Inert gas welding

The arc welding is a group of welding processes belong to a group of arc welding include (along with the manual metal arc welding ), which in turn for fusion welding counts. As with all fusion welding processes, the components to be connected are melted at the joints in order to create the connection after solidification . As with all arc processes, the heat source for melting is an electric arc that burns between the conductive workpiece and an electrode. A characteristic of gas- shielded welding is the use of shielding gases (usually argon or helium ), which shield both the electrode and the melt from the ambient air and thus protect against unwanted chemical reactions. In all processes, the electrode is located in the center of the torch, in which the supply of the protective gas is integrated. In some processes, the electrode melts and thus also functions as a filler material . In this case it consists of the same or similar material as the workpieces to be joined. This includes gas -shielded metal arc welding (MSG) with its two variants of metal inert gas welding (MIG) with inert gases, i.e. those that do not react with the melt, and metal active gas welding (MAG) with reactive gases, the desired chemical reactions cause. The electrode can also be non-consumable. The filler material is then fed in separately and held in the arc. These include tungsten inert gas welding (TIG) and the related plasma welding .

Metal arc welding

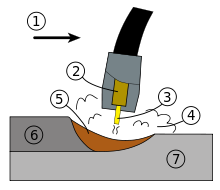

Semi-mechanical gas-shielded metal arc welding (MSG), optionally as MIG (metal welding with inert gases, EN ISO 4063: Process 131) or MAG welding (metal welding with active, i.e. reactive gases, EN ISO 4063: Process 135), is an arc welding process in which the melting welding wire is continuously tracked by a motor with variable speed.

The common welding wire diameters are between 0.8 and 1.2 mm (less often 1.6 mm). At the same time as the wire feed, the protective or mixed gas is fed to the welding point via a nozzle at approx. 10 l / min (rule of thumb: protective gas volume flow 10 l / min per mm of welding wire diameter). This gas protects the liquid metal under the arc from oxidation, which would weaken the weld seam.

variants

LIKE

In metal active gas welding (MAG) either pure CO 2 or a mixed gas consisting of argon and small proportions of CO 2 and O 2 (e.g. "Corgon") is used. Depending on their composition, the welding process (penetration, droplet size, spatter losses) can be actively influenced.

This gas is mainly used with simple or low-alloy steel such as structural steel .

MIG

In metal inert gas welding (MIG), argon is used as the noble gas , and more rarely the expensive noble gas helium .

The MIG process is preferred for non-ferrous metals (NF) and stainless steel .

Filler wire

Optionally, cored wires , also known as tubular wires, can be used for gas-shielded metal welding (with active gas welding EN ISO 4063: Process 136, with inert gas EN ISO 4063: Process 137) - with the advantage of being able to do without the shielding gas with a separate cylinder and fittings.

The inside of the wires is provided with a slag former and, if necessary, alloy additives. They serve the same purpose as the sheaths on a stick electrode. On the one hand the ingredients contribute to the sweat volume, on the other hand they form a slag on the weld bead and protect the seam from oxidation. The latter is particularly important when welding stainless steels, since oxidation, the " tarnishing " of the seam, must be prevented even after the torch has been continued and the shielding gas hood continued.

High-quality welding machines differ from cheap ones, among other things, in the possible duty cycle. The latter often require rest phases that are twice as long as the actual duty cycle ( ED ).

Arc types

Depending on the materials to be welded and their sheet metal or wall thickness, different types of arcs can be set by selecting suitable parameters. The short arc is used in the lower power range, in which short circuit and free-burning arc alternate. The spray arc is used in the upper performance range. The melting filler metal is melted short-circuit-free. A very focused, stable arc with a particularly high arc pressure can be generated by special regulation. There is an intermediate area between short-circuit and short-circuit-free material transition. One speaks of a transition arc . It should be avoided because of its stochastic character. In the case of a pulsed arc , a basic current is superimposed with increased current pulses. The material transfer can be controlled. The heat input into the workpiece and the electrode can be influenced by the alternating current arc, and oxides on the surface of aluminum and its alloys are broken up.

Gas-shielded metal arc welding with increased deposition rate

The welding speed and thus the productivity can be increased if the so-called deposition rate, i. H. the amount of melted material per unit of time is increased. Two approaches have been found to be effective for this:

- parallel use of several welding wires (multi-wire welding)

- Use of special shielding gas combinations, cored wires and welding parameters (variants of TIME welding)

Multi-wire welding

There are two types of procedure:

With the double wire method, two wire electrodes are fed through a common contact tube. Two arcs are created, which are generated by a power source. Therefore, they cannot be controlled independently from each other. Multi-wire processes are often used as submerged arc welding .

The tandem process is the further development of the two-wire process. In the tandem process, two electrically independent arcs burn in a shared weld pool. The high melting rate of two wires can be converted into welding speed or volume filling. The electrical separation of the wire electrodes allows different process combinations. On the one hand, the electrical parameters can be selected independently of one another; on the other hand, different wire diameters and materials can be used. This opens up new combination options and deposition rates of up to 25 kg / h.

Variants of TIME welding

By selecting suitable shielding gas combinations, cored wires and welding parameters, the deposition rate can be increased significantly without negatively affecting the weld seam quality. The MAG process can be based on a 4-component gas mixture (Ar, He, CO 2 , O 2 ) and a high wire feed speed (up to 50 m / min) with a longer free wire end (up to 35 mm) at a deposition rate of up to can be brought to 27 kg / h. On this basis, several process variants with the names TIME ( Transferred Ionized Molten Energy ), RapidProcessing, RapidArc, RapidMelt, LINFAST are on the market, for the implementation of which appropriate power sources and wire feeders have been developed. Further investigations into the influence of gas combinations on the deposition rate led to different variants for gas composition.

The TIME process can also be combined with multi-wire welding (TimeTwin welding process) with two power sources and separate welding potential for one of the two welding wires.

Gas-shielded metal arc welding with reduced heat input

Cold Metal Transfer - CMT

ColdArc method

The ColdArc process is a variant of the MIG / MAG process with the short arc , in which the material transition is achieved with less heat input into the base material by controlling the welding current. The basic idea is to reduce the current peak during the short-circuit when welding with the short arc and to support the re-melting of the wire by means of a melting current pulse. The current is then reduced to a very low level, thereby minimizing the energy input. The melting pulse creates a consistently large molten dome on the fed wire and enables extremely low currents to be used in the phases between the short circuits.

Tungsten inert gas welding (TIG)

Tungsten inert gas welding (TIG welding, USA: Tungsten Inert-Gaswelding (TIG) or Gas Tungsten Arc Welding (GTAW), EN ISO 4063: Process 141) is a welding process in which the electric arc between the workpiece and a Tungsten electrode burns. Because of the high melting point of tungsten, the electrode does not melt, unlike other arc processes. The filler metal is held in the arc in the form of wires or rods and thus melted. In addition, as in all arc processes, the arc melts the base material. So that the melt does not react with the ambient air, inert gases are used that are inert, i.e. do not enter into any chemical reactions with the materials involved. Often it is argon or helium. Particularly high seam quality can be achieved with TIG welding, but it is somewhat slower than the related metal inert gas welding (with melting wire electrode).

Orbital welding

Orbital welding is a fully mechanical inert gas welding process, TIG or MSG, in which the arc is mechanically guided 360 degrees around pipes or other round bodies without interruption. The orbital welding process is preferably used in pipeline construction, where consistently high seam quality must be achieved under controllable conditions. The main areas of application are pipeline construction as well as pipeline and apparatus construction in the food, chemical and pharmaceutical industries. All materials can be welded that can also be joined using the corresponding TIG or MSG processes.

Plasma welding

In plasma welding (plasma metal inert gas welding, EN ISO 4063: Process 15), a plasma is used as the heat source. Plasma is an electrically conductive gas that is heated to a high level by an arc. In the plasma torch, the plasma gas (argon) flowing through is ionized by high-frequency pulses and an auxiliary arc (pilot arc) ignited. This burns between the negatively polarized tungsten electrode and the anode designed as a nozzle and ionizes the gas column between the nozzle and the positive-polarized workpiece. A contactless ignition of the arc is possible. Gas mixtures of argon and hydrogen or argon and helium, which protect the melt from oxidation and stabilize the arc, are commonly used as plasma gas. The slight admixture of helium or hydrogen increases the penetration and thereby increases the welding speed. The narrowing of the plasma by the water-cooled copper nozzle to an almost cylindrical gas column results in a higher energy concentration than with TIG welding, which enables higher welding speeds. The distortion and the tension are therefore lower than with TIG welding. The process is also used in micro-welding technology due to the plasma arc, which burns stably even at the lowest current strengths (less than 1 A) and the insensitivity to changes in the distance between the nozzle and the workpiece. With the micro plasma welding process (welding current range 0.5–15 A) sheets of 0.1 mm can still be welded. Plasma taphole or keyhole welding is used from a sheet thickness of 3 mm and, depending on the material to be welded, can be used up to a thickness of 10 mm for single-layer welding without seam preparation. The main areas of application are container and apparatus construction, pipeline construction and space travel.

literature

- Specialist group for welding engineering training: joining technology welding technology. 6., revised. Edition. DVS Verlag, Düsseldorf 2004, ISBN 3-87155-786-2 .

- U. Dilthey, A. Brandenburg: Welding manufacturing processes. Volume 3: Design and strength of welded structures. 2nd Edition. Springer Verlag, 2001, ISBN 3-540-62661-1 .

- U. Dilthey (Ed.): Laser beam welding - processes, materials, production, testing. DVS-Verlag, Düsseldorf 2000, ISBN 3-87155-906-7 .

- K.-J. Matthes, E. Richter: Welding technology. Fachbuchverlag Leipzig in Carl Hanser Verlag, 2002, ISBN 3-446-40568-2 .

Web links

Individual evidence

- ↑ Birgit Awiszus: Basics of manufacturing technology. Hansa-Verlag, ISBN 978-3-446-41757-1 (section: Gas-shielded metal arc welding (MSG). Limited preview in the Google book search).

- ↑ Ulrich Dilthey: Welding Manufacturing Process 1: Welding and Cutting Technologies. Springer Verlag, 2006, ISBN 3-540-21673-1 (section: Metallschutzgasschweissen (MSG). Limited preview in the Google book search).

- ↑ Jens Meyer: Inert gas welding # 1 transformer with gas and wire, # 153 , In: Autoschraub.de, November 6, 2015

- ^ German Association for Welding and Related Processes V. (2000), DVS-Merkblatt 0915: Submerged-arc multi-wire welding

- ↑ JG Church, H. Imaizumi: TIME process. IIW / IIS Doc. XII-1199-90, 1990.

- ↑ St. Trube, E. Miklos ,: high-performance welding with the LlNFAST concept , Linde AG, REPORTS FROM TECHNOLOGY AND SCIENCE 77/1998

- ↑ M. Subana, J. Tusekb: Dependence of melting rate in MIG / MAG welding on the type of shielding gas used. In: Journal of Materials Processing Technology. 119, 2001, pp. 185-192.

- ↑ a b T. Höller: Basics of MIG / MAG welding , EWM AG , 2005

- ↑ Plasma welding: A productive high-performance welding process, PDF, summary of the process

- ↑ Gerd Witt among others: Pocket book of manufacturing technology. Carl Hanser Verlag, ISBN 3-446-22540-4 (section: plasma welding. Limited preview in the Google book search).