Woodruff key

|

|

DIN 6888 |

|---|---|

| Area | Machine elements |

| title | Driver connections without tightening, disc springs, dimensions and application |

| Brief description: | Disc springs |

| Latest edition | 1956-08 |

| ISO | - |

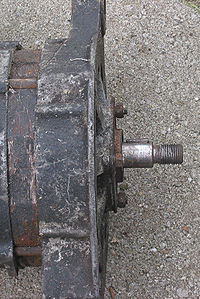

A disc spring is a machine element of the machine construction and is similar to the key to the realization of a shaft-hub connection used. The form-fit connection technology is used to transmit torque, for example from the drive shaft to the gear . In the past, disc springs were also known as Woodruff wedges .

construction

The woodruff key is a solid, semi-disk-shaped metal part, which is inserted into a correspondingly milled groove in the mostly conical shaft and protrudes from it. The shaft groove is provided with a disc milling cutter machined as semi-circular groove in the shaft and the semicircular disk as a wedge inserted.

The associated, mostly conical hub is provided with a continuous and broached groove and is pushed on for assembly as a conical seat according to DIN standard DIN 228 , DIN 254 , 1448, or 1449. The woodruff key has a form fit on its flanks. It acts as a driver and transfers the torque of the shaft to the component to be driven (in the case of a drive shaft) or the torque of the driving component to the shaft to be driven (in the case of an output shaft). In the axial direction, the wheel is secured against displacement on the mostly conical shaft by fixing it with a locknut .

Dimensioning

The size of the woodruff spring results from

- from the shaft diameter (for example, the disc spring cross-section (width × height) 10 × 16 mm is provided for the shaft diameter 35 mm) and

- The torque to be transmitted, which determines the length of the feather key (calculation based on the surface pressure between the hub and feather key).

standard

Woodruff springs according to the DIN standard are standardized according to their shape and dimensions in DIN 6888. This standard specifies u. a. also states that a fit with the tolerance field P9 for a tight fit or N9 for a light fit according to the standard shaft fit system according to DIN 7155 is used to tolerate the groove width . The woodruff width thus corresponds to a standard shaft with tolerance field h9 (lower dimension = 0). The pane height is designed with a tolerance field of h12 . DIN 6892 specifies the design and calculation bases for feather key connections.

material

The material used is usually half-round steel made of E335 (previously St 60-2).

Advantages / disadvantages and alternatives

- Advantages of a woodruff connection:

- inexpensive

- very easy to assemble / disassemble

- With conical shafts only one-sided protection against axial displacement is necessary

- Disadvantages of a woodruff connection:

- Notch effect on the shaft

- unsuitable when changing load direction

- transmittable torque relatively low

- The shaft is severely weakened by the necessary, deeper groove

- Alternatives to the woodruff connection: