Hand drill

As a hand drill hand-held are drills referred. Depending on the design, they are suitable for drilling in different materials such as metal, plastic, wood, masonry, concrete or rock.

A common feature of all hand drills is the ability to insert drills and other rotating tools into a drill chuck that is generally attached to the face .

The hand drills are distinguished by a number of typical features.

Propulsion and general characteristics

The most important differentiating feature for hand drills is the type of energy supply, which can be done manually by hand using muscle power , electrically, hydraulically or pneumatically . Drilling machines for very high performance are predominantly hydraulically driven; Because of their weight, they cannot be carried by hand and are therefore not explained further in this article.

Manually operated drilling machines are rarely used anymore, because on the one hand it is much more convenient to have the drilling performance performed by an electric or pneumatic drive and, on the other hand, precise guidance of the drill is difficult if you have to crank at the same time. Even in places where no electricity or compressed air is available, battery-powered devices have now replaced hand-operated ones.

Pneumatic hand drills are particularly common in the industrial environment on many production lines and assembly line workstations. They can be built small and light, and blocking is not critical, as is damage to the supply line.

An electric or pneumatic drill can achieve much higher speeds and a much higher performance and thus a higher cutting speed than a manually operated hand drill.

The weight of a hand-operated drill is usually less than that of a motor-operated device. It can also be operated more safely and independently of the power grid.

In many electrical and almost all pneumatic machines, a maximum torque can be set in order to reduce the risk of drill breakage.

For further general properties of drilling machines see also the article drilling machine .

Electric

According to the type of power supply, electrically driven drills can be divided into models with built-in accumulators (independent of the mains ) and models that have to be connected directly to the mains and can therefore only be operated in a mains -dependent manner.

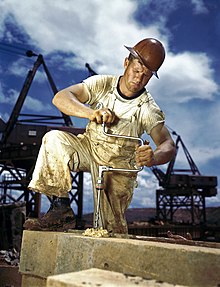

The device is held and guided by hand while drilling . In addition to electric and pneumatic hand drills, there are also hand-operated devices such as the drill winch . To safely guide the machine at high torques, an additional handle can often be attached just before the drill chuck for the other hand. Often a depth stop can also be installed to limit the drilling depth. In the machine shown in the top picture, a switch can be used to switch between two gear gears in order to drill at low or high speed. Many devices also have a stepless electrical power controller (often called a "speed controller") with which the torque and speed can be influenced.

Impact drill

A hammer drill has a hammer mechanism (which can usually be switched off), which exerts short-stroke axial blows on the workpiece to be drilled via the drill head with a high number of blows. Many hand drills - designed as impact drills - are equipped with a switchable, integrated impact drilling device.

Impact drilling is almost always necessary for drilling in stone , masonry and concrete .

The hammer mechanism almost always consists of ratchet teeth on the drill spindle. The effectiveness is only achieved through high pressure. System- related wear of the teeth occurs. A hammer drill is more suitable for frequent drilling in concrete.

Rechargeable drill

Cordless drills (see also cordless tools ) are cordless hand-held (impact) drills. Their areas of application are mostly light work in wood, plastic and metal. Most cordless drills do not have a hammer mechanism, so they are not suitable for drilling into hard rock or concrete.

Hammer drill

The hammer drill is a drill that is specialized for drilling in stone and concrete as well as for chiselling work. The number of blows here is significantly lower than with the impact drill, but the impact energy is much higher. In contrast to the impact drill, the blows are generated by a pneumatic hammer mechanism, which enables a higher impact energy. At the same time, the required holding force by the operator is lower than with a hammer drill with the same drilling capacity.

Manually

The simplest type of "hand drill" is not a machine , but rather a tool ( awl , racing spindle ( Dreule ), nail drill , drill bit ) that is provided with a slight gear (see drill ).

Simple hand drills operated exclusively with muscle power (manual feed and cutting movements) usually hold drills with a diameter of 2–15 millimeters. There are crank handles or devices with gear (often switchable) and side crank. Here twist drills , Forstner bits or auger bits are used, which were clamped in a two-jaw chuck (drill end rectangular or square), later in a three-jaw chuck .

Watchmakers in particular used pillar drills driven by a belt via a pedal for the smallest bores .

Hand crank drill / drill winch

Hand crank drills have a main handle and a side handle. If high pressure is required when drilling due to the hardness of the material, you can z. B. with your stomach against the main handle.

To drill , turn the side handle in the direction of rotation of the twist of the twist drill. If the drill tries to break out against the drilling direction, this movement can be counteracted directly on the side handle.

Breast veil

A breast vault is a manual drill that can be operated with both hands , in which the cutting movement (rotation of the drill) is generated using a hand crank , while the feed force is generated by means of muscle power through pressure on the impression surface opposite the drill chuck with the help of another body part . A breast vault has a gear , which allows a higher speed of the drill to be achieved. However, this additional machine element reduces the efficiency of the entire drilling system, but in many cases enables two different gears to be used by simply repositioning the hand crank on the gear shafts guided out of the housing.

Special forms

Angle drill

In the case of the angle drill, the drill chuck is not at the front, but is rotated by 90 °. This design can also be used to drill in places that are too narrow and offer no space for the drive part of the hand drill. Alternatively, an angle drill attachment can be clamped into the drill chuck of a normal hand drill, which also has a drill chuck that is rotated by 90 °.

receipt

- Special Edition of Do It Yourself , The Readers' Digest Handbook for Hobbyists (p. 66). (c) 1975 Verlag Das Beste GmbH, Stuttgart, for Tchibo fresh roasted coffee Max Herz, Hamburg