Impactor

Impactors are particle measuring devices or particle separators and are used in process engineering to determine particle masses and particle sizes (distributions) or to separate particles in a gas volume flow.

Working principle

The functional principle of an impactor is based on the deflection of a free jet (gas volume flow ) through an angle of 90 °. The gas and the particles contained in it are accelerated through a nozzle, whereby the particles can only follow the flow deflection to a limited extent, so that the more inert particles hit a baffle plate. An adhesive covering, which can consist of glass fiber material, for example, is intended to ensure that separated particles remain on the impact plate. The measuring principle of the single-stage impactor thus corresponds to that of the conimeter .

A characteristic for characterizing impactors is the separation diameter d 50 , which indicates the aerodynamic diameter at which the impactor has a separation efficiency of 50%.

Measurement and analysis

The particle masses are determined gravimetrically ; the number of particles is determined by weighing. The impactor stage is weighed before and after the measurement is carried out. The difference is the weight of the separated particles. The weighing becomes more accurate the lower the weight of the impactor stage.

Properties and parameters

The respective nozzles are usually located in a nozzle plate. Since it is difficult in practice to create the required flow conditions with a single nozzle, there are several nozzles in a nozzle plate, which are usually designed as round or slot nozzles. In addition to the nozzle shape, the nozzle diameter, nozzle length and distance between the nozzle and baffle plate are particularly important. Other important parameters are flow rate and pressure. By lowering the pressure, the separation diameter can be reduced due to the increase in the mean free path of the gas.

The particle density is included in the design of the impactor via the aerodynamic diameter .

Designs

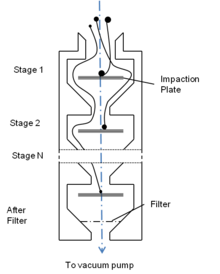

Cascade impactor

Cascade impactors are used for fractionating dust measurement . In this design, several single-stage impactors are connected in series. With an increasing number of stages, the width of the nozzle of the nozzle plate becomes smaller. In this way, smaller and smaller particles can be separated.

The EN ISO 23210: 2009-12 standard specifies a two-stage cascade impactor for determining the PM 10 and PM 2.5 mass concentrations when measuring emissions .

Andersen impactor

The impactor named after Ariel A. Anderson is a cascade impactor which has a large number of similar nozzles in each nozzle plate and whose impact plates consist of agar dishes with a nutrient medium. The Andersen impactor is used to classify airborne germs ( bioaerosols ).

Devices that are used to measure particles of non-biological origin are also sold under the name Andersen Impaktor. In the pharmaceutical industry, for example, the Andersen impactor is used to measure the particle size in pharmaceutical dosage forms such as inhalation sprays , powder inhalants and nasal sprays .

Berner impactor

The Berner impactor is named after Axel Berner, who was employed at the 1st Physics Institute of the University of Vienna at the time the impactor was developed. An essential feature of the Berner impactor are four individual, identical cascade impactors in parallel operation, which are connected to a common suction line, but are operated differently so that finer subdivisions of the dust to be measured are possible. This type of impactor has been modified over the years, for example as the Bern low-pressure impactor (BLPI).

Low pressure impactor

A low pressure impactor is a cascade impactor that operates at reduced pressure. By lowering the pressure, the influence of the gas molecules on the particles to be separated is reduced so that smaller particles can also be separated.

Electric low pressure impactor

An electrical low pressure impactor ( English Electrical Low Pressure Impactor , ELPI) is operating at low pressure cascade impactor, in which the particles prior to the deposition by means of corona discharge have to be electrically charged. The particles hitting the respective baffle plates generate a current signal that provides information about the respective number concentration. Electric low-pressure impactors allow the real-time identification of particles.

The electrical low pressure impactor can also be used to characterize test aerosols .

Next generation impactor

The Next Generation Impactor (NGI) is a 7-stage cascade impactor specially developed for the pharmaceutical industry, which, like the Andersen impactor, can be used to measure the particle sizes in medicinal aerosols (inhalation sprays, powder inhalants, nasal sprays). Depending on the flow rate of the carrier gas, it covers particle sizes from 0.24 µm to 11.7 µm. The air flow is directed horizontally and zigzag through the NGI via the nozzle plates of stages 1 (a hole with a 14.3 mm diameter) to 7 (630 holes with a diameter of 0.206 mm each) and the collector for the fines. The medicinal substance precipitated in the separating containers of each stage is rinsed out quantitatively and subjected to a content determination. A gravimetric determination is also possible in terms of equipment.

Restrictions

The maximum speed of the particles in the free jet is equal to the speed of sound , which is also referred to as the “critical speed”. That limits the interpretation. Particles also bounce off at increased speeds. Another difficulty is the manufacture of the nozzle plate, since drilling very small holes (<0.2 mm) is a manufacturing challenge.

Areas of application

Impactors are used to record particles for both emission and immissions measurement . They also are used to determine culturable mold spores used. Impactors are also used to check the effectiveness of droplet eliminators .

Individual evidence

- ↑ a b VDI 2066 sheet 10: 2004-10 Measurement of particles; Dust measurement in flowing gases; Measurement of emissions from PM 10 and PM 2.5 at guided sources according to the impaction method (Particulate matter measurement; Dust measurement in flowing gases; Measurement of PM 10 and PM 2.5 emissions at stationary sources by impaction method). Beuth Verlag, Berlin, p. 7.

- ^ Lothar Laskus: Acceleration distances of particles in impactor jets. In: Hazardous substances - cleanliness. Air . 72, No. 9, 2012, ISSN 0949-8036 , pp. 385-389.

- ↑ a b VDI 2066 sheet 5: 1994-11 measurement of particles; Dust measurement in flowing gases; Fractional dust measurement using the Impaction Method - Cascade Impactor (Particulate Matter Measurement; Dust Measurement in Flowing Gases; Particle Size Selective Measurement by Impaction Method - Cascade Impactor). Beuth Verlag, Berlin, p. 4.

- ↑ Kvetoslav Spurny (Ed.): Analytical Chemistry of Aerosols: Science and Technology. CRC Press, Lewis Publishers, New York 1999, ISBN 1-56670-040-X , p. 6.

- ↑ VDI 2066 sheet 10: 2004-10 measurement of particles; Dust measurement in flowing gases; Measurement of emissions from PM 10 and PM 2.5 at guided sources according to the impaction method (Particulate matter measurement; Dust measurement in flowing gases; Measurement of PM 10 and PM 2.5 emissions at stationary sources by impaction method). Beuth Verlag, Berlin, p. 20.

- ^ Franz Joseph Dreyhaupt (ed.): VDI-Lexikon Umwelttechnik. VDI-Verlag Düsseldorf 1994, ISBN 3-18-400891-6 , pp. 635-636.

- ↑ a b VDI 3867 sheet 6: 2012-12 Measurement of particles in the outside air; Determination of the particle number concentration and number size distribution of aerosols; Electrical Low Pressure Impactor (ELPI) (Measurement of particles in ambient air; Determination of the particle number concentration and number size distribution of aerosols; Electrical Low Pressure Impactor (ELPI)). Beuth Verlag, Berlin, p. 6.

- ↑ a b c Sheldon Kay Friedlander : Smoke, Dust, and Haze - Fundamentals of Aerosol Dynamics . John Wiley & Sons, New York 1977, ISBN 0-471-01468-0 , p. 164.

- ↑ Lothar Laskus, Dieter Bake: Experiences in the particle size analysis of air dust with the Andersen cascade impactor. In: Dust - cleanliness. Air . 36, No. 3, 1976, ISSN 0949-8036 , pp. 102-106.

- ↑ DIN EN ISO 23210: 2009-12 Emissions from stationary sources - Determination of the mass concentration of PM10 / PM2.5 in exhaust gas - Measurement at low concentrations with impactors (ISO 23210: 2009); German version EN ISO 23210: 2009. Beuth Verlag, Berlin, p. 13.

- ^ Ariel A. Anderson: New sampler for the collection, sizing, and enumeration of viable airborne particles. In: J. Bacteriol. 76, 1958, pp. 471-484.

- ↑ James H. Vincent: Aerosol Sampling - Science, Standards, Instrumentation and Applications . John Wiley & Sons, Chichester 2007, ISBN 978-0-470-02725-7 , p. 455.

- ↑ European Pharmacopoeia 9.0, Volume I, Chapter 2.9.18 “Preparations for inhalation: Aerodynamic assessment of fine particles”, Apparatus D. Ed. EDQM Council of Europe.

- ↑ Axel Berner: Practical experience with a 20-stage impactor. In: Dust - cleanliness. Air. 32, No. 8, 1972, ISSN 0949-8036 , pp. 315-320.

- ↑ Risto E. Hill Arno, Esko I. Kauppinen: On the performance of the Berner Low Pressure Impactor. In: Aerosol Sci. Technol. 14, No. 1, 1991, ISSN 0278-6826 , pp. 33-47.

- ↑ Johannes Pelzer, Oliver Bischof, Willem van den Brink, Martin Fierz, Harald Gnewuch, Henna Isherwood, Markus Kasper, Andreas Knecht, Thomas Krinke, Axel Zerrath: Devices for measuring the number concentration of nanoparticles. In: Hazardous substances - cleanliness. Air. 70, No. 11/12, 2010, ISSN 0949-8036 , pp. 469-477.

- ↑ James H. Vincent: Aerosol Sampling - Science, Standards, Instrumentation and Applications . John Wiley & Sons, Chichester 2007, ISBN 978-0-470-02725-7 , p. 457.

- ↑ Albert Hellmann, Kilian Schmidt, Siegfried Ripperger, Johannes Pelzer, Klaus W. Müller: Generation of defined reference aerosols of ultra-fine particles with a spark generator. In: Hazardous substances - cleanliness. Air. 72, No. 11/12, 2012, ISSN 0949-8036 , pp. 467-472.

- ↑ VDI 3867 sheet 6: 2012-12 Measurement of particles in the outside air; Determination of the particle number concentration and number size distribution of aerosols; Electrical Low Pressure Impactor (ELPI) (Measurement of particles in ambient air; Determination of the particle number concentration and number size distribution of aerosols; Electrical Low Pressure Impactor (ELPI)). Beuth Verlag, Berlin, p. 2.

- ↑ European Pharmacopoeia 9.0, Volume I, Chapter 2.9.18 “Preparations for inhalation: Aerodynamic assessment of fine particles”, Apparatus E. Ed .: EDQM Council of Europe.

- ↑ DIN ISO 16000-20: 2015-11 Indoor air pollution ; Part 20: Detection and enumeration of mold; Determination of the total number of spores (ISO 16000-20: 2014). Beuth Verlag, Berlin, p. 11.

- ↑ VDI 3679 Part 3: 2010-6 wet separator; Droplet eliminators (wet separators; mist eliminators). Beuth Verlag, Berlin, p. 20.