Cascade impactor

A cascade impactor is a device for the fractional recording of the dust mass in gases. With its help, a particle size distribution can be determined depending on the particle diameter. A cascade impactor can be used both for the detection of airborne dust and for dust measurement in flowing gases. The EN ISO 23210: 2009-12 standard specifies a two-stage cascade impactor to determine the PM 10 and PM 2.5 mass concentrations . Cascade impactors were first described in a publication from 1945.

Measuring principle

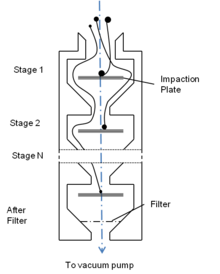

The measuring principle of a cascade impactor is based on the fact that, due to their inertia , particles cannot or only to a limited extent follow sudden changes in direction of the flow that entrains them, and particles of different sizes with the same density have different inertias. A cascade impactor essentially consists of several impactor stages, each of which consists of one or more nozzles and a baffle plate. A dusty gas flow is passed through the nozzle and deflected by 90 ° due to the baffle plate. Particles with excessive inertia cannot follow the flow deflection and are deposited on the baffle plate. In order for the separated particles to adhere, there is a collecting plate on the baffle plate, which can for example consist of fiberglass material .

Decisive for the fractionation of the particles are the nozzle length and width as well as the distance between the baffle plate and the nozzle. By reducing the nozzle width with each impactor stage, the flow velocity is increased so that a smaller particle diameter can be detected with each stage. The last stage is followed by a filter that is supposed to collect the particles that have not been separated. The collecting plates and the filter are weighed after being exposed to dust .

The nozzles can be holes of the same size, but also slot nozzles. Nozzle plates and baffle plates can be separated from one another in terms of equipment, but there are also baffle plates in which the nozzles of the next stages are installed. The flow velocities in the nozzles range between 3 m / s and 4 m / s in the first stage and between 100 m / s and 200 m / s in the last stage.

The individual levels do not show ideal dividing lines. Rather, each stage can be assigned an aerodynamic particle diameter at which the separation probability is 50%. The accuracy of the weighing is decisive for the accuracy of the measuring process. Since a sufficient mass of dust must be available for the impactor measurement, a sufficiently large gas volume flow is necessary. This is often achieved by a large number of similar nozzles connected in parallel in an impactor stage.

A size range from approx. 20 µm down to 10 nm can be covered by means of cascade impactors . They can be used directly in hot, chemically aggressive gases. High temperature cascade impactors are designed for temperatures up to over 1000 ° C.

variants

The cascade impactor has undergone numerous modifications and adjustments over time. The better-known variants of the cascade impactor include, for example, the Bern impactor, in which four identical cascade impactors are connected in parallel to achieve finer particle fractions, and the electrical low-pressure impactor , which works as a combination of cascade impactor and aerosol electrometer. Cascade impactors are also used to record bioaerosols , in that the baffle plate consists of a substrate suitable for the recorded particles of biological origin.

A two-stage cascade impactor must be used to determine the PM 10 and PM 2.5 mass concentrations when measuring emissions in accordance with the EN ISO 23210: 2009-12 standard. The PM 10 fraction is collected on the second impactor stage, the PM 2.5 fraction on the final filter. The first impactor stage is used for coarse separation.

Fine quartz dust (PM 4 ) is also recorded with a two-stage cascade impactor. Here both impactor stages are used for coarse separation.

literature

- VDI 2066 sheet 5: 1994-11 measurement of particles; Dust measurement in flowing gases; Fractional dust measurement using the impaction method; Cascade Impactor (Particulate Matter Measurement; Dust Measurement in Flowing Gases; Particle Size Selective Measurement by Impaction Method; Cascade Impactor). Beuth Verlag, Berlin. ( Summary and table of contents online )

Individual evidence

- ↑ a b Lothar Laskus, Dieter Bake: Experiences in the particle size analysis of air dust with the Andersen cascade impactor. In: Dust - cleanliness. Air . 36, No. 3, 1976, ISSN 0949-8036 , pp. 102-106.

- ↑ a b VDI 2066 sheet 5: 1994-11 measurement of particles; Dust measurement in flowing gases; Fractional dust measurement using the Impaction Method - Cascade Impactor (Particulate Matter Measurement; Dust Measurement in Flowing Gases; Particle Size Selective Measurement by Impaction Method - Cascade Impactor). Beuth Verlag, Berlin, p. 3.

- ↑ a b DIN EN ISO 23210: 2009-12 Emissions from stationary sources; Determination of the mass concentration of PM10 / PM2.5 in the exhaust gas; Measurement at low concentrations with impactors (ISO 23210: 2009); German version EN ISO 23210: 2009. Beuth Verlag, Berlin, p. 13.

- ↑ Axel Berner: On the theory of the measurement of aerosol size distributions by means of simple and multiple cascade impactors. In: Dust - cleanliness. Air. 36, No. 9, 1976, ISSN 0949-8036 , pp. 385-390.

- ↑ Sheldon Kay Friedlander : Smoke, Dust, and Haze - Fundamentals of Aerosol Dynamics . John Wiley & Sons, New York 1977, ISBN 0-471-01468-0 , p. 164.

- ^ Günter Baumbach: Air pollution control. 2nd Edition. Springer-Verlag, Berlin / Heidelberg / New York 1992, ISBN 3-540-55078-X , p. 214.

- ↑ Carsten Möhlmann, Johannes Pelzer, Albert Hellmann, Jens Niklas: Metrological determination of ultrafine and nanoparticles in mechanical processing of nanomaterials and their composites. In: Hazardous substances - cleanliness. Air . 72, No. 11/12, 2012, ISSN 0949-8036 , pp. 463-465.

- ↑ Thomas Brunner, Juergen Fluch, Ingwald Obernberger, Ragnar Warnecke: Investigations of aerosol formation pathways during MSW combustion based on high-temperature impactor measurements. In: Fuel Process. Technol. 105, 2013, ISSN 0378-3820 , pp. 154-160.

- ↑ Axel Berner: Practical experience with a 20-stage impactor. In: Dust - cleanliness. Air. 32, No. 8, 1972, ISSN 0949-8036 , pp. 315-320.

- ↑ VDI 3867 sheet 6: 2012-12 Measurement of particles in the outside air; Determination of the particle number concentration and number size distribution of aerosols; Electrical Low Pressure Impactor (ELPI) (Measurement of particles in ambient air; Determination of the particle number concentration and number size distribution of aerosols; Electrical Low Pressure Impactor (ELPI)). Beuth Verlag, Berlin, p. 3.

- ↑ James H. Vincent: Aerosol Sampling - Science, Standards, Instrumentation and Applications . John Wiley & Sons, Chichester 2007, ISBN 978-0-470-02725-7 , p. 481.

- ↑ Astrid C. John, Thomas AJ Kuhlbusch, Heinz Fißan, Günter Bröker, Karl-Josef Geueke: Development of a PM 10 / PM 2.5 cascade impactor for measuring the emission of fine dust. In: Hazardous substances - cleanliness. Air. 59, No. 11/12, 1999, ISSN 0949-8036 , pp. 449-454.

- ↑ VDI 2066 sheet 10: 2004-10 measurement of particles; Dust measurement in flowing gases; Measurement of emissions from PM 10 and PM 2.5 at guided sources according to the impaction method (Particulate matter measurement; Dust measurement in flowing gases; Measurement of PM 10 and PM 2.5 emissions at stationary sources by impaction method). Beuth Verlag, Berlin, p. 10.

- ↑ VDI 2066 sheet 11: 2018-05 Measurement of particles; Dust measurement in flowing gases; Measurement of emissions of crystalline silicon dioxide (quartz and cristobalite) in the PM 4 fraction (Particulate matter measurement; Dust measurement in flowing gases; Measurement of emissions of crystalline silicon dioxide (quartz and cristobalite) in the PM 4 fraction). Beuth Verlag, Berlin, p. 10.