Ball valve

A ball valve is a valve in which the directional effect is generated by a moving ball . In the typical application as a check valve , the ball prevents the fluid from flowing back through the valve. There are also spring-loaded versions as a pressure relief valve or as an automatic lock. Due to their simple construction and mode of operation, ball valves are used in large-scale systems as well as very widely in everyday consumer goods.

Sometimes (small) ball valves are incorrectly referred to as ball valves.

construction

In a ball valve, a ball closes the outflow ring of the valve, the so-called valve seat. There is only flow when the force on the underside of the ball is sufficient to lift it out of the valve seat. The ball is held in the area of the valve either by the mechanical construction of the valve housing or by a cage. There are only minor restrictions on the choice of materials for the valve seat, ball and cage, so that the components of the valve can be adapted to the substances to be regulated. An example of this is pulsometers for pumping acids, in which all components (pump housing and ball valves) are cast from lead.

As a rule, the ball is 1.4 to 1.5 times the size of the mean valve seat width. The valve seat is designed as an inclined surface and not as a spherical shell, so that there is only a linear contact between the ball and the seat. It is this limitation on a line which on the one hand an adhesion prevents the ball on the valve seat and on the other establishes the insensitivity of the ball valve with respect to particulate inclusions in the flowing matter: displacing the inclusions are from the approaching to the valve seat ball of the sealing line. Due to the inevitable rotation of the ball with the mass flow flowing through the valve, a different part of the ball always comes into contact with the seat. In combination with a suitable choice of ball and valve seat materials, wear can be limited to the ball. The spherical surface is thus worn evenly without the valve function being impaired by this wear.

Ball valves never seal completely during operation, but are never completely leaky when used in particle-containing contamination of the substances flowing through.

application

Ball valves are structurally simple and can therefore be implemented using different materials (e.g. glass). For these reasons, they are found in large numbers as an inexpensive design with small dimensions and in mass-produced articles or disposable packaging for daily use.

Because of the freely moving ball as a shut-off body, they are also more robust than comparable valves such. B. with flap . They are therefore often used in delivery lines for viscous substances (large forces) or when impurities in the substances flowing through could disrupt more complex mechanisms. In this case, ball valves do not necessarily close tightly. Due to the relatively free choice of materials for the ball, ball valves with suitable sealing materials can also be used in aggressive media such as acids and alkalis.

Consumer goods

In the filter coffee machine , heated water rises to the filter, as steam bubbles form in the heating element and displace the water. So that the water is not pushed back into the water tank instead, there is a ball valve at the inlet of the heating element. The valve opens and closes in a certain rhythm and can be heard as the typical clacking of coffee machines.

In the pump mechanism of spray bottles (e.g. for cleaning agents such as glass cleaners) and of cosmetic articles without propellants such as liquid soaps or lotions (here so-called scoop pumps ), the inlet valve is often designed as a ball valve with a spring-loaded plastic or metal ball.

Both the safety valve and the control valve of a pressure cooker can be designed as a ball valve. The preload of the spring (adjustable by Koch in the case of the control valve) determines the pressure that must be exceeded for the ball valve to open. In this way, the set pressure is maintained in the saucepan or the bursting pressure is prevented from being reached by the safety valve responding .

Refillable printer cartridges are sometimes equipped with a spring-loaded ball valve that securely encloses the printer ink, but also allows refilling from the outside. The ball must be pushed back with a syringe.

Pustefix cylinder bellows for blowing away dust or inflating balloons have a valve with a loose steel ball about 9 mm in diameter near the outlet nozzle. In the blowing position, the ball is held by a diametrically running steel pin, when the handle and piston are withdrawn, the ball rests against the plastic (or formerly wood) sealing seat to avoid sucking in dust or sucking out the balloon. The smaller ball of a hand pump for modeling balloons also seals adequately under the higher pressure. In pumps that are operated by axial shaking, the inert centrifugal mass of the medium to be pumped as well as the steel balls are used.

Spring-loaded ball valves near the nozzles of car windshield washer systems prevent the wash water from sinking back into the line during breaks.

Simple small pumps and tube lifters for aquariums or diesel oil sometimes have spring-loaded ball valves.

Grease nipples on machines usually contain a small spring-loaded ball valve that opens when the pressure of the grease comes out of the press.

Some types of paint pens have a spring-loaded ball valve that, if necessary, has to be opened by pressing the nib particularly hard to allow the paint to flow in. In the rest position, the valve seals to prevent the solvent from evaporating.

One type of diving snorkel for children featured a lightweight table tennis ball in a guide housing which, when immersed, was pushed upward in a valve seat by buoyancy. Under inhalation negative pressure, the valve remained closed even when exposed to water, only light blowing (or at least depressurization) opened the ball valve again.

The principle of the ball valve is used in the historical ball closure bottle to keep a carbonated drink in a sealed manner until the bottle is opened. The ball valve, consisting of a glass ball and rubber ring in a groove in the neck, only remains closed due to the high internal pressure in the bottle (due to CO 2 ). Short ink cartridges for (vulgo :) fountain pens have a ball lock with a glass ball about 1 mm in diameter, which acts as a ball valve when refilling the Do-It-Yourself from an ink bottle.

In small animal watering can be found at the exit of one or two metal balls that own by gravity and hydrostatic pressure include the slightly narrowed opening of the water. If the pet presses against it with its tongue, water can seep from the container. Because of the dominant surface tension of the water with these dimensions, no seal is necessary. On the other hand, for the same reason, pushing the balls back is usually not enough for the water to flow out of the nozzle by itself. Rather, the balls press the water that has flowed back out of the opening as they roll back, and the meniscus is repeatedly disturbed by the contact with the tongue, which enables further flow .

Vent valve

In the case of valves for venting water pipes, a design with a ball floating in water is used. This closes the valve seat located above in the floated state. When air reaches the vent valve, the ball falls out of the valve seat because the air cannot carry the valve ball . The valve is open and the air escapes. The valve ball floats again in the incoming water and closes the valve seat.

Rigid Edwards prosthesis

One of the best-known examples of a ball valve is the Rigid Edwards prosthetic heart valve , but production was discontinued in 2003. With this type of prosthesis, the ball is held over the valve opening by a wire cage. The simplicity of the construction should be the basis for a long implantation period and the insensitivity of the ball valve to particles (here blood cells ) should minimize hemolysis of the blood flowing through it. However, advances in design and manufacturing have made it possible to achieve the mechanical reliability of double-wing valves that of the Starr-Edwards prostheses, while at the same time providing greater flow and less hemolysis.

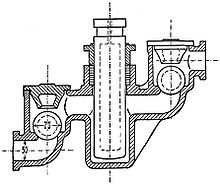

Pulsometer steam inlet valve

The central control valve in a pulsometer pump is designed as a ball: Depending on the position of the ball, the steam flows into one or the other of the pump chambers and seals the pump chamber that is not currently being perfused so that the negative pressure required for filling can build up there .

replacement

In some cases, ball valves have been replaced by round, 1.3–2 cm thick rubber flaps that cover the inflow opening over a large area and, when open, bend over a spherical shell-shaped valve catcher. The lower mass and overall depth of the valve are advantageous here. What is negative, however, is the restriction on the choice of material (rubber) and thus on the substances that can be conveyed (no acids and no alkalis) and temperature ranges. The valve seat is also covered over a large area.

literature

- Otto Lueger: Lexicon of all technology, entry: Pump valves , Volume 7. Deutsche Verlagsanstalt, Leipzig 1904–1920, p. 290.

- Meyers Großes Konversations-Lexikon, entry: Ventil , Volume 20. Bibliographisches Institut, Leipzig 1905–1909, p. 25.