Smart & Kleedern

Bridles, Smarten (Schmarten), Marlen and Kleedern (Kleeden) are the nautical names that are used for the work process to protect the ropes or wire ropes.

In the seafaring is rope , usually standing rigging , ropes , rigging and much more. to protect against abrasion ( Schamfilung ) Rott (natural fibers) or corrosion (Drahttauwerk) with Hüsing or Schiemannsgarn gekleedert ( "cases").

Snaffles

In the first step, the keepers, ie the "grooves" in the rope, are filled with strands of waste rope in order to obtain a uniformly smooth surface. This work step is called "bridle".

Smart

The “Schmartung”, a winding of canvas canvas , mostly cut as diagonal strips, takes place over the separation . In many cases, the scarring on wire rope was additionally coated with a protective coating of red lead .

Marlen

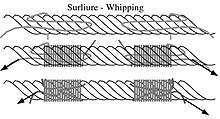

The tightly wrapped canvas strip is fixed with a thin ribbon and a Marlschlag binding. This work is referred to as "Marlen".

Clover

The “clover” is then wound over the pecking. After each work step , the rope is usually preserved with refreshment , a viscous mixture based on wood tar . At the beginning of the clover, the yarn is laid parallel to the rope and continuously wound over. If the yarn is not enough for the whole dressing, the end is also tied in parallel with the new beginning. With spliced eyes, start from the eye.

- Parting and pecking always follow the “blow” of the rope, the cloing against.

"Trens' and Schmarte like twisted, the other way around is with Kleed"

With stronger cordage, the clover club is used to ensure tight and tight wrapping. This can be compared with the winding device and the windings on a bowstring .

The picture on the right shows the final sequence of a cloak: At the end of the cloak you create a bay and wind it back through the bay in the same direction of rotation (at twice the distance between the last turns to be wound). The end of the Schiemanns yarn is placed over the finished windings. The remaining windings are then wound over the end with the bay under constant tension. Ultimately, the bay is brought close and excess yarn is cut off close to the windings so that the end remains “invisible”.

A perfectly tightly wrapped clover can be recognized by the partially exuding root tar .

literature

- Sondheim; Knots, splicing, rigging , Klasing + Co, 1975 ISBN 3-87412-009-0 .

- Katrin Radestock, Viking Ziegler: The Little Boatswain . Self-published, 18.5 Refreshment and tar - running and standing goods, p. 33 ( online (PDF; 12.2 MB) [accessed on May 1, 2012]).

- Clifford W. Ashley: The Ashley Book of Knots . Over 3800 knots. How they look like. What they are used for. How they are made. Special edition. Edition Maritim, Hamburg 2005, ISBN 3-89225-527-X . (From Chapter 40 Practical Marlingspike Seamanship)

See also

Individual evidence

- ↑ ABOK # 3336- # 3338

- ↑ ABoK # 1487, # 3339

- ↑ ABoK # 3340, (# 1486 another variant)

- ↑ ABoK # 3344 - # 3351

- ↑ Picture of a clover , clover combined with a spool of thread

- ↑ (image) Manufacture of centipedes (millipedes)