Kiln

The kiln is since the ancient times known device for dehydrating , the drying of food and consumer goods with the help of heat.

history

Since the Neolithic , people have known that grain may need to be dried for damage-free storage. An early device believed to be a kiln was found at Bab edh-Dhra on the Dead Sea . Darren were also found in Roman settlements, for example in the Roman settlement of Tegelberg in Ostallgäu. In Wales, during excavation work in 1982, the 15th-century Collfryn cereal skier was discovered and the Lion Court dredged in 2002 . In England, “Corn Drying Kiln” was excavated from Kilnsey Green in North Yorkshire. A Scottish kiln was found at the Dull site . The kilns in Ireland can be dated back to the Bronze Age through a number of recent archaeological excavations .

A typical drying plant has been reconstructed in the Highland Folk Museum in Newtonmore ( Highlands ) in Scotland.

Usage

Kilns can be divided according to the goods to be dried:

Grain skewers

In the case of grain, kilning is mainly used for preservation. Since grain can only be safely stored below 14% moisture, but depending on the weather it is threshed with a higher moisture level, the moisture must be removed by drying. If the storage were too moist, the result would be infestation with fungi and pests. Moisture in the grain can also cause spontaneous combustion . During the subsequent grinding of the grain, however, it may be necessary, depending on the "glassiness" of the grain, to "wipe" (moisten) it again to 16-17% moisture, since the dry shell splinters too much during grinding and a separation between Bran and flour would make it difficult.

Another desirable effect of Darren's production of roasted flavor when can roasting of the grain to be. A well-known product, which gets its typical aroma through kiln, is green spelled , the grain of spelled , which is harvested half-ripe and then artificially dried.

Malt kiln

In malt production , the green malt is dried, that is, kilned, as the third processing step after soaking and germination. Due to the heat and the associated removal of moisture, malt can not only be stored but also gets its typical “malty” aroma.

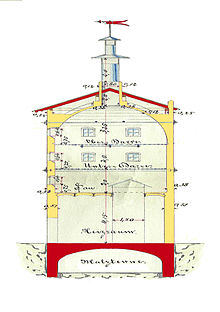

The kiln consists of a close-meshed wire mesh or a slotted perforated plate, the so-called horde, on which the green malt is piled. Hot air flows through the "pile" from below, drawing moisture from it.

In modern malthouses, the air is heated indirectly : air heated directly by oil or gas burners transfers the thermal energy to the air flowing through the green malt via a heat exchanger . Thanks to the indirect firing, the malt remains free of harmful substances and off- flavors from fossil fuels and the formation of nitrosamines is minimized. The direct lighting is almost exclusively only used for the production of aromatic specialty malts. Smoked malt, which is used for smoked beer , is produced using a beech wood fire, and more rarely an oak wood fire under the kiln. For the production of whiskey malt, peat is burned under the kiln , which gives the malt and the whiskey made from it a phenolic note. Especially the Islay whiskeys from the Scottish island of Islay are known for their peaty taste. Recently, beers with whiskey malt have also been increasingly produced.

Hop kiln

When harvested, hops have a water content of 75–84% and must be dried to a moisture level of 9–10% immediately after harvest to maintain their shelf life. Depending on the type and size of the kiln, the drying time takes about 3–5 hours. For an optimal drying result, a drying temperature of 62–68 ° C with a bed height of 20–35 cm and an air speed of 0.30–0.45 m / s is aimed for.

Other kilns

- for dried fruit in fruit growing areas

- for tobacco

- Shrimps that are too small to be peeled by hand and are therefore unsuitable for human consumption (the rotten shrimp ) are dried on kilns and then processed into animal feed, especially for chickens.

- Wood drying systems in which timber (including firewood) is extracted from its moisture

- On the Samendarre viable seeds of pine or fir cones are dried. From 1882 to 1925, a seed kiln was operated in Lingen based on the Saxon model. In the 45 years of the existence of this “Royal Hanoverian kiln”, around 30,000 kg of pine seeds were “sounded”. The empty cones were used as heating material for drying. This kiln was of great importance for the cultivation of the pine in the Emsland and for the delivery of other forestry companies throughout northern Germany.

- Linen or flax for fiber production (clothing, rope mill) is also dried on the kiln.

Designs

Hop kiln near Healdsburg , California . The kiln, built in 1905, is one of the few surviving specimens in the formerly important hop-growing region of Northern California.

See also

literature

- JE Walkowitz: Quantum leaps in archeology. In: Varia neolithica. IV, 2006. ISBN 3-937517-43-X

Web links

- German Sielhafenmuseum Carolinensiel

- Corn Drying Kilns ( Memento of September 27, 2007 in the Internet Archive ) (English)

- David Johnson, Roger Martlew, Pat Carroll, Phil Carroll: Report on the Excavation of a Corn Drying Kiln at Kilnsey Green, Kilnsey, North YorkshireKilnsey Green. (PDF; 7.2 MB) Upper Wharfedale Heritage Group, 2009, accessed on April 19, 2017 .

- Corn Drying Kiln on YouTube

- Video engl.

- Video engl.

- Video engl.

Individual evidence

- ↑ Rauchbier. In: braukultur-franken.de. Association for the promotion of Franconian brewing culture, accessed on April 19, 2017 .

- ↑ drying of hops. (PDF; 1.4 MB) In: bayern.de. Bavarian State Institute for Agriculture , accessed on April 19, 2017 .

- ↑ HMdb.org, The Historical Marker Database, entry Walters Ranch Hop Kiln , last accessed on 26 June 2012 found.