Electrical sheet

|

|

DIN EN 10106 |

|---|---|

| Area | Semi-finished steel products |

| title | Cold-rolled non-grain-oriented electrical sheet and strip in the final annealed condition |

| Latest edition | 2007-11 |

| ISO |

|

|

DIN EN 10107 |

|---|---|

| Area | Semi-finished steel products |

| title | Grain-oriented electrical steel sheet and strip in the final annealed condition |

| Latest edition | 2005-10 |

| ISO |

Electrical steel is the most important soft magnetic material for magnetic cores . According to its characteristics, it is divided into:

- Grain-oriented materials, also called transformer or core sheet , depending on the intended use , and

- non-grain-oriented materials, also called dynamo or motor sheet metal .

Electrical sheet and strip in the narrower sense of cold rolled strip of iron - silicon - alloys , in addition, the resulting cut or punched sheet metal lamellae , which are used for the manufacture of magnetic circuits for electrical machines , that is of iron cores for:

- Dynamos

- Electric motors

- Transformers

- relay

- Contactors

- Choke coils

- Ignition coils

- Electric meters and

- controllable deflection magnet .

The magnetic, physical and other requirements for the material are described in the standards:

- EN 10106: "Cold-rolled non-grain-oriented electrical steel sheet and strip in the final annealed condition" and

- EN 10107: "Grain-oriented electrical steel sheet and strip in the final annealed condition".

function

Iron cores made of solid material are hardly usable in machines and transformers, because eddy currents arise under the influence of variable magnetic fields . Instead of transmitting electrical power, the core becomes hot due to eddy currents with increasing frequency. In order to avoid this, iron cores for electrical machines are designed exclusively as laminated and insulated sheets in packs or as wound cut strip cores . A corresponding design is also referred to as laminated .

Soft magnetic materials form a magnet under the influence of a magnetic field and, when the field is switched off, largely return to the non-magnetic state. Simple dynamo sheet IV could be used magnetically with a maximum of 1.2 Tesla (= 12,000 Gauss ). Advanced iron-silicon alloys enable flux densities of up to around 1.75 T.

Embodiments

Standard cores are made from punched individual sheets, which were previously insulated by paper layers glued on one side, and in more modern form by chemically applied phosphating layers. The sheet thickness for normal applications is often 0.5 mm. For electrical transmitters of higher frequencies or particularly low-loss devices, thinner sheets with a thickness of 0.35 mm are used. Cut tape and toroidal cores are often wound from even thinner and also insulated tapes.

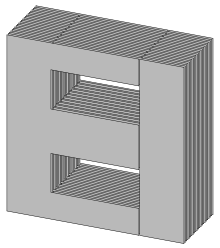

A classic and widely used sheet metal cut especially for transformers is the EI core. With every punching process, two E and two I fall out and there is almost no waste. This is why this cut is also known as the waste-free EI cut. The sheets can be layered on one side or alternately. For mains transformers and push-pull transformers, the sheets are layered alternately, i.e. That is, E and I are alternately pushed into the bobbin from the left and then from the right . This minimizes the air gap. If layering is only carried out on one side, a defined air gap can be built in, which is necessary for line filter chokes and for single-ended transformers.

Circular sheet metal cuts for motors and generators usually have cutouts which, when stacked on top of one another , produce the grooves for the winding with insulated copper wire for the coils , as well as the central circular cutout for the axle shaft.

Baking sheet

The sheets can be provided with a special coating (baking varnish) so that sheet stacks can later be baked together by heating or solvents. The purpose is better mechanical strength and, if necessary, a reduction in noise generated by the vibration caused by magnetostriction . This method is often used as an alternative to complete soaking or potting.

material

Electrical steel sheets mostly consist of an iron-silicon alloy (silicon content approx. 3%). While the non-grain-oriented material has as isotropic magnetic properties as possible in the plane of the sheet and is therefore preferably used for rotating machines, grain orientation ( texture ) is created in the grain-oriented material through several successive rolling and annealing treatments . This targeted anisotropy in the material reduces the magnetic reversal losses and the relative permeability increases with the corresponding direction of magnetization . With this textured material, compared to non-grain-oriented materials, it is therefore possible to manufacture transformers which have a smaller overall size and are more efficient.

The following table shows the ratios for M and MD cores based on the core size M 102 B / MD 102 B and 50 Hz. A SM cut ribbon core is also listed for comparison. The bobbin type is the same for all core sizes.

| Name of the core material | Losses per kilogram of iron (at f = 50 Hz, B pk = 1.5T) |

Sheet thickness | Maximum induction | transferable power (core cut) |

|---|---|---|---|---|

| M 530-50 A | 5.30 W | 0.50 mm | 1.31 T | 198 VA (M 102 B) |

| M 400-50 A | 4.00 W | 0.50 mm | 1.39 T | 215 VA (M 102 B) |

| M 330-35 A | 3.30 W | 0.35 mm | 1.41 T | 224 VA (M 102 B) |

| M 111-35 N | 1.11 W | 0.35 mm | 1.64 T | 271 VA (M 102 B) |

| M 111-35 N | 1.11 W | 0.35 mm | 1.65 T | 320 VA (MD 102 B) |

| TRAFOPERM | 1.11 W | 0.30 mm | 1.78 T | 300 VA (SM 102 B) |

literature

- Hans Fischer: Materials in electrical engineering. 2nd edition, Carl Hanser Verlag, Munich Vienna, 1982 ISBN 3-446-13553-7

- Günter Springer: Expertise in electrical engineering. 18th edition, Verlag Europa-Lehrmittel, Wuppertal, 1989, ISBN 3-8085-3018-9

Web links

- Detailed information sheet on electrical steel and sheet metal as a PDF file (900 kB) from https://www.stahl-online.de

- Table of contents of DIN EN 10106: 2007-11 at Beuth-Verlag

- Table of contents of DIN EN 10107: 2005-10 at Beuth-Verlag

Individual evidence

- ↑ https://www.blechrohreprofile.de/blechumformtechnik-fachartikel/alternativen-zum-elektroblech_28719_de/ Vacuumschmelze Hanau: Alternatives to electrical sheet metal in UMFORMtechnik, October 2014

- ↑ Gerhard Haas : Everything you always wanted to know about transformers, filter chokes and NF transformers