Standard signal

Standard signals are normalized electrical or pneumatic signals in process automation.

There is an abundance of standard controllers and measuring transducers (transmitters) from various manufacturers for these standard signals . The new data buses are currently replacing the standard signal concept.

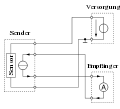

Transmitters or sensors measure process variables (temperature, level, etc.) and convert the measured value into the standard signal so that it can be used by evaluation devices with analog inputs such as B. displays, process control systems , PLC or DDC can be processed.

Common standard signals

Current or voltage signals, but also pneumatic pressure signals, can be used to transmit a process variable to an evaluation device.

Current signals according to DIN IEC 60381-1

- 0 mA… 20 mA

- 4 mA… 20 mA (with offset zero , formerly live zero )

Voltage signals according to DIN IEC 60381-2

- <0 V ... 5 V

- 0 V ... 10 V

- 1 V… 5 V (offset zero point)

- 2 V… 10 V (offset zero point)

- -10 V… 10 V (with or without offset zero point)

Ratiometric voltage signals

- 5… 95% (0.25 V… 4.75 V at = 5 V)

- 10 ... 90% (0.5 V ... 4.5 V at = 5 V)

Pneumatic pressure signal according to DIN EN 60654-2

- 0.2 bar… 1 bar

Practical application in automation

Signals with offset zero point are used in almost all industrial applications. If an electrical signal other than 0 is assigned to the start of the measuring range, wire break monitoring can be implemented. The starting signal deviating from zero for a 0 percent measured value of 4 mA or 0.2 bar is also referred to as "offset zero point". A signal of 0 mA or 0 bar is therefore always a reliable indication of a malfunction.

Current signals are preferred over voltage signals because the current signal is insensitive to electromagnetic interference (e.g. caused by switching on neighboring loads ) and voltage losses due to line resistance. The length of the signal line is only limited by the maximum load (resistance) that can be operated by the power source. Usable cable lengths of up to 1000 m are usually specified (cable type: JY (St) Y 2 × 2 × 0.8).

In addition, the 4 mA… 20 mA unit current signal offers the great advantage that the signal circuit is permanently supplied with energy. This energy can be used by transmitters for their own supply. In this case, the PLC must supply the signal circuit with energy (passive sensor). An active sensor requires an external supply for its own requirements. (For examples see module arrangement )

A former disadvantage of the current-based standard signals such as 0 mA ... 20 mA and 4 mA ... 20 mA for transmitting analog values was however that separated briefly from a test and troubleshooting the circuit had to, because for the current measurement must have the meter in series to Receiver can be switched "in between ". Meanwhile, current clamp meter available for these low measuring currents, so that no separation for current measurement is necessary.

For voltage-based signals such as 0 V… 10 V and 1 V… 10 V, the measurement is carried out in parallel to the receiver, i. H. you just touch the two contacts with the measuring tips of the voltmeter without having to disconnect the circuit.

Evaluation and conversion in the PLC / DDC

The analog input of the control / regulation always receives the same electrical quantity as a signal. Without knowing the measuring range of the converter, it is impossible to draw conclusions about the physical measured variable.

The raw signal is often referred to as 0%… 100%. Simple PLCs can only calculate with these values.

More complex control systems and modern PLCs enable conversion to the measured physical quantity.

To perform this calculation, the measuring span and the smallest measured value of the sensor are required.

example

Pressure transducer with a measuring range of 500 mbar… 2000 mbar. The measuring span is 1500 mbar, the smallest measured value is 500 mbar.

In the case of a linear characteristic , the conversion is done using the following formula:

Messwert = Rohwert × Messspanne + kleinster Messwert

With a raw value of 50% (12 mA at 4 mA ... 20 mA) this results in:

Druck = 50 % × 1500 mbar + 500 mbar = 1250 mbar

Ratiometric voltage outputs

In applications with a strongly fluctuating supply voltage, such as in motor vehicle electrical systems, or in the case of voltage supplies via batteries or accumulators, ratiometric voltage outputs are increasingly used. These outputs represent the measured value as a percentage of their supply voltage. These devices do not need a reference voltage source , the circuits work completely in relation to their supply voltage. The advantages are:

- Energy and cost savings by eliminating the reference voltage source in the transmitter

- Possibility of using the supply voltage as a reference voltage in the connected analog-digital conversion and thus energy and cost savings

- Elimination of complex supply voltage stabilization in difficult environmental conditions

- The output signal is less susceptible to interference .

A disadvantage, however, is a higher inaccuracy when the voltage source and sink work with different supply voltages, e.g. B. because a voltage drop occurs in the supply lines. In general, such circuits are supplied with a DC voltage of 5 V and provide an output signal of 10 ... 90% of their supply voltage, resulting in a nominal voltage signal of 0.5 ... 4.5 V, which has become the industry standard.

Pneumatic pressure signal

The pneumatic signal requires a compressed air network. It is well suited for parts of the plant that are at risk of explosion . Since the introduction of intrinsically safe transmitters, the pneumatic standard signal has become less and less important. The corresponding cables have a blue jacket for identification, the measuring transducers are labeled "Ex i".

Module arrangement

There are various concepts for the transmission of the current signal, which differ in the number of conductors used to the transmitter (sensor).

See also

Individual evidence

- ↑ DIN EN 60688: 2013: Electrical measuring transducers for converting electrical alternating current quantities and direct current quantities into analog or digital signals (German version of IEC 60688: 2012)

- ↑ Fluke 810 vibration meter. Accessed July 30, 2020 (German).

- ↑ METRACLIP 63 | GOSSEN METRAWATT | CAMILLE BAUER | GMC-I measurement technology. Accessed July 30, 2020 .

- ↑ Ekbert Hering, Gert Schönfelder (Hrsg.): Sensors in science and technology: functionality and areas of application

- ↑ Data sheet of an integrated ratiometric instrumentation amplifier (PDF file; 279 kB)