CMS electrode

The Corrosion Monitoring System electrode ( CMS electrode for short ) is a silver-silver chloride electrode and thus belongs to the second type of electrodes . It is processed in the form of long wires and is used, for example, to measure corrosion and also the risk of corrosion of the steel reinforcement in reinforced concrete or in the case of stranded or bar steel in anchors in various structures.

construction

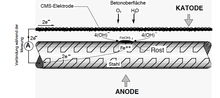

This type of electrode is a silver wire coated with silver chloride that is wrapped in a braid. The electrode is laid in concrete or cement mortar near the steel reinforcement . The pores of the cement paste or concrete are filled with water, which functions as an electrolyte solution . This ensures a minimal ion flow that is sufficient to set the redox equilibrium on the electrode surface. The measuring device or the reference electrode input of a potentiostat has a very high resistance, so that no currents worth mentioning arise here.

Applications

In practical application, CMS electrodes are used, for example, to measure the corrosion and also the risk of corrosion of steel in concrete or cement paste.

CMS electrodes are used in bridge construction to monitor the corrosion of components that are very heavily stressed with road salt. If corrosion is discovered, cathodic corrosion protection can prevent further corrosion from spreading.

With anchors the geotechnics CMS electrodes are used successfully for the 1995th The static system of the anchors can be disturbed by two occurrences: displacement of the subsoil or corrosion of the anchor.

The stress on the anchors changes when the terrain is shifted and it must be checked whether forces occur in the permitted area or not. This can be checked by observing and measuring the components to which the anchors are fixed. If necessary, a force measurement can be carried out.

If corrosion occurs in anchors, the steel cross-section is reduced, which means that the required safety is lost and ultimately leads to the anchor breaking. With a CMS electrode, this corrosion is very easy to check along the entire anchor; Countermeasures can be taken early on.

It turns out that in practice only the recurring corrosion measurement should be carried out on anchors. In this way, with a very favorable control, you have the entire anchor-structure system under control with regard to the maintenance of a structure. Several hundred anchors are already equipped with the CMS electrode and have been successfully monitored since 1993. The countries of operation are Austria, Germany, Switzerland, the USA and Canada.

literature

- Bernhard Wietek : Monitoring the Corrosion of Steel in Concrete . Concrete Society, London 1996.

- Bernhard Wietek: A corrosion measuring system for permanent anchors . GD anchor colloquium 1996.

- Bernhard Wietek: Early detection of corrosion on bridges . VÖZ Colloquium Research and Development for Cement and Concrete, Vienna, November 4, 1997

- Bernhard Wietek: Detecting the size of the corrosion areas on tendons with the help of electrodes . Final report research project 3525 BMWA, February 2000.

- Lazzari et al .: "Laboratory testing on linear-continuos-reference-electrode type". Dipartimento di Chemica, Politecnico di Milano, EuroCorr 2003.