↑ Information page from the State of Thuringia on the Ziegenrück hydropower museum