SLM Eb 3/5

| SLM Eb 3/5 | |

|---|---|

| Numbering: | no |

| Number: | 1 |

| Manufacturer: | SLM |

| Year of construction (s): | 1927 |

| Retirement: | 1940 |

| Type : | 1'C1 'h3 |

| Gauge : | 1435 mm ( standard gauge ) |

| Length over buffers: | 13,140 mm |

| Height: | 4280 mm |

| Width: | 2900 mm |

| Fixed wheelbase: | 6550 mm |

| Total wheelbase: | 9500 mm |

| Empty mass: | 62.8 t |

| Service mass: | 75.0 t |

| Friction mass: | 48 t |

| Wheel set mass : | 16 t |

| Indexed performance : | permanent: 730 kW short-term: 1100 kW |

| Coupling wheel diameter: | 1520 mm |

| Impeller diameter: | 850 mm |

| Control type : | camshaft |

| Number of cylinders: | 3 |

| Cylinder diameter: | 215 mm |

| Piston stroke: | 350 mm |

| Cylinder pressure: | 60 bar |

| Boiler : | Winterthur boiler |

| Boiler overpressure: | 60 atm |

| Grate area: | 1.33 m² |

| Radiant heating surface: | before 1930: 11.7 m³ after 1930: 14.3 m³ |

| Tubular heating surface: | 97 m² |

| Superheater area : | 20 m² |

| Water supply: | 6.2 m³ |

| Fuel supply: | 2.7 tons of coal |

| Rated speed: | 700 min -1 |

| Drive: | Three cylinders - steam engine with Blindwelle |

| Translation levels: | 1 (1: 2.5) |

| Control: | 6 speed steps forward and backward |

| Particularities: | High-pressure locomotive with a water-tube boiler |

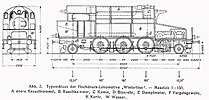

The Eb 3/5 was a high-pressure locomotive from the Swiss Locomotive and Machine Works (SLM) , which was built for test purposes.

history

In 1926 the SLM decided to build a high-pressure locomotive with a water-tube boiler on its own account. Before the locomotive was built, the boiler and steam engine were tested on a test bench for over a year. After the locomotive was completed in November 1927, the route tests began. The locomotive was then put into regular service by the Swiss Federal Railways (SBB), where it was compared with the B 3/4 . The results showed that the high pressure locomotive used 35 to 40% less coal and only half the water compared to the conventional locomotive. Test drives were also carried out in Austria and France.

The tests in France led to the order of the 232 P 1 by the French Northern Railway .

Although the runs were successful, the high-pressure locomotive was canceled in 1940. Due to the advanced electrification of the Swiss railways , there was no longer any need for steam locomotives.

technology

The steam locomotive was built for a maximum operating pressure of 60 atü . In front of the short and tall steam boiler was the fast-running three-cylinder steam engine with camshaft control , which reached 700 min −1 at 80 km / h . It drove the three drive axles via a gear train and coupling rods . The steam engine worked on the direct current principle . The filling could only be adjusted in 6 steps, which was not a disadvantage compared to a normal steam locomotive with stepless control during operation.

The SLM water tube boiler consisted of a fire box with lateral water tube walls and a water tube roof that ended in a large upper drum. Two smaller drums for holding the pipes were arranged along the bottom. After the regulator , the steam passed a superheater before reaching the steam engine. Exhaust steam and flue gas preheaters heated the feed water almost to boiler temperature, so that the scale was deposited in the preheaters and not in the difficult-to-clean water-tube boiler.

Conversions

The combustion air preheaters were removed after a short time. They could only recover a little heat and required maintenance that was not justified for their usefulness. After the test drives in France, the continuous output of the boiler was increased in 1930 by increasing the radiant heating surface from 11.7 m³ by 20% to 14.3 m³ by installing additional water pipes. The flue gas flow in the feedwater preheater has also been improved.

literature

-

Jakob Buchli : “Winterthur” high-pressure locomotive for 60 at boiler pressure .

Schweizerische Bauzeitung, Volume 91 (1928), Issue 22 (Part 1) (E-Periodica, PDF 3.0 MB)

Schweizerische Bauzeitung, Volume 91 (1928), Issue 23 (Part 2) (E-Periodica, PDF 3.2 MB) - H. Nyffenegger ,: The 60 at high pressure locomotive Winterthur . In: Schweizerische Bauzeitung . tape 97 , no. 24 , June 13, 1931, doi : 10.5169 / seals-44701 .

- Wolfgang Stoffels: Locomotive construction and steam technology: Tests and results with high pressure steam locomotives, steam engine locomotives, steam turbine locomotives . Springer-Verlag, 2013, ISBN 978-3-0348-5877-9 , 3.23.6 The Locomotive of the Swiss Locomotive and Machine Factory, Winterthur, p. 45-50 ( google.com ).