SŽD series ВМ20

| SŽD series ВМ20 (WM20) | |

|---|---|

|

BM 20

|

|

| Number: | 1 (2 sections) |

| Manufacturer: |

Kolomna plant Kharkov "Dynamo" electric motor plant |

| Year of construction (s): | 1934 |

| Retirement: | not specified |

| Axis formula : | 2'Do1 '+ 1''Do2' |

| Gauge : | 1520 mm |

| Length over buffers: | 27202 mm |

| Fixed wheelbase: | 4,500 mm |

| Total wheelbase: | 23,100 mm |

| Service mass: | 122.8 t total locomotive per section : 245.6 t |

| Friction mass: | 78.8 t total locomotive per section : 157.6 t |

| Wheel set mass : | 19.7 t |

| Top speed: | 70 km / h |

| Installed capacity: | 2 × 1200 hp |

| Starting tractive effort: | 21,000 kp |

| Driving wheel diameter: | 1,220 mm |

| Impeller diameter: | 900 mm |

| Motor type: | 6-cylinder four-stroke diesel engine |

| Motor type: | MAN 42-BMK-6 |

| Rated speed: | 450 rpm |

| Drive: | diesel-electric |

| Coupling type: | Screw coupling |

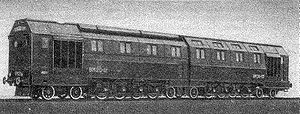

The locomotive of the class ВМ20 (German transcription WM20) of the Soviet Railways (SŽD) was a broad-gauge diesel locomotive of the first generation, which, simplified, consisted of two diesel locomotives of the series Э эл . The locomotive is considered to be the first two-section locomotive in the world and only one copy was built. It was named WM after Vyacheslav Mikhailovich Molotov .

history

Due to the sharp increase in freight train services at the beginning of the 1930s, the SŽD did not have enough powerful locomotives to haul the trains. It was therefore required to build a locomotive with top performance. It should have a total output of approx. 2000 hp and be manufactured in local factories. In terms of power and tractive power, it should be equivalent to the FD steam locomotive . For this reason, the Э эл 8 twin- engine locomotive was not an alternative because it was an import locomotive.

It was therefore decided to combine two locomotives of the Э эл series into a two-section locomotive in order to obtain the required performance. Each section had the wheel arrangement 2'Do 1 ' , and the entire locomotive therefore 2'Do 1' + 1'Do 2 ' . The draft design and the selection of the main parameters of the diesel locomotive were carried out by various design offices from the Kolomna plant . Both the possibility of using the locomotive as a single-section locomotive and as a two-section locomotive was considered. This resulted in five variants of the diesel locomotive with the following characteristics;

- Single section locomotive (wheel arrangement 2'Do 1 ' ) with a pulling force of 16,000 kp for light freight trains,

- Single section locomotive with a pulling force of 10,000 kp for light passenger trains,

- Two-section locomotive (axle formula 2'Do 1 '+ 1'Do 2' ) with a pulling force of 32,000 kp for heavy freight trains, '

- Two-section locomotive with a pulling force of 25,000 kp for medium-weight freight trains,

- Two-section locomotive with a pulling force of 20,000 kp for heavy passenger trains in difficult terrain.

The literature does not provide any information on missions and the duration of their use.

technology

The diesel locomotive had diesel-electric power transmission with four electric traction motors per section. The electrical scheme allowed both one section and the two sections to be regulated from one driver's cab. The diesel engine, traction generator, exciter and cooler were housed on the frame of each section. Each section had a driver's cab. The compressor for the compressed air system was located at the rear of the section. Both sections could be connected to each other automatically via an SA-3 central buffer coupling .

Originally, four electric traction motors with an output of 175 kW each were to be used for the locomotives. But it kept the manufacturer expedient instead the electric traction motors from the Э эл with an output of 140 kW to use. In the end, this resulted in an inadequate ratio of diesel and electric drive motors. To compensate for this inadequacy, the transmission ratio of the traction drive motors was changed, and at the same time the current for the drive motors was increased from 350 to 375 A. The traction electric motors were connected in parallel during normal operation , in the event of an accident they were connected in parallel - in series .