Controlled living space ventilation

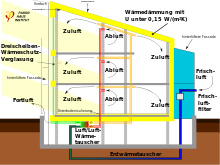

A controlled living space ventilation ( KWL ) is a mechanical ventilation for the defined ventilation of apartments. A distinction is made between decentralized and centralized ventilation. Depending on the equipment, a heat exchanger extracts heat from the exhaust air and thus preheats the supply air. There are different systems of controlled living space ventilation, which differ on the one hand through individual devices and central devices and on the other hand according to the functional principle (exhaust air system, supply air system, supply and exhaust air system, with and without heat recovery, with heat pump). In Germany, sales for residential ventilation amounted to € 455 million in 2015, and € 56.5 million in Austria in 2014.

KWL can also be used for soundproofing : B. can not sleep with the window open due to traffic noise, his bedroom can be ventilated using KWL.

Most KWL systems contain air filters . They filter the supply air before distributing it in the connected rooms. This can benefit allergy sufferers and means that there is less dust in the home.

An uncontrolled domestic ventilation , however, is the free residential ventilation via window ventilation, joint ventilation or ventilation shaft.

General

As better and better insulated buildings and passive houses appeared at the end of the 20th century, it became clear that the building shell of these houses is so airtight that moisture (through exhalation, sweating, cooking, showering, etc.) and odors (cooking, Toilet) can no longer get outside to a sufficient extent through joints (on the frames of windows and doors, on roller shutter boxes, through cellar windows, etc.) and, conversely, too little outside air ("fresh air") enters the house. It is not uncommon for mold to develop in damp rooms, especially in the bathroom.

Due to the much better thermal insulation of the building envelope, the proportion of ventilation heat loss in the total heat loss of a building has increased. In order to be able to do without an expensive central heating installation in low-energy and passive houses, it became necessary to automate the ventilation of houses and to retain the heat content of the exhaust air via a heat exchanger and to feed it into the supply air (" heat recovery "). An electronic control controls the air volume and prevents the heat exchanger from freezing. This means that ventilation - unlike ventilation through a window - is largely independent of wind speed and direction as well as the temperature difference between inside and outside. This is how the term controlled living space ventilation (KWL) came about .

The air is filtered before it is led into the rooms. This also prevents flying insects from entering the house with the air.

The higher the efficiency of the heat exchanger, the less heat energy is extracted from the inside of the building. The controlled ventilation of the living space is intended to ensure that excess humidity and air pollutants - such as carbon dioxide - are removed.

How airtight a building envelope is can be determined with a blower door test . In many old buildings, old windows and doors mean that - especially in wind and / or cold - the air exchange between inside and outside is high. New windows have two or three sealing levels.

Controlled living space ventilation works almost silently. The ventilation ducts are usually installed in the floor structure under the screed . Vertical cables can be laid in normal installation shafts , vertical wall recesses and possibly in cable shafts or in simple partition walls (e.g. made of plasterboard ).

Past and present

See also - Ventilation: leaking building envelope in old buildings

While forced ventilation via ventilation shafts running vertically through the building has been provided for a long time in the cramped living conditions of large inner-city rental houses, in most other buildings the exchange of air through the joints between window sashes and window frames ( joint ventilation ) and through that of ovens and windows was sufficient Chimneys caused negative pressure.

It is assumed that the naturally occurring air exchange before the building envelope was sealed, and in particular the replacement of windows and doors, was up to 40 times higher than is the case with modernized buildings.

A comparison of the influencing factors shows the significant change in the average daily amount of moisture generated by a 4-person household (in kg):

| Humidification through | Earlier | today | causes |

|---|---|---|---|

| Cook | 1.6 | 1.2 | It is less time-consuming and less common to cook it yourself. |

| Washing, showering, bathing | 0.4 | 2.4 | Today every apartment has a shower or bathtub. |

| Wash & dry laundry | 0.4 | 1.2 | Fully automatic washing machines encourage frequent washing. |

| Exhalation & evaporation of the residents | 2.0 | 1.6 | Lower occupancy density of today's apartments. |

| watering plants | 1.6 | 2.1 | More house plants than before. |

| total | 6.0 | 8.5 | |

| Dehumidification through | Earlier | today | causes |

| Windows and doors | −3.0 | −0.5 | Joint sealing profiles prevent air exchange. |

| Open hearth, fireplace, stove | −3.0 | 0 | The negative pressure in the chimney ensured a constant flow of exhaust air. |

| Balance sheet | ± 0.0 | + 8.0 |

Differentiation according to structure

A distinction is made between central and decentralized ventilation systems and between retrofitted and new-build systems.

- Central systems have two outputs ( exhaust air that is led outside, supply air that is supplied to the living spaces) and two inputs ( outside air that is supplied from the outside, exhaust air that is extracted from the living spaces). Central systems are more complex, because the ventilation ducts have to be routed from the living rooms to the system:

- In the simpler variant, bedrooms and living rooms are connected to the supply air ducts, and the kitchen, bathroom and toilet to the exhaust air ducts. The rooms are connected by sound-absorbing overflow openings in doors or walls.

- In the more complex variant, each room can be regulated individually; each has its own supply air and exhaust air duct.

- Decentralized systems are particularly suitable for retrofitting individual rooms in which there are particular ventilation problems (e.g. bathroom, kitchen, toilet). It makes sense to use it, for example, in rooms with high humidity and thermal bridges on the outer wall, in kitchens or other rooms with regular high levels of air pollution, such as in smoking rooms. Since decentralized ventilation units are only installed in individual rooms, they are also suitable for retrofitting in existing buildings. Often they are installed next to the window or in the area of the window sill.

Decentralized systems work either with a small heat exchanger (cross- flow or cross- counter-flow heat exchanger as recuperator ) or with a regenerator (intermediate heat storage in a time-shifted counter-flow process). When using a regenerator, frost protection measures can be dispensed with down to approx. −15 ° C. The regenerator principle guarantees hygienic moisture recovery if a pore-free heat storage device is used. The heat recovery can be bypassed by simply switching the fans from reversing operation to permanent supply or exhaust air flow without the need for a bypass. Regenerators are usually used in pairs, either with one device each in two different rooms or with a double device to ventilate a single room.

Design and planning of controlled living space ventilation

The design of a controlled living space ventilation according to the promoted volume flow is necessary in order to guarantee a minimum air exchange in the rooms. The design is especially necessary for program- controlled systems, as they cannot measure the current pollutant concentrations in the rooms with sufficient accuracy or can not regulate the outside air supply . The aim of the design is to define a value that appears sufficient (or several values with coarse gradations) for the fresh air supply. These air volumes are then supplied to the rooms regardless of the actual situation. Newer systems work demand-oriented, for example by means of CO 2 control and / or moisture recovery, in order not to supply too large amounts of air, which can lead to the rooms drying out unnecessarily.

Around 30 m³ of air per person per hour are considered to be hygienically necessary. With four people permanently present, about 120 m³ would have to be exchanged per hour; With a living space of 200 m² and a building volume of 500 m³, this corresponds to an air exchange rate of 0.2–0.3 h −1 .

A minimum air exchange of 0.3 to 0.5 h −1 has proven useful for the design, i.e. a third to half of the air volume in a room can be exchanged per hour. The larger the usable living area and the lower the number of people present, the lower the minimum air exchange can be. If a system with geothermal heat exchangers is used for air conditioning in summer, higher air exchange rates should generally be aimed for. If the system is operated with too high an air change in winter, the air in the living spaces can dry out, which can be prevented by demand-oriented controls or moisture recovery.

There are different standards and recommendations for the design of controlled living space ventilation. These include ÖNORM H 6038: 2014, EN 15251, DIN 1946-6: 2009 (which, among other things, requires a ventilation concept ), SIA 382/1, as well as recommendations from the Passive House Institute or from comfortlüft.at.

Design of controlled living space ventilation according to ÖNORM H6038

In the ÖNORM H6038 three types of design are defined - the highest design is to be used:

- Room types

- Bathroom, also with toilet, require 40 m³ / h, separate toilet rooms 20 m³ / h, storage rooms 10 m³ / h, kitchenettes and kitchens 40 m³ / h. This means that controlled living space ventilation is not suitable for extractor fans.

- people

- The minimum outside air volume flow is 36 m³ / h per person

- Air exchange

- The required minimum air volume flow is calculated using the following formula:

Minimum air volume flow (in m³ / h) = usable living area (in m²) × clear room height (in meters) × minimum air exchange (the minimum air exchange should be 0.5 / h and for more than 150 m² living area it should be reduced to 0.3 / h may)

Building supervision guideline on the ventilation of windowless kitchens, bathrooms and toilet rooms, as of April 2009

The guideline in the version of April 1988 was introduced as technical building regulations in Bavaria with the announcement of the Bavarian State Ministry of the Interior on July 21, 1997.

The policy refers to the §43 para. 1 and 1 set 2 of Section 48 para. Model Building Code (MBO) of the windowless in homes kitchens, cooking niches, bathrooms and toilets ( windowless rooms ) are permissible only if an effective ventilation of these spaces is guaranteed.

For this purpose, every windowless room must be able to be ventilated directly by a mechanical ventilation system and have an air supply. In addition to the basic ventilation of the windowless rooms in kitchens, the ventilation system must also enable shock ventilation and be designed in such a way that no drafts arise in the apartment and no odors are transferred to other rooms.

| Windowless room | Air volume flow [m³ / h] | |

|---|---|---|

| Operation case A1 | Operation case B2 | |

| Kitchen: - basic ventilation - boost ventilation |

40 200 |

60 200 |

| kitchenette | 40 | 60 |

| Bathroom (also with toilet) | 40 | 60 |

| Toilet room | 20th | 30th |

Operating case A - Usage- independent operating time of at least 12 hours per day, intermittent ventilation must be possible.

Operating case B - usage-dependent operating time, boost ventilation must be possible.

Ventilation of bathrooms and toilet rooms without outside windows according to DIN 18017-3

DIN 18017-3 applies to the ventilation of windowless sanitary rooms in residential buildings as well as in buildings with residential-like use such as hotels, offices, tea kitchens, residential and old people's homes.

Ventilation systems for the ventilation of bathrooms (with / without toilet) are optionally designed for the following planned minimum exhaust air volume flows [q v ]:

- 40 m³ / h if the ventilation system runs continuously. If the air requirement is low (e.g. at night), the exhaust air flow can be reduced to 20 m³ / h, but no more than 12 hours a day.

- 60 m³ / h if the ventilation system is controlled as required during use. If the air requirement is low (e.g. at night), the exhaust air flow can be reduced to a daily average of 15 m³ / h. This does not apply to kitchens and kitchenettes. A fan downtime of up to one hour is permitted. The ventilation in the bathroom can be temporarily switched off if the bathroom is not being used to dry laundry or if there is another type of increased moisture exposure and the thermal insulation standard of the building meets the requirements of the 1995 Thermal Insulation Ordinance. A follow-up control must ensure that each time the ventilation unit is switched off, a further 15 m³ of air is removed.

The control as required can be implemented in windowless rooms by coupling the ventilation system to the lighting or otherwise by a humidity sensor.

For kitchenettes and kitchens with windows, the above-mentioned exhaust air volume flows apply accordingly (see also DIN 1946-6).

In the case of purely toilet rooms, the specified exhaust air volume flows may be halved.

In the case of windowless bathrooms and toilets, it can make sense to double the respective values.

If the ventilation system is also to take over the ventilation of the living and common rooms, details on the dimensioning and execution of DIN 1946-6 can be found. This also applies if a bonus regulation according to the EnEV is used.

Disturbance pressure

The necessary exhaust air volume flows must not change the influence of wind and thermal lift in vertical ventilation ducts by more than 15%.

It can be assumed that the static pressure between the ventilated rooms and the outlet openings in the building envelope increases or decreases by 40 Pa. If the exhaust air is routed horizontally, the interference pressure can be 60 Pa.

In the case of jointly used exhaust air ducts, the volume flow at the lowest unit should decrease by a maximum of 10% when all ventilation units are active.

Post-flow of outside air

The exhaust air from the room to be ventilated should be discharged as close as possible to the ceiling. The air flow extracted by the ventilation system must then be able to flow in through air gaps under the interior doors (approx. 1-3 cm wide) and then through leaks in the building envelope (infiltration). The proportion of outside air per unit of use can be determined on the basis of DIN 1946-6. In a building that is made airtight by today's standards, outside air outlets (ALD) are necessary in the building envelope (the number and size of which can be estimated using the tables specified in the standard) in order to be able to ensure adequate post-flow.

Ventilation lines

The exhaust air lines should be laid with a slope towards a point where any condensate that may develop can collect without causing damage. By insulating the lines in unheated rooms, the formation of condensation can be significantly reduced. Between the connection lines from the individual usage units, the main line should be routed vertically and without jumps or cross-section reductions, otherwise the line system must be calculated mathematically.

Non-return flaps, cleaning

openings , filters and fans After each ventilation device, a non-return valve must be provided so that odors and dust cannot be transferred to other units. If, in addition to the kitchen and bathroom, other rooms are connected within an apartment, further non-return valves are required. Check valves must close tightly at a pressure difference of less than 10 Pa. The leakage air volume flow must not exceed 0.01 m³ / h (10 l / h) with a pressure difference of 50 P.

Sufficient cleaning openings with a tight seal must be provided in the exhaust air lines so that the exhaust air lines can be easily cleaned at every point.

Filters should correspond to filter class G2 according to DIN EN 779.

It should be possible to see whether the fans are in operation.

Appendix B to DIN 18017-3 contains further information on maintaining the system.

Outside air preheating and heat recovery

If the ventilation system is not only used for hygienic purposes or for dehumidification, but is also to save energy, it is advisable to recover the thermal energy contained in the extracted indoor air.

For this purpose, various systems for heat recovery are used, which can achieve an efficiency of over 90%. As a rule, the principle can also be reversed in summer in order to then cool the air supplied to the building.

The geothermal energy , which is available free of charge, can be used for additional preheating of the outside air and to prevent passive heat exchangers from freezing , as the ground remains frost-free all year round from a depth of around 80 cm.

Passive heat exchangers

Passive heat exchangers generally do not require any auxiliary energy. Exhaust air and outside air flow through them simultaneously or one after the other in order to achieve a transfer of heat between the two air flows. With simultaneous flow, mostly only the "dry" heat energy is transferred recuperatively . With alternating flow through a storage mass, part of the contained air humidity is also transferred ( regeneratively ). The simple principle of alternating flow has led to mono-pipe ventilation devices in which the energy efficiency of the heat recovery is high, but the air quality is neglected. An explanation of the principle of high efficiency, even when maintaining air quality, can be found in the original patent specifications.

A geothermal heat exchanger can be connected upstream to preheat the outside air . This means that there is no need for an additional heating register , which is otherwise often used at outside temperatures below zero degrees in order to prevent the supply air temperature from dropping to below 18 ° C.

In the cold season, the humidity contained in the exhaust air condenses in the heat exchanger and has to be removed. At a certain outside air temperature, which depends on the system used, the condensate begins to freeze and blocks the heat exchanger. From this point on, the efficiency of the system is drastically reduced, as either the heat exchanger has to be bypassed or additional energy has to be used to warm up the heat exchanger. In particular, to avoid freezing, it is advisable to connect a geothermal heat exchanger upstream of the actual exhaust air / outside air heat exchanger.

Preheating can be achieved in a simple way by first leading the outside air through pipes to a depth of at least 1.2 m in the ground before it enters the building. For reasons of hygiene, it must be ensured that the pipes laid underground can be cleaned and that a slope is provided to avoid the accumulation of condensate.

A more hygienic and easier to lay alternative, but with greater technical effort and costs, are brine geothermal heat exchangers, in which brine pipes are laid in the ground instead of ventilation pipes. Brine refers to a mixture of water and antifreeze, which is transported by a circulation pump to a brine-air heat exchanger in order to release the thermal energy absorbed in the ground to the outside air.

The winter frost protection of the ventilation system can also be achieved through intermittent operation, provided it is not used to heat the building.

Sensitive people can choose a pollen and fine dust filter and moisture recovery as an option.

Active heat exchangers

With the help of a heat pump , a significantly larger amount of heat can be extracted from the discharged air flow or the ground. In doing so, these are cooled down or warmed up beyond the temperature of the outside air present if the heat pump is used to cool the outside air in summer.

The very low heating load of a passive house usually allows heating exclusively via the ventilation system. This is often done using a water-to-air heat exchanger, an electrical post-heating register or an integrated heat pump . The supply air must not be heated to more than 50 to 52 ° C, as otherwise there may be an odor nuisance due to the carbonization of dust. If the building needs too much heat, the ventilation volume flow would have to be increased to such an extent that there could be noise pollution, dry indoor air and drafts.

In a properly executed passive house, the hygienically advantageous air exchange rate of 0.4 h −1 is sufficient even at the lowest outside temperatures to supply the building with the required heating output. This air exchange rate means that a building with 1000 m³ volume to be ventilated would have to be supplied with a supply air volume flow of 400 m³ / h every hour.

advantages

- Through the use of heat recovery, the outside air is preheated by the exhaust air in winter and pre-cooled in summer. With heat recovery rates of 60–80%, the ventilation heat loss is only a fraction compared with window ventilation or operation without heat recovery (WRG).

- Filtered outside air with air filter ( fine dust , pollen, etc.)

- Removal of pollutants and odors (carbon dioxide, CO 2 , air humidity, evaporation, etc.)

- reduced risk of infection, improved ability to concentrate, avoidance of headaches and positive effect on the feeling of comfort

- Greatly reduced risk of mold growth in living space

- Inhibited dust mite growth

- In the event of external noise pollution, the windows can remain closed with a simultaneous supply of fresh air

- Cooling and slight dehumidification of the outside air in summer, as well as preheating of the air in winter with a geothermal heat exchanger - a KWL is not an air conditioning system , but it can slightly lower the room temperature in summer and dehumidify the supply air somewhat, which is perceived as very refreshing, - above all when there is humid summer weather, or when there are strong temperature fluctuations in winter

disadvantage

Previously, when there was a lack of ventilation, there were often problems with excessively high humidity and the possible occurrence of mold, but today indoor air with a relative humidity of less than 30% RH is observed in the winter months . The reason for this is that the cold outside air drawn in has a very low relative humidity after it has been heated. Humidifiers can be used against this; these bring moisture into the air through evaporation or evaporation. Technically more complex KWL systems contain air humidification. This can - just like evaporators on radiators - germinate microbes. There are also KWL systems that recover not only the heat but also the humidity, for example by means of enthalpy heat exchangers. (see also main article heat recovery )

If the sound insulation is inadequate or if it is operated at (too) high a level, the discharge of supply air from the outlet openings can cause drafts and / or flow noises.

- Regular maintenance of the filter system and at least the exhaust air lines are necessary

- For continuous operation, the power consumption of the respective system must be taken into account

- Although systems with an efficiency of over 90% are on the market today, the energy savings advertised are not necessarily given, because the heat losses can be higher at high air exchange rates compared to traditional window ventilation, which has an air exchange rate of 0.1-0.2 h −1 means in addition to the building leaks.

Fire protection

Depending on the federal state, from a building height of 6 - 7 m up to the upper edge of the floor on the top floor, requirements are placed on the fire resistance period of installation and ventilation shafts, ventilation devices and shut-off devices.

According to DIN 18017, shut-off devices (non-return flaps) with a fire protection jacket around the installation box of the ventilation device meet the fire protection requirements in ventilation systems for toilets or bathrooms if there is a height offset of 150 mm between the horizontally arranged non-return valve and the center of the junction of the connection line into the main line . In the event of a fire, the "cold air column" in the connection line of the ventilation devices protects the non-return valve from overheating, so that smoke and fire transmission to other rooms on the common main line is prevented.

Shut-off devices for kitchens, kitchenettes and systems in combination with toilets and bathrooms require an additional "active" shut-off by means of a spring-loaded metal flap with a fusible link or something similar.

Suitable shut-off devices must meet further criteria in addition to the requirements for fire dampers according to DIN 4102. Corresponding shut-off devices are marked with the addition “-18017” after the fire resistance period achieved (e.g. K90-18017). Details on use can be found in the building inspectorate approval, which u. a. May contain requirements for shaft walls, permissible line cross-sections and installation positions of the shut-off device.

If the shaft or wall cladding does not meet the fire protection requirements or has a cross-section greater than 1000 cm² (corresponds to a folded spiral-seam pipe NW 355 mm), classified ceiling bulkheads must be installed between the floors.

Joint operation with air-conditioned fireplaces in accordance with DIN 1946-6

The operation of the fan must not result in a negative pressure greater than 4 Pa in the user unit. This must be taken into account when dimensioning the outer wall outlets.

A joint operation of the ventilation system and open-air-dependent fireplace is only possible if a safety device with general building authority certificate of usability switches off the ventilation system or releases a sufficiently large opening to the outside if the negative pressure in the installation room of the fireplace exceeds 4 Pa. Otherwise it must be ensured that the ventilation system is not switched on when the fireplace is in operation.

Regulations

Germany

The term for domestic ventilation related standards are:

DIN V 18599 Energetic evaluation of buildings - calculation of the useful, final and primary energy requirements for heating, cooling, ventilation, domestic hot water and lighting:

- Part 1: General accounting procedures, terms, zoning and evaluation of energy sources

- Part 2: Useful energy demand for heating and cooling of building zones

- Part 3: Usable energy requirement for energetic air treatment

- Part 5: Final energy requirements of heating systems

- Part 6: Final energy demand of residential ventilation systems and air heating systems for residential construction

- Part 8: Useful and final energy requirements of water heating systems

DIN 1946 ventilation technology

- Part 6: Ventilation of apartments - General requirements, requirements for dimensioning, execution and marking, handover / acceptance (acceptance) and maintenance

DIN 4108 thermal insulation and energy saving in buildings

- Part 2: Minimum requirements for thermal protection

DIN Technical Report 4108-8 Thermal insulation and energy saving in buildings

- Part 8: Avoiding Mold Growth in Residential Buildings

DIN 4701 energetic evaluation of heating and ventilation systems

- Part 10: Heating, DHW heating, ventilation and supplement 1: System examples

DIN 4719 Ventilation of apartments - Requirements, performance tests and labeling of ventilation devices

DIN EN 12831 Heating systems in buildings - Method for calculating the standard heating load - National Annex NA

See also

- Kitchen exhaust

- Air types

- Air duct

- ventilation

- Ventilation concept

- Ventilation efficiency

- RAL assembly

- Hygiene guidelines for air conditioning systems and devices

literature

- Heinz-Jörn Moriske, Michael Wensing: Investigations into the indoor air hygienic situation in energetically renovated old buildings and in a passive house. In: Hazardous substances, keeping the air clean. Volume 67, No. 3, 2007, ISSN 0949-8036 , pp. 85-90.

- Nadja von Hahn: "Dry air" and its effects on health - results of a literature study. In: Hazardous substances - keeping the air clean. Volume 67, No. 3, 2007, ISSN 0949-8036 , pp. 103-107 ( dguv.de PDF; 104 kB).

- Rolf Schmidt: What kind of heating does the house need? - Systems of heating and ventilation technology in comparison. 2010 ( irb.fraunhofer.de ).

- Andreas Greml, Ernst Blümel, Roland Kapferer, Wolfgang Leitzinger: Final report: Technical status of living space ventilation. Evaluation of existing living space ventilation systems with regard to their technical quality and practicality. 2004 ( xn-- Komfortlftung-3ob.at PDF; 8.1 MB).

Web links

- Information about comfort ventilation, Austria

- Independent Swiss device comparison according to energy efficiency, hygiene class, sound class

- Information on funding programs and information about comfort ventilation with heat recovery (KWL)

- Comparison of central and decentralized air conditioning systems - decision criteria

- Planning a KWL

- Planning tool for controlled apartment ventilation according to DIN 1946-6 or DIN 18017-3 (Excel format), LIMOT GmbH & Co.

- Ventilate properly: Tips from Stiftung Warentest . In: test.de . May 17, 2010 (accessed February 1, 2013)

- Home ventilation systems on energiesparhaus.at

- European test center for home ventilation devices

- Information portal of energieagentur.nrw

- Federal Association for Residential Ventilation eV

- Humidity calculator Calculates state variables and other data for humid air. Up to 4 air samples / air conditions can be displayed in parallel.

- Calculator for home ventilation and indoor climate Calculates the enthalpy and moisture flow from air condition data, moisture sources and volume flows. With Mollier hx diagram including air pressure adjustment .

- Ventilation of apartments (PDF; 651 kB) The uses of the standards DIN 1946-6 and DIN 18017-3 / TÜV SÜD Industrie Service GmbH, Munich

Individual evidence

- ↑ Controlled domestic ventilation . In: kwl-info.de .

- ↑ Interconnection Consulting : The market for industrial and commercial ventilation defies the building lull. ( Memento of the original from February 24, 2016 in the Internet Archive ) Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice. February 2, 2016.

- ↑ Bauforum: Tough price war for living space ventilation. June 15, 2015.

- ↑ a b Roland Wenzel engineer for air and refrigeration technology: Seminar on controlled living space ventilation. (PDF) Umweltzentrum.de, accessed in February 2016

- ↑ Hessian Ministry for the Environment, Energy, Agriculture and Consumer Protection - Controlled Residential Ventilation (PDF; 1.4 MB)

- ↑ Air volume recommendations ( Memento of the original from August 10, 2013 in the Internet Archive ) Info: The archive link has been inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice. . In: Komfortlektiven.at . October 15, 2010.

- ↑ Questions and answers on DIN 18017-3 , Federal Association for Residential Ventilation eV, 2018

- ↑ a b c Chapter 2 ( Memento of the original from March 4, 2016 in the Internet Archive ) Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice. of the planning folder of LIMOT GmbH & Co., Bad Mergentheim, accessed in February 2016

- ↑ Patent 2007 ventilation system with heat exchanger .

- ↑ Patent 2020 Decentralized ventilation system with heat exchanger .

- ↑ Passive House definition . In: passipedia.de . accessed August 1, 2013.

- ↑ Project planning of passive houses ( Memento of the original from August 10, 2013 in the Internet Archive ) Info: The archive link was automatically inserted and not yet checked. Please check the original and archive link according to the instructions and then remove this notice. (PDF; 4.8MB), p. 12, from Dietmar Kraus, University of Munich, accessed August 1, 2013.

- ↑ Dr. Rolf BOOS et al .: Assessment of indoor air - physical factors - carbon dioxide as a ventilation parameter . (PDF) Retrieved January 17, 2017 .

- ↑ CO2 - the most important indicator of air quality. In: pluggit.com. Retrieved November 7, 2016 .

- ↑ baunormenlexikon DIN - German Institute for Standardization eV In: www.baunormenlexikon.de , accessed on August 3, 2013.

- ↑ Dr. Thomas Hartmann: DIN 18599-6 is being expanded. ( Memento of the original from January 5, 2012 in the Internet Archive ) Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice. In: VFW - Federal Association for Apartment Ventilation eV, specialist magazine for residential ventilation. Edition July 2011.