Winding

A winding is a winding of a material around an axis in the solid aggregate state. It usually serves as part of a higher-level unit or facility. Typical applications of windings include securing two parts together, fitting an undersized pin into a bore, or accommodating a flexible, elongated object in a small space. Multi-layer windings consist of concentric coils that are superimposed by changing the direction of winding. A strapless winding is also known as unsupported or coreless. The term winding technology describes all technical processes for the production of windings. Windings can be made by hand or with winding machines. Windings are one of the oldest inventions of mankind.

production

In production (manufacture and / or further processing), the winding of flat strips (foils, paper) or filaments (tapes, threads, wires) is the most efficient method of storing the wound material in the smallest of spaces for storage or transport. The windings are set relatively loosely, since the winding material is to be unwound again at a later point in time. In addition, the material properties of the wound material should not change significantly in the wound state as a rule.

weapons

Spearheads and arrowheads made of bone, stone or metal are, depending on the construction of the shaft and the point, secured with a winding against falling out or lateral dislocation after being inserted into the shaft, so that the energy transferred to the shaft is transferred as completely as possible to the target via the point becomes. For this purpose, very tight windings are used, which are often additionally secured against unintentional unwinding with sticky substances. The fletching on arrows is still often fastened with windings.

Woodwind instruments

With woodwind instruments , several cylindrical tubes are often put together to form the actual instrument. The holes for the corresponding pins of the parts to be inserted are oversized, which results in a clearance fit . For a tight fit of the pin in the bore, a thread winding is applied to the pin. On the one hand, the winding must ensure a secure fit in the bore, but on the other hand, it must not be so thick that the part inserted in the bore can only be removed from the bore with great effort or even with the use of tools. Windings on parts that are used as tuning slide must also enable it to be operated effortlessly, but on the other hand prevent the part from being moved unintentionally due to even small forces.

A winding that only fully fulfills its function in the presence of moisture is referred to as a wet-tight winding . It usually consists of a thicker, swellable thread, often made of hemp . This type of winding requires a constant supply of moisture to maintain its function. Drying out such a winding leads to its shrinking and thus to leaks. The wet-sealing winding is therefore mostly only used in hand-blown instruments with a high air throughput and there only in places where the supplied air constantly flows. While playing, this type of winding absorbs moisture from the breathing air flowing through the instrument. Before the start of the game, it is often additionally moistened in order to work at the start of the game. Wet sealing windings hardly need any maintenance, but have to be renewed relatively frequently, since the thread gradually changes its properties disadvantageously due to the constant change between wet and dry state, which ultimately leads to permanent leaks. A typical instrument that mostly uses wet sealing windings is the Great Highland Bagpipe .

A winding that fulfills its function regardless of the presence of moisture is called a dry-sealing winding . It usually consists of a thinner thread, often made of cotton . The thread is usually treated with moisture-repellent substances before winding. A traditional method is to pull the thread through maximally lukewarm beeswax immediately before winding . The dry-sealing winding can be used on hand-blown and bellows-blown instruments regardless of their air flow. It requires more maintenance than a wet-sealing winding. So it has to be re-impregnated regularly. A traditional method is the application of deer tallow .

Windings on woodwind instruments are wearing parts. As a result of the pressure acting on them when the connection is inserted, the windings become increasingly compact, which leads to a corresponding shrinkage and thus ultimately to leaks. If the winding is still firmly seated on its peg, this loss can be compensated for by rewinding another thread. If the winding on the pin is loose or can even be turned on it, it must be completely replaced. Maintaining, reworking and replacing windings is often done by the musician himself. In order to improve the adhesion of the winding to the pin, the surface of the pin in the area of the winding is often roughened in some way. A common practice is to make grooves of shallow depth in this area.

On double reeds , the two tongues are connected to the carrier pipe with a winding. This winding is made very tight and serves not only to connect the parts but also to fine tune the reed. Another winding can be located at the lower end of the support tube in order to fit it into the reed holder. On many instruments, the tongue is attached to the tied-up single reeds with a winding on the throat. This winding is made very tight and serves not only to connect the parts but also to fine tune the reed. Another winding can be located at the lower end of the throat to fit it into the reed seat. Windings on reeds are usually dry-sealing windings that are made from moisture-repellent threads and are very low-maintenance. The windings are usually designed so that their service life exceeds that of the tongue (s). Only the winding for fitting into the reed holder is in a few cases designed as a wet-sealing winding.

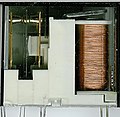

Electrical engineering

In electrical engineering , the term winding is used for a coil made from a conductor. Windings are also a basic element of transformers , relays , contactors , motors and generators , which are used to generate or transmit magnetic fields based on electrical conductors . The winding wires are insulated so that the current only flows through the conductors and not across them. In motors and generators in particular, very complex windings are often found. In electrical engineering, the number of turns as well as the conductor cross-section and the dielectric strength of the insulation of the winding wires are essential parameters of the windings.

In electrical engineering, windings can also be applied directly to various flat materials (e.g. solid printed circuit board materials or flexible film materials) using etching or adhesive processes. These then usually have a spiral-like shape and can be designed as a single or multilayer.

The wound coil is one of the oldest electrotechnical components.

literature

- Woodwind instruments:

- Hofmann, Michael: Sackpfeifers manual . Publishers of the Minstrels , ISBN 3-927240-02-8