Hexagon socket

Allen (in German familiar under the brand name Allen ) is a carrier profile for screws with a hexagon ( Hex ) in the screw head . The corresponding wrench with an external hexagon profile is called an Allen key. In many countries the Allen screw is named after the Allen Manufacturing Company ( Hartford , Connecticut ) Allen screw, the Allen key or Allen wrench .

Brand name Inbus

The acronym Allen stands for " In nensechskantschraube B except u nd S chaurte". On the other hand, the spelling or pronunciation “Imbus” created by assimilation is common, but incorrect. The name is derived from the original manufacturer Bauer & Schaurte (in Neuss until 1980 ). Today the Inbus brand belongs to Inbus IP GmbH based in Breckerfeld . Tools and screws with the Inbus symbol are sold exclusively under license by Inbus Werkzeug GmbH and manufactured by them in cooperation with HaFu Werkzeugfabrik HJ Fuhrmann GmbH in Breckerfeld, Westphalia. In November 2018 INBUS, as one of a total of 250 German brands, received the award for the brand of the century from Zeitverlag for the first time .

Development and technology

William G. Allen patented a manufacturing process for screws with a hexagon drive profile in the screw head in 1910. In the USA, Allen keys are often referred to as "Allen key" or "Hex key".

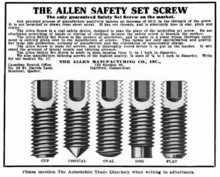

The Standard Pressed Steel Company (SPS) is said to have developed hexagon socket screws independently of Allen around 1911. SPS 'motivation was to develop locking screws without protruding screw heads and thus to increase machine safety. (Garments can get stuck on protruding screw heads; this risk is eliminated with a countersunk grub screw ). SPS square socket screws from Great Britain ( Robertson screws ), which SPS did not want to use due to costs and patents, served as inspiration . It is not known how SPS made the screws. Since Allen only held the patent for a specific manufacturing process, Allen’s patent could be bypassed if necessary.

Bauer & Schaurte patented this type of screw in Germany in 1936 and brought it onto the market. The technology was further developed and perfected by Walter Beduwé, who was the chief engineer at the time, among others.

With this type of screw, a hexagon socket is countersunk in a cylindrical screw head. Compared to a hexagon screw (with an external hexagon head), less space is required for the head. Compared to a cross-head screw of the same size , a hexagon socket screw can absorb around ten times the torque .

Properties and areas of application

Hexagon socket screws are well suited for screw connections in which the screw heads are difficult to access due to the design. It is sufficient if the head can be reached from above, for example through a hole whose diameter is larger than the corner dimension of the respective key. With keys with a spherical tip, the screws can be tightened and loosened even if the key and screw are not aligned . Hexagon socket screws can also be countersunk to save space if protruding screw heads interfere.

Allen key sets are inexpensive and compact in size. In addition, Allen keys can be easily extended with a tube in order to generate higher tightening and loosening torques. These properties make the hexagon socket screws the preferred screw for special machines .

Hexagon socket screws are often used on bicycles because they allow the tool kit to be kept small. The inexpensive Allen key can also be added by the manufacturer in a cost-saving manner with kits, for example for furniture. The socket head cap screw is characterized by a pleasing appearance, which is why it is often used for decorative purposes. In the case of everyday objects, the round shape has the advantage that hardly any parts or textiles can get caught on them and the risk of injury is lower.

A disadvantage of the hexagon socket when used outdoors is that dirt and water can collect in the cavity and lead to corrosion. In addition, the principle of the screw head is higher than that of a hexagon screw, but also narrower in diameter.

There are now screw drive systems that, compared to the hexagon socket, allow a better transmission of the tightening torque to the screw and permit higher torques, for example Torx from the USA or multi-tooth XZN according to DIN 34824.

standardization

Hexagon socket screws are available in different designs, which are also described in standards. The hexagon socket screws most commonly used in mechanical engineering are listed in the following standards:

- EN ISO 4026 (formerly DIN 913 ): Set screw with hexagon socket flat point

- EN ISO 4027 (formerly DIN 914 ): Grub screw with hexagon socket and point

- EN ISO 4028 (formerly DIN 915 ): Grub screw with hexagon socket and pin

- EN ISO 4029 (formerly DIN 916 ): Grub screw with hexagon socket and cup point

- EN ISO 4762 (formerly DIN 912 ): cylinder screw with hexagon socket

- EN ISO 10642 (formerly DIN 7991): Countersunk head screw with hexagon socket

- DIN 7984: cylinder head screw with low head and hexagon socket

- DIN 6912: Cylinder head screw with low head, key guide and hexagon socket

If the above versions are listed in technical documentation, then the designation according to the respective standard must be used. The size of the Allen key refers to the vertical distance in millimeters between two parallel sides of its hexagonal cross-section, which is also known as the width across flats, abbreviated to SW.

Similar head connection forms for screwdrivers

For the brakes, among other things, some car manufacturers use the rarer five socket screws instead of six socket head bolts. The matching hexagon socket wrenches are available from specialist dealers.

An inner pentagon also serves as theft protection for quick releases in bicycle technology , but these fastenings lose their actual quick release character. The tensioning lever is replaced by a removable internal pentagonal pin, which then has to be carried by the driver.

The internal multi-tooth (XZN) is also used in the automotive industry when particularly high tightening torques are required, for example for the cardan shafts in the drive train.

See also

Web links

- Description of the most important screw profiles. In: Bauen-und-Heimwerken.de. Retrieved on December 10, 2010 (screw profiles and the corresponding bit types).

- Stefan Schmitt: Ikea's Allen key is the hand ax of our time In: Die Zeit No. 41/2019 of October 2, 2019, edited online on October 4, 2019, accessed on October 4, 2019.

Individual evidence

- ↑ Information on the "Inbus" trademark in the register of the German Patent and Trademark Office (DPMA)

- ↑ deutsche-standards.de

- ↑ Patent US960244 : Manufacture of screws. Registered January 9, 1909 , published June 7, 1910 , inventor: William G Allen.

- ↑ Allen key in specialist shops. Retrieved September 4, 2012 .