Compressed air cylinder

The compressed air cylinder (also compressed air cylinder or breathing air cylinder ) is a gas cylinder for compressed air. Applications include use as a breathing gas storage container or as an energy storage device and expansion tank for technical systems and machines.

Uses

In industry and commercial operations, compressors are used to generate compressed air directly . Compressed air cylinders are used where this is not possible or when large quantities are required in a short time, for example when starting large combustion engines (diesel engine / gas turbine).

In addition, compressed air cylinders, a part of compressed air diving apparatus for divers (colloquially diving or diving bottle ) and self-contained breathing apparatus for firefighters and many other users. Special breathing gas mixtures are also stored and transported in compressed air cylinders. This is called, although it is the same container, a nitrox , oxygen or trimix cylinder, depending on the contents.

The compressed air cylinder consists of a pressure vessel made of steel , aluminum or a composite, a thinner steel inner body that is reinforced with fiber- reinforced plastic .

Compressed air cylinder for breathing apparatus

The cylinder bodies of compressed air cylinders for breathing apparatus have a small conical, large conical (both outdated) or cylindrical bottle thread into which the shut-off valve is screwed. The conical thread is sealed with Teflon tape , the cylindrical with an O-ring . Conical threads can widen and destroy the bottle neck if they are improperly installed with excessive torque. The regulator and / or a bridge for connecting several compressed air bottles is screwed onto the shut-off valve . These valves are common in various designs:

- as a single valve for a regulator

- as a double valve with a second connection for a reserve breathing regulator ( octopus )

- as a bridge valve to connect usually two bottles to a package.

When the cylinder is full, the breathing gas is usually under a pressure of 200 bar . There are also special pressure vessels that can be filled to 300 bar. These have a different, longer thread, which is increasingly becoming the standard in Europe. In addition, 300-bar regulators are downwardly compatible with 200-bar devices.

The fire brigade and the THW use devices made from two 4-liter bottles (200 bar) or one 6-liter bottle or 6.8-liter bottle (300 bar). The double-bottle devices with 4-liter bottles are, however, out of date and are being replaced by the newer 6-liter devices or 6.8-liter devices. It should be mentioned that the 6-liter bottles are made of steel just like the 4-liter bottles and are therefore out of date, but are still popular in applications where high mechanical loads cannot be ruled out. They are considered to be more robust than the new composite bottles. In the meantime, manufacturers also offer 9-liter composite bottles. These 9 liter bottles are approx. 50 mm higher and thicker than the usual 6.8 liter bottles. They can be used in conventional breathing apparatus instead of the 6.8 liter bottle.

10 and 12 liter bottles have become popular with divers. There are also smaller or larger bottles with z. B. 15 liters available. Double bottles are also used.

Other uses

In addition to the uses mentioned above, compressed air cylinders are also used in paintball sports and for filling gully quick-release fasteners and lifting bags . In paintball sports, they are used to operate the markers . These bottles usually hold between 0.8 and 1.1 liters and are filled with 200 to 300 bar.

Bottles with a volume of several hundred liters and a pressure of up to 250 bar are quite common for starting ship engines. These are then permanently installed.

Incorrectly labeled as an oxygen cylinder

Oxygen cylinders are often incorrectly referred to in connection with scuba diving when they refer to compressed air cylinders. Divers generally do not use oxygen cylinders underwater. The breathing of pure oxygen has a toxic effect from a diving depth of more than 6 meters, since from this depth the partial pressure of oxygen would be above the critical limit of 1.6 bar. The result would be oxygen poisoning . In technical diving , however, pure oxygen is breathed as decompression gas at a depth of up to 6 m for a limited time. In addition, it is not uncommon to bring oxygen to the dive site or on a diving boat, which can be breathed out of the water by an injured diver until the rescue service arrives in order to mitigate the effects of his decompression sickness.

Regulations, standards and laws

Depending on the gas used, the compressed air cylinder may have to be marked with a dangerous goods sticker that shows the gas mixture used. This marking is to be applied to the bottle shoulder. In accordance with EN 1089-3, either a bright green shoulder for technical compressed air or a white bottle shoulder with a black ring that covers the lower half of the bottle neck can be used for compressed air for breathing purposes as color coding for compressed air. The cylindrical bottle body can be freely designed in terms of color. However, this regulation has not yet prevailed. Fire brigades in Germany, for example, continue to procure compressed air cylinders with yellow, black and white shoulders. Only the dangerous goods sticker remains binding in Germany.

For safety during storage and transport, valve protection is mandatory in Germany in the commercial sector, e.g. B. ventilated valve caps. This is regulated by the European Agreement on the Carriage of Dangerous Goods by Road (ADR) across Europe and by the Hazardous Goods Ordinance on Road, Rail and Inland Shipping ( GGVSEB ) in Germany. In Austria, in addition to the ADR, the StVO , the KFG and the Motor Vehicle Implementation Ordinance in road traffic are decisive. It should be noted that these laws and regulations may be binding on private individuals in the various countries. When transporting in a private car, it is sometimes only necessary to pay attention to the load safety according to the respective road traffic regulations, but sometimes the ADR also applies.

According to § 15 (7) of the German Industrial Safety Ordinance, diving equipment and breathing apparatus must be checked every 2.5 or 5 years; Bottles that fail this test may no longer be filled.

In Germany, these valve protection caps are not required for fire services . Instead, however, secure mountings are required both in the vehicles and in the areas of application, such as in the respiratory protection room. Transporting the bottles in private vehicles is always problematic, where these holders are not available as standard.

Bottle connections

Various connections are used in technical applications, and these must be approved by the respective certification authorities. In diving there are two common variants of the cylinder connection, the so-called INT and DIN connections.

- INT connector

- The so-called INT connection (English A-clamp or yoke ; wording of the standard: bracket output connection ) is the most widely used internationally . The connection is standardized according to ISO 12209: 2013.

- DIN connection

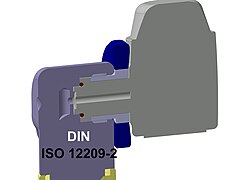

- The so-called DIN connection standardized according to DIN EN 144-2 / 3 and ISO 12209: 2013 (or earlier ISO 12209-2) is widespread mainly in the German-speaking area and among technical divers (wording of the standard: threaded output connection ). In contrast to the INT connection, the DIN connection is suitable for a cylinder pressure of up to 300 bar , instead of just up to 232 bar. The standard provides different thread lengths to differentiate between the maximum operating pressures. At 232 bar the thread length is at least 10 mm and at 300 bar at least 16 mm. This means that an automatic machine approved for 232 bar cannot be screwed tightly into a bottle suitable for 300 bar.

In Europe, respiratory protective devices usually have a DIN connection.

Regulator with DIN connection

See also

Individual evidence

- ↑ a b Transport security ( memento of the original from February 1, 2014 in the Internet Archive ) Info: The archive link was automatically inserted and not yet checked. Please check the original and archive link according to the instructions and then remove this notice. on the ÖBFV website of December 21, 2010, accessed on September 30, 2015.

- ↑ Transport security for the transport of breathing air bottles (compressed air bottles) in vehicles ( memento of the original from February 1, 2014 in the Internet Archive ) Info: The archive link was automatically inserted and not yet checked. Please check the original and archive link according to the instructions and then remove this notice. (PDF; 1.1 MB) of the ÖBFV from December 21, 2010, accessed on October 25, 2012.

- ↑ a b ISO 12209: 2013, iso.org: Gas cylinders - Outlet connections for gas cylinder valves for compressed breathable air (or earlier ISO 12209-3), accessed on September 3, 2013.

- ↑ Thomas Kromp , Hans J. Roggenbach , Peter Bredebusch : Practice of diving . 3. Edition. Delius Klasing Verlag, Bielefeld 2008, ISBN 978-3-7688-1816-2 , p. 237-238 .