Peeling mill

In a peeling mill , the grains spelled , barley , oats , millet and rice are peeled, that is, the husks that are firmly attached to the grain and that do not fall off during threshing are removed (peeling). The husks are indigestible for the human organism and would negatively affect the taste and chewing impressions.

In addition, the peeled grains are usually rolled ( oat flakes ), cut ( groats ) or polished ( rice , barley ) in a peeling mill . Other possible processing steps are mostly identical to those in a grain mill .

history

Peldemühle is a historical expression for a peeling mill, used in particular in northern Germany and the Netherlands. Most so are certain types of mills ( windmills , water mills , motor mills) for Pelden , that is peeling from rice or barley to barley or grits meant. The Low German or Dutch verb pelden is related to the High German verb pellen , which has the same meaning. Wind and water mills were as pure Peldemühlen with one or more Peldegängen ( Pellgänge , Graupengänge or in southern Germany also Gerbgänge called) equipped or "mixed" as mills with Pelde-, grinding and / or shot transitions combined. In the peldegang the specially hewn peldestones ran at a greater distance from each other so as not to grind the grains. Peldewindmühlen were particularly popular in northern Germany for the production of barley; rice was preferably peeled in large motorized rice mills. The Wittmunder Peldemühle from 1741 is Germany's oldest gallery Dutch windmill .

Processing principles in peeling milling

The formerly used "lower runner peeling process" (tanning process) has been completely replaced in modern milling by rubber roller peelers (rice) or impact peelers (oats, buckwheat, sunflower seeds). With the help of "plan separators" (table separators or paddy separators, originally developed for the selection of peeled rice or oats from the core mixture), light and heavy material fractions are separated from one another. The husked grains can then be rolled flat directly on a flaking chair or they are cut into coarse, medium or fine groats beforehand with a “drum groats cutter” . This is mainly done with oat or barley grains.

- Rice is peeled and possibly polished (possibly also glazed) and, depending on the desired product, also parboiled . Rice flour is also made.

- Other cereals (mainly oats, barley, spelled) are peeled off

- Legumes , roots , tubers and nuts are processed.

Manufacture of flakes

Cereal flakes are edible whole grain products. The flakes are made with a flake chair (also: flake chair). The smooth rollers contained (diameter: 400–600 mm) squeeze the grains and roll them out. Flaking is usually preceded by heat or steam treatment, which guarantees good deformability of the grains and promotes starch digestion. Cereal flakes made from oats, spelled, barley, rye, wheat or buckwheat are components of many mueslis . Depending on the starting product, a distinction is made between the following types of flakes (see also oat flakes ):

- Large leaf flakes made from whole grains

- Small leaf flakes from grated (cut) grains

- Instant flakes made from whole wheat flour

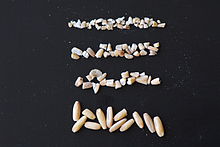

Production of pearl barley and groats

- Pearl barley are round grains of grain (primarily barley) that have been freed from the seedling and shell layers (fruit and seed peel).

- Pearl barley are especially small, rounded barley. For this purpose, the barley grains are cut into parts (scooped) beforehand.

- As groats referred to coarsely crushed cereal grains, mainly oats and barley. Wheat, rye, green spelled and buckwheat grains are also processed into grits. Grits are offered in coarse, medium and fine grain sizes. The grinding takes place on a "groats cutter". Grits are mostly used as a soup or cooked to a pulp.

Web links

Individual evidence

- ↑ P. Erling (Ed.): Manual flour and peeling mill . AgriMedia, ISBN 3-86037-230-0 .

- ↑ Wilfried Seibel (Ed.): Warenkunde grain . AgriMedia, Bergen / Dumme 2005, ISBN 3-86037-257-2 .