Tension meter

A voltage measuring device (also known as strain gauges or colloquially as voltmeter hereinafter) is used for the measurement of electrical voltages .

During the measurement, the measured variable is converted into a display of its multiple of the unit volt . The voltage measuring device consists of the actual measuring mechanism or the measuring electronics, a display and, if necessary, a series resistor or voltage divider to adapt the measuring range . For laboratory applications there are switchable multiple measuring devices with several measuring ranges and for other measured variables, which are called multimeters .

There are displayless measuring devices for industrial applications .

Embodiments

Digital measuring devices

With today's digital voltage measuring devices, the voltage is displayed directly in numeric form . The analog voltage to be measured is tapped at high resistance (parallel connection) and converted into a digital signal by means of an analog-digital converter , which controls the numerical display.

The advantage of digital voltmeters lies in their mechanical insensitivity, easy readability of the display, possibility of operation in all spatial positions, higher measuring accuracy, significantly higher input resistances, especially with small voltage measuring ranges, and lower manufacturing costs. Many digital multimeters also offer automatic range selection and, in addition to direct voltage, they can also measure alternating voltage or mixed voltage - often with an effective value acquisition.

The disadvantage of numerically indicating measuring devices is that chronological progressions cannot be followed so well. For this reason, some digital voltage measuring devices also offer a scale display in the form of a bar graph or a graphically displayed pointer in the display field (weakly recognizable in the image of the multimeter below the number field). The resolution of the numerical display is limited to 1 digit ; see digital measurement technology and digital multimeters .

Analog measuring devices

Electrostatic measuring mechanisms

With an electrostatic voltmeter , the voltage leads to a pointer deflection without current flow . The mechanical force arises from the repulsion of the same name or the attraction of unlike charges. The simplest electrostatic voltmeter is the electroscope and was mainly used to measure higher DC voltages. More precise measuring devices had three electrodes, one of which was a movably mounted sheet metal between the other two electrodes. The voltage was connected to both fixed electrodes and one pole to the movable one. The devices often have a light pointer (display principle of the mirror galvanometer , which is not, however, an electrostatic measuring device). They are also suitable for AC voltage .

Moving iron and moving coil measuring mechanisms

The voltage measurement takes place via the detour of measuring a current which is proportional to the voltage due to the resistance of the drive coil, possibly supplemented by a series resistor. The device actually measures a current with its pointer deflection, but the scale is labeled with the corresponding voltage values. With the moving-coil measuring mechanism, the Lorentz force generates the pointer deflection. In the case of the moving iron measuring mechanism , it is the magnetic repulsion of iron parts that are located inside a fixed coil. Moving coil measuring devices always have a series resistor, moving iron measuring devices often not - with these, the coil can be designed with a sufficiently high resistance. Moving coil measuring devices measure the polarity-correct mean value; To measure AC voltage, you must have a measuring rectifier. Moving iron measuring mechanisms measure the effective value ; they don't need a rectifier. Measuring devices with these measuring mechanisms are usually marked on the scale with an accuracy class .

Tube voltmeter

Tube voltmeters are voltage measuring devices that are equipped with electron tubes and have a much higher input resistance than was otherwise possible in their time. Today they have been completely replaced by digital measuring devices equipped with electrometer amplifiers (operational amplifiers with JFET or MOS input).

Transmitter

In industrial metrology and automation technology, no indicating measuring devices are used, but measuring transducers that deliver a standardized electrical signal for central processing. In terms of analog technology, this can be a standard signal, for example as 4… 20 mA. It can also be a digital output signal for transmission via a data bus , which is called a fieldbus in this context . These measuring devices with a digital measuring signal at the output are also called measuring converters .

Voltage converters (special measuring transformers) are used as measuring transducers for measuring range adjustment and for potential separation at high AC voltages . The nominal value of the output voltage is preferably 100 V.

Compensator

Voltage compensators are suitable for precision measurements and for measurements without any current load on the measuring object (at least when calibrating) . However, they are being replaced by electronic devices with comparable qualifications.

use

The voltmeter is connected to the two points of a circuit between which the voltage is to be measured. If you want to measure the voltage that drops across a component or measurement object, the voltmeter is connected in parallel. This can be done for short tests with test probes without having to intervene in the circuit. Therefore voltage measurement is the most common form of electrical control. Current measured values can often be obtained indirectly from a voltage measurement if the value of the resistance R is known, over which the measurement is being made (current I = U / R with U = measured voltage).

- Measuring range

- Every moving coil or moving iron measuring mechanism has a maximum deflection (full deflection) at a maximum current I max . At the same time, it has an inherent resistance (internal resistance R i ), which means that at full deflection a maximum voltage is applied to the measuring mechanism ( U max = R i ∙ I max ). For further measuring ranges it is operated via switchable series resistors, see under analog multimeter . If the maximum voltage is exceeded, the measuring mechanism or the series resistors can be overloaded. For measuring devices with a class symbol , a permissible overload capacity is specified by standardization.

This overload problem does not exist in this form with digital voltage measuring devices, as their internal resistance is very high and therefore only converts little power. If the end value of the measuring range is exceeded , depending on the version, a multi-stage voltage divider automatically switches to the next higher measuring range.

For reasons of safety, the maximum permissible voltage is usually in the range 700 V to 1000 V and is partly printed on the measuring device and partly specified in the instructions for use.

Measuring range adjustment, errors due to internal consumption

Ideal measuring device vs. real measuring device

An ideal measuring device has no internal consumption from the measuring object; this means that the internal resistance of the voltmeter must be infinitely large. In reality, however, it draws a current like an ohmic resistor. This is identified in the equivalent circuit diagram by a parallel connection of the ideal measuring device with its internal resistance. It has grown historically - due to the moving-coil measuring mechanism that has been common for a long time - a series connection is still partially drawn. Then - if the circuit symbol is to stand for an ideally lossless measuring device - its resistance must have the value zero, which is not compatible with a designation as a voltage measuring device.

For devices with moving coil measuring mechanism

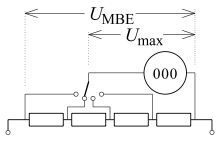

In order to adapt a moving -coil voltmeter to the desired measuring range , it is connected in series with a suitable series resistor R v . Of the voltage U MBE that can be measured at the end of the measuring range, part U max is allocated to the measuring mechanism, the rest U v = U MBE - U max to the series resistor.

- example

- The measuring mechanism has a resistance R m = 750 Ω and deflects at the maximum current I max = 200 µA up to the end value of the scale . It should be used in a voltage measuring device for the measuring range U MBE = 10 V. At full deflection, the voltage U max = R m ∙ I max = 750 Ω ∙ 0.200 mA = 150 mV is across the measuring mechanism. So there must be U v = 10.00 V - 0.15 V = 9.85 V at the series resistor. Since the current of 200 µA also flows through it, this results in R v = U v / I max = 9.85 V / 0.2 mA = 49.25 kΩ. The total resistance of the series connection (internal resistance R U of the measuring device) is then R U = R v + R m = 50.00 kΩ.

In the case of multimeters based on moving coils, I max is usually a constant that is valid for all measuring ranges, or vice versa, the internal resistance in each range is different - the greater the larger the measuring range. For an easy calculation of the internal resistance, a voltage-related resistance ρ = 1 / I max is specified for voltmeters in Ω / V (ohms per volt), also as a constant for all measuring ranges. This information has to be multiplied by the respective full scale value in order to obtain the actual internal resistance.

- example

- The measuring device calculated above has a measuring mechanism resistance of 750 Ω with a measuring range of 150 mV. This implies ρ = 750 Ω / 150 mV = 5.00 kΩ / V. If you use it for a measuring range of 10 V, it therefore has the resistance R U = ρ · U MBE = 5 kΩ / V ∙ 10 V = 50 kΩ, as calculated in another way above.

The fact that the current determining the measurement flows through the voltmeter means that every measurement falsifies the original conditions on the measurement object, since an (additional) current is drawn for the measurement. Therefore this should be kept as small as possible, i.e. H. the resistance of the voltmeter R U should be as high as possible.

Target in the displayed image in the upper circuit, the at R 1 falling voltage U 1 can be measured, it is noted that the source of this voltage a source resistance R q = R 1 || R 2 has. (Note: The source of U 0 , as an ideal voltage source, has zero source resistance.) The circuit below is electrically equivalent to the one above. If the measuring device is connected to it, a smaller measured value U m is obtained instead of U 1 because R q and R U form a voltage divider . The resulting feedback deviation , given as the relative measurement deviation f , is

- example

- With R q = 5 kΩ and R U = 50 kΩ: the current consumption of the voltmeter inside the voltage source at R q causes a partial voltage to drop in the ratio of the resistances 5 kΩ / (5 kΩ + 50 kΩ) = 9%; the measured value is determined with a relative measurement deviation of - 9%.

With digital-electronic devices

With digital voltage measuring devices it is not usual to extend the range with a series resistor; the internal resistance of these measuring devices is typically 1 to 20 MΩ in all ranges; The standard is 10 MΩ. Rather, voltage dividers are used here ; this is built in internally in multimeters. Due to the high internal resistance, the problem of feedback deviation (circuit influence error) does not occur to the same extent as with moving-coil voltmeters.

The disadvantage of such a high internal resistance is that the voltage display is not clear when measuring on disconnected circuit parts; it is then influenced by fields in the environment, which reload the circuit part (for example, a switched off or interrupted line or just the measuring line that is not connected) by means of influence or induction.

- example

- If the measuring device has an internal resistance of 10 MΩ and the source 5 kΩ, the portion 5 kΩ / (5 kΩ + 10 MΩ) = 0.5 ‰ of the source resistance is lost from the voltage to be measured. This systematic measurement deviation of - 0.5 ‰ is in the range or below the measuring device error limits and can usually be neglected.

See also

- Measurement categories with regard to the permitted areas of application of measuring and testing devices for electrical equipment and systems.

Web links

Individual evidence

- ↑ The term voltmeter has been replaced in the standardization, since volt is the unit and not the physical quantity that is actually measured.

- ↑ A. Varduhn, W. Nell: Handbook of Electrical Engineering Volume II . Fachbuchverlag, Leipzig 1951, page 159