Hammelmann GmbH

| Hammelmann GmbH

|

|

|---|---|

| legal form | GmbH |

| founding | 1949 |

| Seat | Oelde , Germany |

| management | Burkhard Helmig |

| Number of employees | 360 |

| sales | 93 million € (2015) |

| Branch | mechanical engineering |

| Website | Hammelmann GmbH |

The Hammelmann GmbH with headquarters in Oelde , Westphalia , is a manufacturer of plunger pumps, process pumps and high pressure cleaning equipment with subsidiaries in Spain, USA, Brazil, China, Australia and more than 40 agencies worldwide. The German company belongs to the Interpump Group from Italy.

history

Foundation and development until 1960

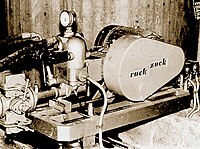

Paul Hammelmann founded the company in 1949. It was entered in the commercial register on March 1, 1949 . Initially, it manufactured bicycle parts, followed by contract work for electrical engineering. 1952 saw the first in-house production, a pulp mill for comminuting fodder, followed by the production of "quick and easy" construction elevators. In 1955 the first 3-plunger pump was built, specially developed for cleaning work in the paper industry. The next step was the automation of the screen, felt and suction roll cleaning by means of oscillating high pressure spray pipes. A high-pressure hose that got stuck during pipe cleaning work led to the construction of a pipe cleaning nozzle that can be automatically switched from pull to push. In 1958 the first patent for a device for automatic tank cleaning in the dairy industry was applied for. As a result, the company received numerous patents for high-pressure pumps and cleaning systems.

Technical developments since 1960

In 1969 ships were cleaned for the first time at the Wilton shipyard in Rotterdam with a semi-automatic device, the Hammelmann Dockmaster system. In 1974 the non-contact plunger seal was introduced. With the help of the metallic sealing system, pressures of 1000 bar with long service life were achieved for the first time. In 1978 high-pressure pumps were built in a vertical arrangement, the following year the construction of process pumps for pumping chemical liquids against high pressures began. In 1982, high-pressure pumps for concrete removal robots for bridge renovation and surface cleaners for stripping metal surfaces were added to replace chemical and sandblasting processes. The first high-pressure pump with a pressure of 2000 bar to operate a pressure vessel followed in 1984. Hammelmann has been building mobile high-pressure units with noise protection since 1988.

In 1991 Hammelmann received an environmental award for economical eco-concepts for a system for dust-free cleaning, rust removal and paint stripping of ship walls with a reduction of hazardous waste by over 90 percent. In 1992 Hammelmann developed surface cleaning devices with direct suction; an ES1 computer uses a microcontroller to control the entire high-pressure system to reduce water and diesel consumption. In 1993 Hammelmann developed gas-tight telescopic systems for the fully automatic interior cleaning of autoclaves, in 1995 pumps and accessories for deburring technology especially for the automotive industry and in 1999 tank washing devices for flow rates of up to 500 l / min at 1500 bar. The ergonomic spray gun in connection with transponder technology was awarded the German Occupational Safety and Health Prize in 2001 in the “innovative concepts” category.

In 2002, Hammelmann invented the bellows seal between the liquid part and the crank drive to hermetically seal the crank drive, and high pressure pumps up to 4000 bar were developed for cutting systems. In 2003, a high-pressure pump with delivery rates of up to 1760 l / min., Operating pressures of up to 3000 bar and drive power of 750 kW was launched. Further developments in 2005 were cleaning nozzles with manually adjustable speed and a new handle system for high-pressure spray guns that reduced the pull-off force by over 80%, in 2007 a device for stripping paint from ship floors and in 2008 a water tool specially designed for cleaning and stripping handrails and railings, and high-pressure pumps in 2010 ZeroEmission® version for pumping environmentally hazardous, explosive and toxic liquids and in 2011 a telematics system for locating Hammelmann systems via GPS and for permanent data access to the operating parameters via GPRS , regardless of the location of the system, as well as the introduction of 7 piston pumps for 1100 kW.

High pressure technology in industry

Deburring engine blocks

Paint stripping from ships

Disarming bombs using water-abrasive cutting

High pressure systems are used in almost all branches of industry. Here are a few examples:

Deburring engine blocks; Removal of particularly hard and / or thick-layered deposits from production facilities; Paint stripping of metal surfaces; Concrete repair , exposure of reinforcing bars ; Interior cleaning of autoclaves, containers, pipes, heat exchangers; Sewer cleaning ; Hydraulic longwall construction ; Water jet cutting ; Descaler ; Spray drying in the manufacture of coffee powder and detergents; Water needling of nonwovens ; Feed water pumps ; Production of modified polyethylene ; Secondary production of petroleum ; Injection of methanol as an anti-freeze agent in the production lines in the offshore extraction of oil and gas; High pressure extraction in the food industry

literature

- H. Müller-Steinhagen (Hrsg.): Handbook heat exchanger cleaning systems: Procedure for reducing and removing deposits and contamination. Publico Publ., Essen 2001, ISBN 3-934736-02-5 .

- Hans-Dieter Philipowski: Cleaning Technology. Storck Verlag, Hamburg 2008, ISBN 978-3-934782-30-3 .

Web links

- Official website of Hammelmann Maschinenfabrik

- Interpump Group , parent company of Hammelmann

Individual evidence

- ↑ Data and facts on hammelmann.de, accessed on April 9, 2018.

Coordinates: 51 ° 49 ′ 58.9 ″ N , 8 ° 9 ′ 16.4 ″ E