Glow plug

A glow plug is an electrical heating element in the combustion chamber of internal combustion engines and heaters. The glow plug is only briefly heated electrically when it is started.

Glow plugs are used as:

- Cold start aid for diesel engines

- Ignition device when operating glow-igniter engines (typically: model construction engines )

- Ignition device when starting gas turbines and oil heating systems operated with oil or kerosene

- Starting device for evaporating and igniting liquid fuel in parking heaters

Glow plug as a cold start aid for diesel engines

The diesel fuel injected into the combustion chamber when the diesel engine is cold usually does not ignite by itself.

Reasons for this are:

- The walls of the combustion chamber (cylinder walls, piston crown) are still cold and have a high specific heat capacity (ferrous material). In contrast, when the electric starter motor starts, the piston speed is low, the compression heat generated by the compressed air is lost too quickly to the cylinder walls and the piston crown due to the low thermal capacity and, even if the thermal conductivity is low.

- Chamber motors in particular have a large surface area that is effective for the flow of heat. A cold engine can be started without glow plug support with direct injection above −10 ° C air temperature, with vortex chamber injection above +30 ° C and with pre-chamber injection only from above approx. +60 ° C.

- The cold engine has higher blow-by losses , that is, the compressed air can escape from the combustion chamber past the piston rings , so that the final compression pressure and thus the final compression temperature are lower. Due to the lower piston speed when starting, the blow-by losses increase further.

- Different fuel qualities, especially if a multi-fuel engine is to burn fuels that are unwilling to ignite.

For these reasons, an electrically heatable glow plug (glow plug, glow plug) is inserted in the combustion chamber, which is preheated in the start phase (part of the preheating system ). The current is approx. 20-40 amperes per cylinder, which in addition to the starter motor, strain the starter battery. After the start, the glow plug continues to heat for some time to reduce pollutants in the exhaust gas due to unburned hydrocarbons.

Technical developments have reduced the time it takes to heat up the glow plugs from a few minutes (jokingly known as the “ Rudolf Diesel minute minute” in car magazines ) to a few seconds.

The temperature of the glow shaft of metal glow plugs reaches up to approx. 1,000 ° C, that of ceramic glow plugs up to 1,300 ° C.

In the case of direct injection engines, due to the compact combustion chamber, preliminary glowing is necessary at most when the outside temperature is winter. The glow plug is occasionally switched on during the cold run in order to achieve combustion with lower noise and emissions in this phase.

The electrical contact is made via a threaded bolt and the screw-in thread.

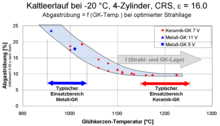

The diagram opposite shows the relationship between the glow plug glow temperature and the so-called exhaust gas opacity (visible smoke) for a modern direct-injection diesel engine with an optimized injection jet and glow plug position. It has been shown that a maximum reduction in exhaust gas opacity during a cold start and cold idling can only be achieved with very high annealing temperatures above 1,150 ° C.

Metallic glow plugs

A metallic glow plug consists of a helix that is pressed into a steel tube with an insulating powder ( magnesium oxide ). The filament itself consists of two parts - the incandescent filament in the tip and the control filament in the rear part. The incandescent filament consists of a high-alloy steel with a temperature-independent resistance , while the control filament has a resistance that increases with temperature. When the candle is cold, this results in rapid heating, especially at the tip, and a curtailment as soon as the area of the control coil is heated.

Metal glow plugs are available in two designs: on-board voltage glow plugs with an operating voltage of 11 volts and so-called low-voltage glow plugs with an operating voltage of less than 11 volts. In 2006, on-board voltage glow plugs allowed heating times of approx. 6 seconds to 850 ° C.

An even shorter heating time is possible with low-voltage glow plugs. When heating up, these glow plugs can be activated with a voltage above their operating voltage. The voltage, which is reduced after heating, is generated from the on-board voltage with an electronic glow time control unit through pulse width modulation . This enables heating times of 3 s to 1000 ° C to be achieved.

Ceramic glow plugs

Glow plugs with silicon nitride ceramic coated heating conductors have been developed for the combination of high thermal shock and hot gas corrosion exposure . Modern passenger car engines with a low compression ratio also require glow plugs that allow maximum temperatures of up to 1,300 ° C and long glow times without aging at over 1,150 ° C. The desire for an instant start similar to a gasoline engine, even at very low temperatures, necessitates heating speeds of up to 600 K / s. This is possible with ceramic NHTC (New High Temperature Ceramic) glow plugs.

The main advantage of ceramic glow plugs is that the lowering of the glow temperature due to aging, which can often be observed with metallic glow plugs, and the gradual deterioration of the cold start and cold running behavior that this causes, hardly occurs. Even at very high annealing temperatures of 1,200 ° C, the annealing temperature typically drops by less than 50 K after 3,000 operating hours.

SRC glow plug

The sheathing of the metal coils of an SRC (Self Regulated Ceramic) glow plug is achieved by sintering, that is, the coil is pressed around and then the pressed part, including the coil, is sintered (fired) to form the ceramic . As with metallic glow plugs, there is a heating coil and a control coil. The heating element is pressed gas-tight into a metal housing. By adapting the heating resistor, there are also 11 volt and low voltage versions with and without control coil. The control of ceramic glow plugs via the glow time control unit is carried out in the same way as metallic glow plugs.

NHTC glow plug

NHTC glow plugs have a non-metallic heating conductor, so they are all-ceramic. They achieve the highest heating rates and final temperatures and can be used for up to 10 minutes at 1200 ° C for intermediate annealing (overrun operation) and for burning out the particle filter . It is manufactured by jointly sintering a green compact from the various functional ceramic raw materials (conductive ceramic, PTC ceramic , insulating ceramic).

Glow plug as ignition device for the glow igniter engine

Glow ignition engines are internal combustion engines without controlled high-voltage ignition by means of arcing.

Instead of this, a glow plug with a permanently red-hot wire coil is mounted, which is coated with a wafer-thin catalyst material (usually a platinum - iridium alloy) by vapor deposition . This ensures that the fuel-air mixture ignites. To start the motor, the wire coil is charged with electrical current and made to glow. After a short operating time, the power supply can be switched off, as the glow plug now continues to glow due to the heat of combustion.

The ignition point (point in time when the mixture ignites) is determined by the heat value of the glow plug, the compression of the engine and the fuel mixture.

The octane number of the fuel is also important .

Typical thread dimensions for commercial static and automotive engines: 1/4 " × 32, inch thread; max. 6 mm long

Glow plugs in gas turbines and oil heaters

Inflammation devices on gas turbines operated with oil or kerosene , as well as oil heating systems, do not require a catalytic coating, since the ignition temperature is low enough even without it.

Manufacturer

literature

- Peter A. Wellers, Hermann Strobel, Erich Auch-Schwelk (edit.): Vehicle technology expertise. 5th edition. Holland and Josenhans, Stuttgart 1997, ISBN 3-7782-3520-6 .

- Peter Gerigk, Detlev Bruhn, Dietmar Danner: Automotive engineering. 3. Edition. Westermann, Braunschweig 2000, ISBN 3-14-221500-X .

- Max Bohner, Richard Fischer, Rolf Gscheidle: Expertise in automotive technology. 27th edition, Europa-Lehrmittel, Haan-Gruiten 2001, ISBN 3-8085-2067-1 .