Waste water heat recovery

Waste water heat recovery ( AWRG ) or waste water heat recovery (AWN) is the heat recovery of the waste heat contained in the waste water . Wastewater has an average temperature of 10 to 12 ° C in winter and between 17 and 20 ° C in summer. This temperature stands for heat or thermal energy that can be extracted from the wastewater. Wastewater can not only be used for heating in winter , but also for cooling in summer. H. Buildings can be air-conditioned. With the help of a heat exchanger and a heat pump , this energy can be easily harnessed - particularly climate-friendly and increasingly more economical.

Wastewater heat can either be obtained from the sewer system , a building or from a sewage treatment plant. In Germany, the energy contained in wastewater can cover 14 percent of the heating requirement in the building sector. There is a lot of wastewater where there are people and industry. In other words, exactly where there is a high demand for energy. Source (sewage) and demand (energy) go very well together, especially in cities and metropolitan areas. The basic idea: The residual heat or residual energy from the wastewater is free. It can be reused, reducing the need for and costs for other fuels or energy sources . The cheaper the system for recovering this residual energy, the faster the investment in the system will pay off. The use of waste water heat could contribute to decarbonization and the energy transition in the heating market in the future .

In Germany, waste water heat recovery systems have been used sporadically since the 1920s. In the last few years, around 100 larger plants for generating energy from wastewater have been implemented in Europe, the largest with 2.1 MW extraction capacity in the Neckarpark in Stuttgart. However, this form of energy generation has not yet achieved strong market penetration, as buildings have so far primarily been heated with natural gas or crude oil. With the energy transition and climate protection , which also reach the heat supply, the market position of wastewater heat utilization is currently changing and there is greater demand.

Waste water heat from the public sewer system

Working principle

Standardized heat exchangers made of stainless steel can be installed along the bottom of a sewer without great effort in the case of new sewer construction, sewer renovation or existing sewers. The waste water flows over and, if necessary, under the heat exchangers. A water cycle is integrated into them, which is colder than the wastewater. The wastewater flowing through the heat exchanger heats this water cycle, which then flows to the building to be heated. There the warm water, which has absorbed energy from the sewer and brought it to the house, is made usable with a heat pump. Concrete elements with integrated heat exchangers are an alternative to the classic duct heat exchangers. These are mainly suitable for new sewer construction. To cool the building, the process can also be reversed in the summer months. In this case, the waste water is used to remove the excess heat extracted from the building.

The wastewater in the sewer, which has an average temperature of 15 ° C, is cooled by the extraction of heat, but the sewage temperature recovers after a few meters through new inflows into the sewer and the ambient heat from the earth. Depending on local regulations, wastewater may be cooled down to 5 ° C. A continuous flow of wastewater is a prerequisite for reliable operation. The object to be supplied should therefore be within reach of a sewer system with a sufficiently strong flow. Suitable locations are in cities and municipalities with more than 5,000 inhabitants. Heat exchangers (plates / tube bundles / gutters) can, however , become clogged or contaminated by solids ( faeces , kitchen waste, diapers ) and cooling fats. They must therefore be designed in such a way that no so-called biofilms or sieve membranes develop on their surface or that they have to be cleaned a maximum of once a year. The invention of the anti-fouling system has resulted in the formation of biofilms being almost entirely prevented.

The energy obtained in the public sewer or in a house can only be used again immediately in special cases, for example in the vicinity of laundries. Normally, the energy is brought to the flow temperatures of 30 to 70 ° C required for heating the building using a heat pump . The heat pumps can achieve performance figures up to JAZ 4 or 5 ( annual performance factor ) at condensation temperatures of 60 ° C. (Compared to other heat pump systems, however, a comprehensive analysis should assume a measured JAZ at the same condensation temperature. A comparison with the COP only takes one operating point into account and does not necessarily correspond to the real operating conditions.)

scope of application

AWRG is suitable for heating and cooling small and large buildings. If the amount of energy that is withdrawn from the duct is large, systems remain economical even if the duct is far away from the building to be supplied. If the amount of energy is small, then a greater distance between the sewer and the property makes the system uneconomical. The system sizes are between 20 kW and several MW. As a rule, a minimum size of around 20 residential units is required for a building. In practice, building heating systems are usually designed as a bivalent system, so that waste water heat z. B. covers the base load (70 to 80% of the heating requirement) and conventional heating is provided as a supplement for the remaining peak load. The use of AWRG in single-family houses and small multi-family houses is currently not usually economical, as the technical effort for the entire system is disproportionately high for small installations.

It is also possible to feed into heating networks , especially in modern low-temperature systems such as fourth-generation district heating networks .

Project realization

AWN from public channels is a decentralized energy generation approach. It must be checked in each individual case whether a suitable duct with the corresponding energy potential exists for a building to be supplied with heating or cooling. This sewer must not be too far away from the property, otherwise the connecting line to be laid between sewer and house would be too expensive. The so-called development distances, d. H. the distance between the sewer and the property should be short with small amounts of energy, but with large amounts of energy it can also be several hundred meters without jeopardizing the profitability of the system.

Use of the sewer system requires the operator's approval, usually the municipality. Obtaining this presupposes that it can be proven that the operation of the heat exchangers does not cause any restrictions for the sewer network management. Some sewer network operators are already marketing their energy potential by publicly making energy maps available that visualize the energy potential. This offers a considerable acceleration in project development or site assessment. Some municipalities and public utilities also implement AWN projects as energy contractors .

economics

Energy generation from wastewater is already economical today at suitable locations. The energy source wastewater offers a constantly high temperature level even in winter, so that AWN systems offer high economic efficiency and are used in cities and metropolitan areas in particular. In summer, the same system can also be used for cooling, which can significantly increase profitability. Project development, on the other hand, is different in difficulty and cost. Not all sewer network operators actively develop the energetic potential of their sewers. As a result, the acquisition of information on suitable channels, i.e. the location check, can be time-consuming and therefore costly.

Waste water heat directly in the building

Heat recovery in the building means that, for example, energy is recovered from the used bath or shower water behind the drain of a shower or bathtub. It is also possible that heat is recovered from the main sewer of a house. This energy is then made usable again for the same building. In order to fully recover the thermal energy of the wastewater or to make it usable for heating purposes, on the one hand the residual energy must be collected, e.g. B. with a heat exchanger, on the other hand, it must then be brought to the temperature level that is needed in the property for heating or hot water supply with a heat pump.

The energy extracted from the wastewater of a residential building can only cover part of the energy required for heating and hot water preparation in the same building. However, it is possible with simple means to withdraw around half of the maximum amount of energy that can be obtained from the wastewater if one restricts oneself to preheating the fresh water.

Down pipe heat exchanger

A down pipe heat exchanger has a similar structure to a falling film evaporator and in the simplest case consists of a double-walled tube. For better control of the external mass flow, however, the inner (sewage) pipe is often wrapped in a spiral by a much thinner pipe instead of being surrounded by a simple jacket pipe. Such heat exchangers have been in use in North America for a long time (see en: Water heat recycling ). In contrast to the methods mentioned above, this method can also be used economically in private households and even for partial recovery of the amount of heat contained in the waste water of a single shower, since the heat exchangers are available at prices below € 1000 and the installation can be done within 2 to 10 years amortized.

Working principle

When water flows through a vertical pipe, it spreads on the outer wall and forms a film there called a “falling film”. Depending on the diameter of the pipe, a relatively short pipe section is sufficient to generate the amount of heat that can be transferred. The draining wastewater usually has a temperature between 20 and 40˚C while the incoming cold water has an average of 10˚C. While the wastewater cools down in the heat exchanger, the incoming cold water is warmed up by around 12 to 14 Kelvin. The energy consumption for hot water preparation can be reduced by up to 35%. Every time warm water is drawn from the tap in the household, a corresponding amount flows into the water heater . However, since the time coincidence of the waste water flow with the subsequent flow of cold fresh water in the heat exchanger is usually only guaranteed in the shower, this must be taken into account when positioning the heat exchanger.

advantages

To operate a downpipe heat exchanger, neither a special course of the sewage pipes, nor the installation of a filter or regular maintenance is necessary. The wastewater is not diverted, stored or treated and no auxiliary energy is required. These devices are therefore also suitable in smaller residential buildings and can be retrofitted when renovating buildings.

Shower water heat exchanger

In contrast to most other drainage objects, the cold water inflow and the outflow of heated sewage usually take place at the same time in the shower. It is therefore advisable to install small, decentralized heat exchangers directly on the shower water drain. Downpipes DN 50 and shower channels with integrated heat exchangers, cylindrical heat exchangers for use in central floor drains of collective showers and shower trays with built-in heat exchangers for subsequent installation are available.

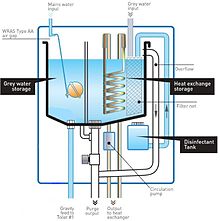

Gray water heat exchanger

If a storage tank is installed to reuse the gray water that occurs in the building , the heat exchanger can advantageously be installed in this tank to extract the thermal energy it contains. Compared to the downpipe heat exchanger, the energy of the warm water flowing from washing machines and dishwashers, wash basins and bathtubs can be recovered.

Waste water heat directly from the building

If the wastewater is collected centrally in a shaft (usually located outside the building envelope), the thermal energy contained can be obtained by an integrated heat exchanger. Daily fluctuations in the amount of wastewater are buffered by the intermediate storage. The system can therefore also be used for properties from around 25 residential units . Here, too, the heat exchanger and heat pump are connected to one another via a brine circuit. The distance between the building envelope and the shaft is relatively short and the losses to the environment are minimal. The average measured temperatures can thus be around ~ 23 ° C. Compared to the sewer system, only the waste heat that comes from the property itself can be used here. In order to be able to use a sufficient volume of wastewater, this system is suitable for hotels , hospitals , homes, wellness / baths and sports facilities as well as industrial companies with process waste heat . With the help of heat pumps, the hot water requirement can be completely covered in individual cases. The filter integrated in the shaft is either cleaned manually or backwashed automatically, depending on the system. Frequently, an additional, comprehensive cleaning of the shaft is necessary every 3–4 years. If necessary, this can be done through service openings from the outside.

Perspective and potential of waste water heat

Although not yet very widespread in German-speaking countries, the use of waste water heat can improve the energy balance of a property and reduce operating costs. In particular with medium-sized and larger buildings as well as with objects to be air-conditioned in summer, there are often short economic amortization times of less than 5 years compared to other alternative forms of energy. Wastewater heat recovery with a downpipe heat exchanger can also be economical under certain framework conditions and may pay for itself more quickly than other energy-saving measures.

With a view to the energy transition in the heating market and efforts to achieve more climate protection in the heating market, wastewater heat could play a significant role in the future.

Web links

- Brochure "Heating and cooling with wastewater - guide for building owners and municipalities" ( Memento from August 27, 2006 in the Internet Archive ) (PDF file; 886 kB)

- Brochure "Heat utilization from wastewater - guidelines for owners, operators and planners of wastewater treatment plants and sewer systems ( Memento from September 28, 2007 in the Internet Archive ) (PDF file; 4.2 MB)

- Energy from wastewater; Training documents - FEKA system (PDF file; 987 kB)

- AquaReEnergieFunnel

- Online calculator for the amortization calculation of downpipe heat exchangers of the Center for Energy Advancement through Technological Innovation (CEATI), Montreal, Canada

- AWNA calculator from Blue Synergy GmbH for calculating the economic amortization period of waste water heat recovery systems for installation in sewers ( Memento from August 17, 2014 in the Internet Archive )

Individual evidence

- ↑ energate messenger: Study confirms wastewater has high heat potential. In: www.energate-messenger.de. Energate, December 7, 2017, accessed April 25, 2018 .

- ↑ Bergmann, Tobias and Wannke, Michael: High-performance heat exchangers for using energy from wastewater. In BBR - specialist magazine for pipeline construction, well construction and geothermal energy 12/2012, pp. 26–31.

- ↑ Stuttgarter Zeitung: Start of construction for further quarters on the freight yard area. In: www.stuttgarter-zeitung.de. Stuttgarter Zeitung, March 15, 2018, accessed on April 25, 2018 .

- ↑ Abdur Rehman Mazhar et al .: A Key Review of Non-Industrial Greywater Heat Harnessing . In: Energies . tape 11 , 2018, p. 386 , doi : 10.3390 / en11020386 .

- ↑ Schwäbische Zeitung: Wastewater heat should provide additional energy in Wangen. (No longer available online.) In: www.schwaebische.de. Schwäbische Zeitung, March 15, 2018, formerly in the original ; accessed on April 25, 2018 . ( Page no longer available , search in web archives ) Info: The link was automatically marked as defective. Please check the link according to the instructions and then remove this notice.

- ↑ StEB Cologne: Potential map for the use of waste water heat. (PDF) www.steb-koeln.de, May 2, 2017, accessed April 25, 2018 .

- ↑ Information from Natural Resources Canada, Canadian Center for Housing Technology and the US Department of Energy

- ↑ Why Water Cycles - Water Cycles DWHR. Retrieved May 22, 2019 .

- ^ Drain-water heat recovery . Eco Home Tips. Archived from the original on January 17, 2012. Retrieved on February 3, 2012.

- ↑ ECOshower - heat recovery from shower water. Retrieved on May 22, 2019 (German).

- ↑ See the calculation result of the AWNA calculator: On the basis of the preset standard values, which correspond to a typical installation configuration, the payback period is 3-5 years. Assuming a lower biofilm load (20%) results in an amortization period in the range of 2-4 years. The calculator also does not take into account a potential use for cooling purposes, which would obviously further improve the amortization rate.

- ↑ See calculation result for the "default" setting of the CEATI computer (4 showers / day, 7 minutes each, 9.5 l / min), but at € 0.64 / m³: Under these general conditions, the downpipe heat exchanger pays for itself after about 3 , 5 years. The situation is different with a shower per day with 5 minutes and 6.5 l / min each: With saved € 22 / a and acquisition and assembly costs of over € 300, the payback period is more than 13 years.