Malt

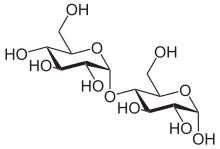

Malting is a controlled germination process that turns grain into malt . The germination process activates and forms enzymes in the grain that are later necessary for the breakdown of starch and protein during brewing as well as for whiskey production . In addition, some of the starch is broken down into smaller molecules ( polysaccharides , especially disaccharides such as maltose ). Subsequently, the sprouted grain is under controlled conditions kiln-dried , d. H. dried; The duration and temperature of kilning influence the color and aroma of the malt.

Malt production steps

The work steps in the malt house include:

-

Cleaning the brewing grain

- In particular, when the grain is delivered directly from the field during harvest, the brewing grain must be cleaned before processing. The following equipment is used for this:

- Separator / aspirator

- Magnetic separator

- Dry stone separator

- Deburrer

- Trieur .

- In particular, when the grain is delivered directly from the field during harvest, the brewing grain must be cleaned before processing. The following equipment is used for this:

-

Drying the brewing grain

- In order to preserve the life processes in the grain and to avoid mold formation or even self-ignition of the grain, the water content must not exceed 15% if the grain is stored for a longer period. For this, it may be necessary to dry the grain before storage. Just like drying the green malt on a kiln, this can also be done by ventilating the silos if the water content is slightly higher. In many parts of Germany, such as the Rhine Graben, the grain is usually harvested so dry that it is not necessary to dry it before storage. A ripening may be necessary to for freshly harvested grain dormancy overcome and full germination to achieve.

-

Switches

- When soaking in the soft house, the brewing barley (or other brewing grain) is usually moistened for 1–2 days until the water content of the grain is increased to 35–43%. A significant increase in the life process in the grain can already be seen with a water content of around 30%. Phases in which the soft goods are exposed to water ("wet soak") alternate with dry phases ("dry soak"). While the wet switch serves to accelerate the water absorption of the grain, the main purpose of the dry switch is to ventilate the grain and thus keep it alive. In the case of dead, non-germinating grains, so-called "failures", the desired conversion processes in the grain during malting cannot take place. For this reason, the dry switch usually involves extraction of carbon dioxide and ventilation with fresh air.

- (At 12–15 ° C, plenty of water, slightly alkaline, (air) oxygen.)

-

Germinate

- The soaked barley germinates on the threshing floor or today mostly in germination boxes for 4–7 days. In order to achieve the water content of approx. 43-48% necessary for the dissolving processes in the grain, additional water is added either by so-called wet evacuation or by spraying with water nozzles. Leaf and root germs develop from the seedling of the grain and enzymes are formed or activated in the grain . In order to ensure uniform germination and moisture penetration of the germinal material, the germinal material is turned at regular intervals during soaking. Depending on the malting technology, this can be done by turning spindles, rotating turner, gravity or manually.

- (At a maximum of 15–17 ° C, (air) oxygen. The result is green malt that cannot be stored .)

-

Darren

- In malt production, kilning is the drying of the green malt on a kiln to ensure a longer shelf life and transportability. Furthermore, the typical malt color and aroma substances are strengthened during kilning. During the kiln process, the green malt is dried from a moisture content of 40–45% to 4–5%. This takes place in two sub-steps: During the first phase, the withering , the temperature in the germinal material remains relatively constant and the air flowing out is always 100% saturated with moisture. The heat energy is mainly used to evaporate moisture on the grain surface, under the husk and in the easily accessible upper layers of the grain. This protects the enzymes present in the seedling. In the second phase, the drying , the temperature also rises sharply inside the grain and the water is gradually withdrawn from the grain via the capillary effect . At this stage, the exhaust air is no longer 100% saturated with moisture. The temperature level and the duration of this second phase determine the color of the malt and, later, the beer. The higher or longer, the darker the malt and the beer made from it. In the case of roasted malts, the malt can also be dried in a roaster instead of on the kiln, whereby higher temperatures are used, which largely destroy the enzymes and increase the malt color and the aroma components.

- (Drying at around 35 ° C to (3–) 4% water content, light malt must be dried quickly with a strong draft. Then kiln at over 70 ° C: light malt at 75–80 ° C, dark malt at 105–120 ° C. Root threads fall off, are sieved out. 20-25% malting loss. 100 kg barley results in around 80 kg malt.)

-

Cleaning and polishing the malt

- In this process step, the leaf and root germs and the malt debris are removed. The germs, which make up around 3–4% of the total amount, contain around 20–25% protein and are used in animal feed .

-

Mixing the malt

- Since malt is a natural product, every production batch is different, even under identical production conditions. Different batches of the malt are therefore mixed (blended) according to the specifications in order to obtain a homogeneous end product. This production step usually only takes place shortly before the finished malt is shipped to the customer.

Individual evidence

- ↑ Wilfried Seibel (Ed.): Warenkunde grain . AgriMedia, Bergen / Dumme 2005, ISBN 3-86037-257-2 .

- ↑ Ludwig Narziss, Werner Back: The beer brewery: Volume 1: The technology of malt preparation , chap. 5.1. Theory of softening, Wiley-VCH Verlag, 2012, ISBN 978-3-527-32532-0

- ^ A b Vocational school in Ulm: Specialist knowledge II - The malt . ( Memento of the original from October 27, 2011 in the Internet Archive ) Info: The archive link was automatically inserted and not yet checked. Please check the original and archive link according to the instructions and then remove this notice. (PDF) bierbrauerei.net

- ↑ Barley becomes malt ( Memento of the original from June 20, 2007 in the Internet Archive ) Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice. , at bierundwir.de, accessed on November 1, 2013