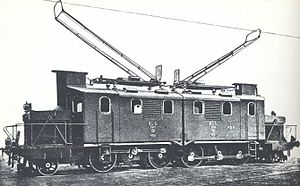

BLS Fb 2x2 / 3

| Fb 2x2 / 3 | |

|---|---|

| Numbering: | 101 |

| Number: | 1 |

| Manufacturer: | AEG, Krauss |

| Year of construction (s): | 1909 |

| Retirement: | (1912) |

| Axis formula : | 1'B-B1 ' |

| Length over buffers: | 15760 mm |

| Total wheelbase: | 12050 mm |

| Service mass: | 96 t |

| Friction mass: | 68 t |

| Top speed: | 75 km / h |

| Starting tractive effort: | 8000 kg |

| Driving wheel diameter: | 1270 mm |

| Impeller diameter front: | 900 mm |

| Power system : | 15,000 V 15 Hz (16 2/3) |

| Brake: | Westinghouse |

| Train brake: | Westinghouse |

The Fb 2 × 2/3 was AEG's electric test locomotive for the BLS test route Spiez - Frutigen .

General

In order to clarify which type of locomotive should be procured for the Lötschbergbahn , the management decided in the winter of 1907/08 to electrify the Spiez - Frutigen section (formerly Spiez-Frutigen-Bahn ) immediately in order to gain experience when the mountain line was completed of electric traction. In the spring of 1908, based on the tenders received, it was decided to electrify the line with single-phase alternating current of 15,000 volts and 15 periods / second (Hertz). The system was later adapted to this frequency when the administrations of Prussia, Bavaria and Baden decided to use 16 2/3 Hz.

The systems were designed in such a way that no reconstruction work had to be carried out as soon as the line could be used continuously to Brig . As a result, they were actually oversized for the trial operation.

The supply of electrical energy was transferred to the Bernese power plants . They expanded their existing plant in Spiez and built the Kandergrund power plant with a view to the opening of the mountain route , which was completed in 1911.

A catenary with chain suspension was chosen.

In addition to the AEG machine described, there was also a type F 2x3 / 3 locomotive from Maschinenfabrik Oerlikon and three railcars from Elektrischen Bahn Zürich, a joint venture between Maschinenfabrik Oerlikon and Siemens-Schuckert-Werke in cooperation with the Schlieren wagon factory , at the test site Ce 2/4 involved.

Technical

The locomotive consisted of two closely coupled locomotive halves, each with two driving and one running axles . The mechanical part was supplied by the Krauss & Cie locomotive factory in Munich. The electrical part came from AEG.

The running axle was combined with the front drive wheel to form a Krauss-Helmholtz bogie, but the running axle was radially adjustable and the front driving axle was laterally movable. The rear drive axle was permanently installed in the inner frame, which also formed the frame for the engine and carried the box. So the locomotive did not have a fixed wheelbase. The springs were suspended under the bearings on the drive axles, while they were above the barrel axles. There was a motor in each half, which was located in a frame. He drove up an almost vertical rod, a dummy shaft to from which the force on the connecting rods has been transferred. The transformers were each arranged in an oil box in front of the driver's cab. The two driver's cabs were connected to one another by a side passage in the engine room and a bellows transition. The engines had an output of 800 hp each at a speed of 40 km / h. The locomotive should therefore be able to carry a load of 400 tons on a 15.5 ‰ gradient or 250 tons on a 27 ‰ gradient, which corresponds to a pulling force of 8000 kg. The motors were compensated repulsion motors with separate excitation of the valve of the Winter-Eichberg design. The speed regulation was carried out on the one hand by changing the stator voltage , on the other hand by changing the transformation ratio of the exciter transformer. Each motor had 120 carbon holders, the maximum motor voltage was 1235 volts. It was a low-speed electric motor, so no translation was necessary. The control was a step switch control, which worked with 17 hops per half of the car. The car halves were independent of each other, but they were connected together via an AC control. Each half of the locomotive weighed 48 tons, but due to the off-center motor, each half had a lateral imbalance of around three tons.

Test result

There were no noteworthy complaints about the driving characteristics and cornering maneuverability. The specified tensile force was also achieved. In the mechanical area, complaints were made about various bearings. The insufficiently fastened engine bearings therefore tended to warm up; This was even more pronounced for the jackshaft bearings. The circuit was quite reliable as it was not a new development. The high power consumption of over 100% of full load when starting up was the main reason for the unsatisfactory assessment of the motor, because the comparison machine started with just 25% full load. In addition, there was the strong phase shift , which had a negative effect on the voltage regulation in the power plant.

Whereabouts

The locomotive was not taken over by the BLS after the end of the test operation, so that it was returned to the manufacturer in 1912, who used it for further tests. See also Prussian EG 509/510 .

swell

- Claude Jeanmaire: Spiez-Frutigen-Bahn , Archive No. 59, p. 63ff