Windmill

The windmill is a technical structure that with its the wind being rotated wings work done. The most widespread use was as a mill , which is why the name is transferred to all such systems.

In the history of energy conversion , windmills are the only early power machines alongside the water-powered water mills, after the muscle power machine and until the invention of motors . Their use as a grinding mill , an oil mill , for processing materials (e.g. as a sawmill ) and as a pumping or pumping station (see article wind pump ) was correspondingly diverse . The classic windmill with rectangular, elongated blades is common in Europe both in the flatlands of the northern regions and on the sea coast in the Mediterranean area. Today's wind turbines are the successors to windmills.

In some regions of Asia and Europe , windmills were the most powerful engines of the pre-industrial era. They were especially important in dry and windy areas such as B. the Middle East , Greece and Portugal and in the lowlands where water wheels could not be used such as the Netherlands , Denmark and parts of England . These regions also include the flat western Schleswig-Holstein and parts of northern Lower Saxony .

history

Early investments

The history of the windmills is not completely secured and the research is very problematic due to the difficult source situation. Precise information about the age of the windmills was as little available as of 1995 as about their exact origin; a problem that Heymann also saw as very difficult to solve in the future. The standard work on windmills is the work by Notebaart, published in 1972, which described the state of research as "inadequate".

Written records from the Codex Hammurapi indicate that the first windmills were built more than 4000 years ago. Hau gives evidence of Egyptian windmills with an estimated age of around 3000 years, but admits at the same time that there is no high-quality evidence that ancient peoples such as Egyptians, Phoenicians, Greeks and Romans actually knew windmills. There are also reports of an organ powered by a wind turbine. It is said to come from the Greek inventor Heron of Alexandria , who lived in the 1st century AD. These early systems are undisputed. This is what the Italian economic historian Malanima calls z. B. the first known evidence for the existence of windmills is an early medieval written source from the first half of the 7th century AD.

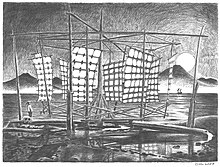

Persian windmills , which differ from the occidental design in that they have a vertical axis of rotation and vertical blades, blades or sails, were in use in eastern Persia in the 9th century, according to Islamic geographers. Another type of windmill with a vertical axis of rotation is known as a Chinese windmill or a Chinese wind turbine (see also folding-wing rotor ). It is unclear whether these turbines are older than the Persian wind turbines and whether the European turbines are possibly derived from the Chinese turbines.

The technology of the Chinese version differs significantly from that of the Persian windmill, because it uses free-standing sails that are automatically aligned with the wind without any walling. The European form of these so-called junk sails is known as lug sails . The Persian mill with mats or slats on the rotor, which are arranged like the blades on the wheel of a paddle steamer, must be walled in in an open semicircle, because there the sail surfaces are directly rigidly connected to the axis of rotation and do not align themselves optimally with the wind on their circular path can. Therefore, a half-open walling covers the part of the rotor where the blades would otherwise have to turn against the wind with a braking effect. The aerodynamic function of the rotor on the Persian windmill is called a drag rotor . The Chinese windmill, on the other hand, is a boom .

High and late Middle Ages

Arab windmills came to the Iberian Peninsula with the spread of Islam and were improved there.

Windmills with a horizontally positioned rotor axis have been documented in Flanders , Southeast England and Normandy from 1180 onwards. They are probably an independent European development. Technically, this system and another system, which is believed to have been built in Brabant at the beginning of the 12th century, was a post mill , a type in which the entire mill house was turned into the wind. This type quickly spread to northern and eastern Europe. One of the earliest depictions of a windmill is a copy of Aristotle's scientific work . It dates from the 3rd quarter of the 13th century.

In addition to water mills, the windmills were used in many ways. The water mills were primarily used on the watercourses in the low mountain range, while the windmills in the plains were in sufficiently windy places.

Mills were long under the mill ban of the respective sovereigns. The population was forced to visit the so-called Bannmühle to have their grain milled there. In connection with a bad road network, this practice led to local economic cycles in which the mills played an important role. When the ban was lifted, the population was able to choose their preferred mill themselves and thus stimulate competition and thus technical development.

Modern times

At the end of the 16th century, the Dutch windmills appeared in the Netherlands , in which only the tower hood rotates. From the Middle Ages to the end of the 18th century, windmills were widespread across Europe in immense numbers. Engravings and woodcuts from the Middle Ages and modern times clearly show their distribution. They were mainly to be found north of the low mountain range in the windy northern European lowlands, in large parts of France , the Benelux countries with a focus on the Netherlands as a coastal country (which once had 10,000 windmills), Great Britain, Poland, the Baltic States, northern Russia and Scandinavia. There are also a few windmills in southern Europe (Portugal, Spain, France, Italy, the Balkans and Greece). The typical tower windmills with a flat conical roof and mostly fixed cap were found here, be it with sail gate wings similar to those in Central Europe or sail pole wings with drawn-up triangular sails.

After the freedom of trade was introduced in Prussia in the first half of the 19th century, there was a significant upswing in the windmill industry. With the number of independent masters, the number of windmills rose by leaps and bounds. At that time the windmills were also common in the mountainous, southern parts of the country. For example in the Neuwied Basin , on the windy hills of the southern low mountain range. A colder climatic period that led to increased winds helped them at these locations (see Little Ice Age ). A growing number of windmills in the 19th century is also documented for the Saxony-Thuringia area.

According to censuses by the Prussian government, 18,362 windmills and 54,529 water mills were still in operation in the German Empire in 1895, of which 97% of the former and almost 60% of the latter were grain mills . At that time there were 58,530 companies that worked with steam power. Although the steam engine was successfully used for the first time at the beginning of the 18th century, it was not finally established until the second half of the 19th century. The development of the steam engine in the 19th century slowly broke the dominance of machines powered by water power and wind energy. Since the operation of the windmills was dependent on the weather and did not achieve the performance of large steam engines, the use of the steam engine was more practical, especially for large companies, despite the often higher costs, and the number of windmills fell sharply. The so-called “first mill death” began. The conversion to electric drive was offered for the still existing windmills in order to secure the existence of the small and medium-sized enterprises. In 1936, for example, a mill with an electric drive was shown at an exhibition in Berlin.

During and after the Second World War , the still existing windmills experienced a brief heyday, as there were no alternatives to provide the required machine performance due to a lack of fuel, electrical energy and intact drive machines. This upswing came to an end in the Federal Republic of Germany in the 1950s, primarily due to the Milling Act , with which large companies got rid of the unpleasant competition from windmills with premiums for shutdown ("second mill death"). As a result, the number of commercially operated windmills decreased dramatically.

restoration

In the 1980s, a wave of restorations developed in West Germany due to the rediscovery of the old cultural technique. Many windmills have been brought back to life as technical or manufacturing monuments. Other uses as a museum, as a restaurant, as a club mill for the maintenance of village images or for residential purposes were implemented. The technical restoration that was carried out was not always correct and was supported by many improvisations, as the job of mill builder was removed from the trade register in the 1950s under the mill law .

In East Germany, collectivization reduced the number of privately operated mills. After the reunification of Germany in 1990, the many small mills still in existence could not hold their own against the new competition and went out as commercial mills. Today there are around 1,400 wind and water mills in reunified Germany that take part in the German Milling Day at Whitsun every year .

By the end of the 19th century, there were more than 10,000 windmills in use in the Netherlands , but their number has now shrunk to around 1,000. In the USA around 1880 around six million wind turbines were supposed to have been in use for pumping water, at the beginning of the 21st century there were only 15,000.

function

From a technical point of view, a windmill is a device that uses the kinetic energy contained in the wind as mechanical energy. For this purpose, windmills take the energy with their wings from the wind and convert it into rotational energy . To do this, the wings have to be turned into the wind so that it can blow on the wings from the front and they are set in motion. The rotational energy obtained in this way is fed into the mill building via a vane shaft.

A large comb or gear wheel sits on this shaft, which is slightly raised at the front. The energy is taken from this in a first transmission with a working shaft and directed downwards into the building. With this rotating shaft, the energy is now in the building and can now be used for mechanical work.

In post mills this is usually done directly with a basket wheel on the grinding gear , in Dutch windmills the energy is first fed downwards from the rotating cap into the fixed mill building via a vertical shaft . There the grinding gear is driven with a basket wheel via a further gear stage. When the mill is used for other purposes, the rotating shafts can take the energy to operate the machines required in the mill by means of gear wheels, grinding and friction disks or flat belts. Depending on the design of the windmill as a grinding, ramming, hammer, sawmill or other applications, these are different machines.

In contrast to this, there were also windmills with a vertical axis of rotation and vertical blades, blades or sails that revolved on a horizontal plane of rotation. They usually have the point of take-off of the rotational energy from the vertical rotor and main shaft at the bottom of the rotor's floor bearing. There you will find the equipment appropriate for the intended use, such as a millstone or a lifting device for irrigating fields. As a historical windmill, these systems only existed in the Oriental and Asian regions.

application areas

Windmills were used in various areas of activity: In addition to grinding grain and other materials, they played an important role as wind pumps, e.g. B. in irrigation and drainage.

Originally, windmills were used as grain mills for grinding (grinding and grinding) grain, peeling ( pelden ) barley ( barley ) and rice . In particular, grinding and peeling in small quantities on the grating stone was a daily, exhausting work that could now be made more effective and energy-saving with the help of the windmills. Grinding and crushing was later extended to other materials - oil, mustard , spice , color (crushing and mixing minerals and earth ), crushed stone, powder , gypsum , chalk, snuff mills , and further threshing mills were created , Chaff mills , tinder mills , in which oak bark was pounded to obtain tannic acid for the leather industry . There were also other material processing applications such as grinding mills , saw and hammer mills for wood and metal, since the 14th century lathe mills, later drill mills (pipes), wire drawing mills , roller mills and cutting mills for sheet metal processing. In the 16th century, more than forty mill-operated manufacturing processes were known in Europe.

In the coastal areas of the Netherlands, windmills were used as scoop and pump mills for drainage from 1394 and used the long-known principle of the Archimedean screw . This raised the water from the polders over the dams in several stages and drained the diked areas. The drainage of low-lying areas was the most important application in the Netherlands. In East and North Friesland they were used for draining (“dry grinding”) peatlands. Another pumping application was the lifting of brine to sprinkle graduation towers (spa treatment and brine concentration for salt extraction). Mills were also used for ventilation .

The German Society for Milling and Milling Conservation (DGM) has compiled a compilation of 150 different mechanical activities on the use of windmills, from A for pump mill to Z for twist mill.

Locations

Wind and water mills were not located in the village like treadmills . Their locations were in places that were particularly exposed to wind or where hydropower was available. Since millers mostly lived at or near their place of work, the place of business and apartment were mostly outside the village . Windmüller had no regular working hours . With the right wind, they put the mill into operation at all times of the day and night and also on weekends. This situation made them suspicious to the villagers. When guilds were founded in the 18th century , the wind millers only managed to overcome these prejudices very late and to form their own guild.

As for some purposes such as If, for example, individual mills were not sufficient for drainage, windmills were set up in a concentrated manner in some areas, which can be considered the forerunners of modern wind farms .

European windmill types by design

With the increasing technical development, several types of windmills emerged in Europe, which differ in their design. The new developments initially spread regionally - always strongly influenced by the respective mill builder - and only in the course of time did they spread beyond the region. Due to the local peculiarities, there were always special shapes such as a coker windmill with a gallery.

Flutter

The flutter mill or the flutter , derived from fries. Fletta = to move (ndl. Tjasker ), is the simplest and smallest type of windmill and is used for vertical water transport and drainage.

This mill was invented in the Netherlands in the 16th century, where it was used for poldering and in East Friesland for draining wetlands. In the middle of the 20th century it had almost disappeared due to modern pumping stations. Today in northern Germany there are again a handful in museums and in use for re- humidifying biotopes . There are still 25 of these mills in the north of the Netherlands, 11 of them in Friesland .

The flutter essentially consists of an Archimedean screw and a small wind wing cross (1.5 m - 7 m) with board or sail gate wings. This sits directly at the upper end of the Archimedean screw; directly at the corrugating head behind the wings supporting a small block at an angle of about 30 ° the device. The lower end of the Archimedean screw protrudes into the moat from which the water is to be lifted and directed to the outside. It is turned into the wind by hand . Because they were small and light, these mills could be easily moved when the water was pumped out of the trench or drainage was no longer necessary in a region. These mills were most common in the Netherlands (North Holland, Friesland) and in the lowlands in East Friesland. In Germany, flutters are now in Riepe , Bedekaspel , Weenermoor and in Grotegaste in East Frisia. In the Netherlands they are still widespread in the polder regions.

Post mill

The oldest type of windmill in Europe is the post mill . It can be proven in Europe since the 12th century. Initially known in the region of Belgium and northern France, it spread over time over the whole of northern Europe to the Baltic States, where it was mainly found in windy northern Germany. That is why it was given the name Deutsche Windmühle there .

With this type of mill, the whole building including its partly heavy machinery is rotatably mounted on a trestle. This supports the vertical, mostly round mill or house tree, which protrudes into the middle of the mill building and on the upper end of which the transverse four-sided flour bar, also known as a hammer, is rotatably mounted. The load is transferred to the house tree via the tenon and the saddle under the building. Both are made of wood and need constant maintenance (lubrication, stability control). The entire stiffened mill box is suspended from this rotatable construction.

To support the rotation , the stable codend (Low German for "tail", control bar on the back of the mill box) is attached under the building at the rear, which acts as a lever and supports the rotation. English post mills in many places had a large wind rose on a wheel-supported suspension with access stairs instead of the codend construction, also attached to the rear. The trestle was mostly surrounded by a mostly round stone building (Rundbau, English roundhouse ).

Depending on the year of construction, location and mill builder, the miller's house has a mostly rectangular, sometimes more square, floor plan. The heights of the mills are also designed differently, as is the position of the stairs at the rear. The roof is usually designed as a gable roof .

The pivot bearing is therefore under the mill building. This means that the entire building with the machines always has to follow the wind. To support this, pegs were often rammed into the ground around the mill and the mill was pulled around using a pulley system that was clamped between the piles and the codend.

Since the entire mill was constructed of wood, it could be dismantled and rebuilt in another location. This was particularly important during times of war, but also because of the increasing need for space in cities due to population growth . Many windmills that had previously been in a good wind spot became windless as the development in the vicinity increased and the wind took the wind away from the windmills. As a result, many mills were dismantled and rebuilt in more wind-friendly locations.

The different structural design of the trestle made it possible to gain additional storage space . In addition, these types of mills were often given pockets on the side of the building box in order to get more space for machines in the building. The tallest post mill ("De Meerlaan", now a ruin) can be found in Gistel , West Flanders: Its substructure is a 15 m high, five-storey stone tower with a gallery below the 5th floor - a kind of tower gallery mill.

Coker or quiver windmill

A further development was the coker windmill , also known as the Wippmühle . It emerged from the post mill by drilling through the house tree and leading the vertical shaft straight through into the newly created lower part of the mill. The transfer of the energy from the mill box to the non-rotating lower part then took place via this vertical vertical shaft. The mill itself rotated around its vertical shaft, mounted on the " quiver " (Niederdt./ndl. Koker ) called, cylindrical bushing of the shaft made of oak, which connected both parts of the building. The turning level was at the upper end of the quiver - analogous to the tenon of the house tree of a post mill. The quiver was therefore also a support and turning area for the mill box as a house tree replacement. At the lower end of the shaft, in the lower building, originally the open beam support structure of the coker and thus the mill, the transfer was first made to an Archimedean screw, because the first coke mills were used as scoop mills.

In the case of grain mills, sawmills, etc. of this type, the grinder / sawmill and all the machines from the former post mill building were moved to the lower solid substructure made of wood or masonry. In the mill case, only the primary drive mechanism (wing cross, main shaft with comb wheel) and the upper end of the upright shaft required for power transmission and equipped with a bunker ( crown wheel ) at the top remained. So it turned, just like the post mill, but the mill house, which is much smaller here. In addition to the main mechanism, all other parts have been moved from the mill box to the fixed lower part.

These mills were mostly smaller than post mills and were mainly used for pumping purposes or to provide smaller outputs . In Walbeck this type exists as only mill in NRW a larger specimen of a former Dutch Saw Kokermühle (1780) as a grain mill (1823) with an octagonal, conical above the ground floor tapering stone foundation. In Northern Germany, there are still a few copies of the formerly widespread coke mill, such as the Schöpf coke mill in Ihlow-Riepe, the rare gallery coke mill (grain mill) in Edewecht as a copy and original in the Cloppenburg open-air museum , the museum village of Cloppenburg , and the coke mill on the new graduation house in Bad Rothenfelde , which was used to transport the brine over the graduation house.

The structurally smaller versions of this mill are called Spinnkopfmühle (Niederdt. Spinnkoppmöhl / ndl. Spinnenkopmolen ).

Tower windmills

A tower windmill (Dutch language: torenmolen) is a tower built from brick or natural stone with a gearbox built into the roof cap, grinder in the tower building and attached wing cross, as they have been on castle walls, fortifications and city fortifications since the 13th and 14th centuries ( Bottmühle , Cologne ; Wijk bij Duurstede , Netherlands). In these early examples, the blades could not be rotated in a different wind direction and had to be attached to the mill tower in the main wind direction during construction. In Europe, this type has been known as its own type since the 14th century, mainly in the region around the Mediterranean . Simple gears , later also vertical shafts, transferred the energy to the inside of the building to the grinder.

There is also the tower windmill of the Dutch type with a rotatable cap ("Turmholländerwindmühle"). It also has a cylindrical, stone-walled mill tower, sometimes slightly conical, similar to the tower windmill with a fixed cap, but often more compact. Its origins go back to the 15th century. It was widespread in Western Europe (West Germany, France, the Netherlands, England). In the southern Netherlands, four functioning tower windmills have survived as grain mills, some from the early days of this type of mill, three in the province of Gelderland in Lienden (1644), Zeddam (1441) and Zevenaar (1408) and a fourth in Maastricht- Gronsveld (1623 ). Similarly, there was in Germany ( North Rhine-Westphalia ), including in the district Heinsberg in Heinsberg district church Hoven , in the forest moist district hair and Gangelt district Breberen where three still fully functioning Tower Dutchman stand. In addition to many non-functioning tower mills, Walbeck (Geldern) also knows the “Steprath Mill” as the oldest functioning German windmill. They also existed in England and France. These mills were mainly found in the Rhineland, Westphalia and eastern Germany (Mecklenburg, Saxony, Saxony-Anhalt).

The term "tower windmill" is sometimes extended to conically built stone Dutch mills (as gallery, mountain, earth Dutch) (especially in England). Such mills are never called “torenmolens” in the Netherlands, but always “ronde stenen (rondstenen)” stellingmolens (Galeriem.) / Beltmolens (Bergm.) / Bovenkruiers (top-turning) / grondzeilers (basic sailors).

As Bärwindmühlen tower windmills particularly massively executed are designated, the tower as a defense tower is integrated into a city, castle or other fortification wall or is placed on such a defense tower. The tower of such a fortified mill had to be correspondingly thick-walled in order to be able to withstand attacks with heavy projectiles. The name is derived from the tower shape, which is vaguely reminiscent of the stocky stature of a bear . Separately standing tower windmills, which are not integrated into a fortress wall, but are built in the manner of a defensive tower (ie with a massive brick tower), are also called "bears" less often. Several such mills have been preserved in the Lower Rhine region .

A tower windmill, unique in the world, is located near the village of the same name in Chesterton in Warwickshire , England, the Chesterton windmill with an arcade base and internal harvester.

Dutch windmill

At the beginning of the 16th century, the Dutch windmill , also known as the cap windmill, was invented in the Netherlands . This type is mostly an octagonal (to twelve-sided) wooden structure on a solid foundation, in which only the upper cap can be rotated with a codend (a bar system at the end of the hood for turning the cap) or the compass rose . Thanks to the high revolving level, the whole building could be made larger and more stable. Larger wing crosses were thus also possible and thus a significantly higher output (up to 30 kW ). In northern Germany there are some octagonal windmills in wood construction (rarely in all-stone construction) with an also octagonal, up to six-story brick substructure (base, including gallery floor) of enormous height. Examples are the Hager windmill in Hage near Aurich (Germany's highest windmill with a cap height of 30.2 m), the Vareler windmill (Germany's second highest windmill with a cap height of over 29.8 m) and the Amanda windmill in Kappeln (stone octagon with five floors including a gallery on a four-story, square stone base), the highest windmill in Schleswig-Holstein with a height of 29 m.

Due to the significantly greater height of the Dutch windmills, it was no longer possible to reach the wings or the codend. Therefore a kind of balcony, a circumferential gallery (ndl. Stelling ), was attached around the mill, from which both the wings and the codend could be operated. These types are called Galerieholländer (ndl. Stelling molen ) (example: Britzer Mühle & Mühle Aurora in Jork). The highest mills of this type and also in the world are the De Nolet (2006; 43 m cap height) and De Noord (1807; 33.5 m cap height) in Schiedam , both conical stone windmills. Another possibility to build the impeller higher was achieved by pouring earth on which the building was to stand - a partially accessible wall was created around the mill. These types are called Berg- or Wallholländer (ndl. Bergmolen or beltmolen ).

Dutch mills built at ground level are called Erdholländermühlen (Erdholländer), which in the Netherlands are called grondzeiler (German " Grundsegler ") or bovenkruier (see "wing tracking"), as the wings reach almost to the ground. Such mills are located in areas without wind obstruction (North Holland, East Frisia).

With a higher filling, a passage through the wall and the mill foundation could be built. This special form is called drive- through Dutch , where you could drive a cart or tractor into the mill base on one side and back out on the other. In the middle of the passage, quasi in the mill cellar, the flour or grain sacks were then loaded and unloaded with the mill's own hoist (example: Grottenherten windmill ). In principle, mill types (depending on the drive and housing) can be combined: a gallery dutchman on a high embankment as a gallery driveway dutchman. A rare special form is the roof dutch , which is placed on an existing building or a water mill.

With very few exceptions, Dutch windmills conduct their energy into the building by means of a vertical shaft. For this purpose, the blades are connected via the blade shaft up to the vertical shaft running vertically through the building and are connected directly via gear wheels. This cannot be separated during normal operation, so that when the sashes are rotating, the energy in the building can be taken from the rotating vertical shaft and distributed to the connected machines. The Dutch windmill spread very widely in Northern Europe. Only the high construction costs impaired their spread.

Paltrock windmill

A parallel development to the Dutch windmill was the Paltrock windmill . It is a complete building that is turned into the wind on a pulley at ground level. This turns the whole building into the wind and not just the wings with the cap, as with the Dutch windmill. In Germany, it was often converted from a post windmill by removing the bracket and placing the building on the aforementioned roller ring. Paltrock windmills were mostly cheaper than the Dutch windmills with almost the same efficiency. The name is derived from the similarity of the mill building with the coat-like robe of Palatinate immigrants to the Netherlands, the "Pfalzrock" (Niederdt. Palzrock / ndl. Paltrok ). Over the years, the word was ground to "Paltrock" (Lower German) / "Paltrok" (Dutch). The derivation "Paltrock = Faltrock", which can sometimes be read, is wrong. The folded skirt is called "plooirok" in Dutch.

Special forms

Some mill builders not only rely on one form of energy, but also combined water power with wind power. So-called wind water mills were built . They stood by a stream from which the energy was drawn by a water mill. If the location promised enough wind, this was supplemented by an attached windmill. The power was transferred to the same vertical shaft, which, depending on the circumstances, was driven either by the wind or the base load by the water energy. There are very few mills left of this type of windmill. In addition to the one in Hüvener Mühle in Emsland , this includes the monastery mill in Lahde on the Westphalian Mühlenstrasse in the Minden-Lübbecke district .

Another, but not uncommon, special form of a windmill is that of the Westernmill , which was widespread millions of times in the United States of America at the beginning of the twentieth century and was mostly used in island operation on farms for grain grinding rather than for pumping water or even for generating electricity . With this type of construction, the name windmill is less common, probably because of the different main uses and the construction method in which the mill building was replaced by a simple lattice construction. Because of the typical appearance with a large number of wings, this shape is also called the American wind rose or just wind turbine.

The barn windmill in Saalow , which was built near Dresden in the 19th century, is almost unique worldwide . It is designed in such a way that the wind that drives the blades flows directly through the building.

Wing types

Windmills are wind power machines, which means that they get their energy from the wind through the mill blades. The wings are inclined surfaces that are exposed to the wind pressure perpendicular to their plane of rotation in such a way that they give way to the side and convert the wind pressure into a circular movement on their axis of rotation. This is superimposed by the lift on the wing as the turning speed increases. The inner circular path in the vicinity of the axis turns more slowly over the wing length than the outer one at the wing tips. Accordingly, the inclined surface of a wing must be inclined at different angles to the wind.

Windmills work on the principle of buoyancy . Therefore, the angle of attack of the wing to the incoming air determines the efficiency of the drive. Since the wing moves faster on the outside than near the axis, the profile there must be set flatter than further inside.

A wing consists of a rod made of wood or metal and the wing surface, which is divided into two parts of different widths by the rod. The narrower part in the direction of movement is called the breastplate or front hedge. It is only half as wide as the rear end or hedge. So-called logs are stuck through every 30 to 50 cm across the rod, which are closed off by the seam slats.

The plane at right angles to the wing shaft in which the wings rotate, i.e. their turning circle plane, is called the wind plane . Everything in front of it is called before the wind , everything behind it is called under the wind . In the most common four-bladed windmills, two rods are inserted into the corrugated wing head at right angles to each other as a pair of rods . The outer pair of rods or wings are field rods, the inner pair facing the mill building are house rods. Windmills almost always turn clockwise, viewed from the miller in the mill (under the wind) , the few that turn counterclockwise are therefore often called “false mills”. An example of a "left-handed man" is the five-bladed, five-story tower windmill Dobson (Dobson's Mill) in Burgh le Marsh , Lincolnshire , England.

Five-bladed windmills, not uncommon in eastern Germany in the 19th century, have hardly been preserved. There are not the windmill Wendhausen in the district Wendhausen the community teaching (Germany's only remaining wind and mahlgängige five-bladed windmill) and the mills in Naumburg (desolate state without wings and gallery) Flechtingen (burnt mill stump) and the propaganda mill in Hetzwalde . Worth mentioning are the Liebemühle Obercunnersdorf and the Malliss windmill , 1875–1948.

Because of the odd number of blades, these mills require a special five-pointed corrugated head made of metal with five rectangular sleeves into which the individual rods are inserted and fastened, or other suitable fastening devices. Six-wing windmills, rare in Germany (Kütermühle in Kiel , demolished in 1927 after a fire). The Schönbacher Mühle was a rare ten-wing Dutch windmill from 1899 to 1932. In England, windmills with multiple wings - five, six or eight-winged - were not uncommon. There were quite a few in the 19th century

- five-wing mills (Alford, Dobson, Maud Foster),

- six-bladed mills (Sibsey, Heage, Waltham)

- eight-wing mills (Skirbeck / Boston, Holbeach / South Holland, Market Rasen / West Lindsey, Leachsche Mühle / Wisbech , Heckington / North Kesteven as the only ones still in existence today) have or had a six-ray or eight-ray corrugated head.

In England, the engineer developed John Smeaton the named because of its distribution in the county of Lincolnshire cast iron Lincolnshire Cross (Engl. Lincolnshire Cross ). As with the five-winged mill, all the wings are on one level. This arrangement was also used in England for four-winged mills, but was otherwise rare. Eight-wing mills can also be operated with four wings, six-wing mills with three or two wings.

The historic American windmill, better known in Central Europe as the wind turbine or wind rose, had a large number of six, but mostly more, blades. There are models with twelve and twenty-four or more wings. The Americans definitely use the name "windmill" for their construction. The many blades give good turning power in weak winds and are automatically turned out of the wind by a partly foldable and partly stiff double wind vane together with the rotor in strong winds.

Sail gate wing

The sail gate wing consists of a lattice cross made of slats, which has to be covered with a canvas in order to span the area. These wings must be sailed individually at the beginning of the work, that is, each individual wing must be climbed and the sails must be tensioned on the wing with lines. The sails are made of sailcloth, similar to a ship's sails, provided with a protective coating and edged with a leech rope. At the leading edge of the sail, the sail is hooked into the rod with the luff rope in lugs and attached to the rear edge with lines that are thrown over the sheath ends protruding from the batten.

Depending on the wind strength, the sail area must be reduced or enlarged during working hours. The sails are reefed or left out, that is, parts of the sails are withdrawn or extended - a job that was pleasant in summer, but dangerous in winter with snow and icy lines. The fire of many mills as a result of overturning by hurricane-like winds and overheating of the brakes was often due to the wind area (sails, doors) being reduced too late or an insufficient brake to fix the wing cross.

Door leaf

A leaf type that is still widespread is the door leaf. The wing surface is built up here by large wooden boards (also called doors) that are hooked into the grilles of the wings.

With the wing types sail gate wing and door wing, the mill must be stopped in order to reduce the wing area when the wind increases. With four wings this had to be done four times, which led to a lot of effort.

Louvre flap wing

First with the Dutch windmills, later also with other types of mills, the louvre flap blades or, as they are also called, the louvre blades became widespread. Here the wing surface is formed by louvre flaps . They can be placed perpendicular to the wind and thus form a wing surface. When the work is finished, they are placed horizontally again so that the wind can blow through them unchecked. This type can be controlled via a central adjustment mechanism while the blades are rotating , i.e. during operation, so that the mill does not have to be braked to adjust the blinds.

This made it possible to react faster and also automatically to the different wind strengths by means of centrifugal force control and to not expose the "windmill" machine to the fluctuating speeds caused by gusty winds and thus to achieve a more even run. The adjustment mechanism of the blinds protruding from the wing head is called a spider head .

This development prevailed above all in the central areas of Germany, in the Netherlands there are largely sail gate wings. In central Germany, Paltrock windmills are designed with a wind rose and louvre blades.

At the beginning of the 20th century there were several aerodynamic improvements to the wings, as considerations from the aerodynamics of aircraft wings were carried over to windmill wings . However, these have only caught on in isolated cases and were only used more widely in the development of the new wind turbines.

Bilausche Ventikanten

This type of the most modern windmill blades go back to the German engineer Kurt Bilau . Between 1920 and 1924, together with Albert Betz, he developed this type of windmill wing, one of the last great innovations in windmill technology, from his experience in aircraft construction and called it Bilauschen Ventikanten (Latin venti = of the wind, the winds - in German = "wind edges"). This wing is constructed according to scientific methods with the help of aerodynamic optimization and has the aim of increasing the wind yield by reducing the flow-related energy losses and thus increasing the economic use of the windmill.

In the course of the mill's death, Bilau was honored as the “savior of the windmills”. The visionary Kurt Bilau also foresaw that the windmills of the day after tomorrow would only have three aerodynamically constructed blades - as is the case with modern wind turbines. The first mill that was equipped with the Ventikanten was the Ristedter mill in Syke . Their performance could be increased threefold.

The light metal wings, designed based on the model of aircraft wings, consist of two wing surfaces arranged in an approximately V-shape to one another (front stern, rear stern), between which there is a longitudinal gap. This gap between the two wing surfaces could be closed or opened depending on the wind strength during operation by an adjusting mechanism, that is, the rear stern could be pivoted about the longitudinal axis. When the gap was closed, the stern acted as a sail surface, unfolded as a brake. The mill thus had its own wind brake mechanism in addition to the axle brake. In this way, the wing cross could be stopped after two to three revolutions at full wind strength. With a compass rose as a wing tracking system and a centrifugal governor, the drive of such a mill could be controlled automatically. Even when the wind was weak, these wings turned and moved the millstones.

Disadvantages of the vent edges were their design-related weight (wing cross ~ 12 t with a wing diameter of 24 m) and their high price. Several mill builders used the Bilausche system until the middle of the 20th century, so that there were once more than 140 mills with this special drive system in Germany, of which only ten still exist (for example Donsbrügger Mühle ( Kleve -Donsbrüggen), Reeser Scholtenmühle, Breberer Mühle, Stommelner Mühle in the Rhineland; Neubukower Mühle in Mecklenburg-Western Pomerania and Turmholländer windmill Pahrenz in Hirschstein , OT Pahrenz, Saxony).

Sail pole wings

This simple wing system, which is widespread in the Mediterranean, consists of rods covered with sail. To do this, four, five or six rods the length of the full wing cross diameter are inserted one behind the other through the protruding end of the wooden wing axis and braced together with wire ropes and again centrally to the axis end. So an impeller is made up of eight, ten or twelve blades, which are covered with triangular sails. Windmills of this type are called sailing windmills . There have even been two windmills with fourteen (Greece) and one with sixteen (Greece) such blades.

Wing tracking

Windmills always have to be turned into the wind so that it can blow from the front onto the circular plane of the wheel for optimal energy utilization. So that this also happens with changing wind directions , this plane of the wing cross must be turned towards the wind direction. For this purpose, on the back of the mill box on post and coker windmills or on the hood on Dutch and tower windmills, the cod-end bar for pre-turning is attached. It usually consists of five, rarely three bars: the middle bar, the actual codend, and the two (or one) V-shaped bar pair (s) - the swords or scissors that go through two (one) Cap / mill box running cross beams (Spreet beams) are attached. Since the entire building of a post mill with all the machines and the blades was turned into the wind, a lot of weight was added. To support this, piles were driven into the ground around the post mill. These were connected to the cod-end by means of a pulley system (or chains and adjusting wheel (jogger or Kroy reel)) and so the mill was turned in the new wind direction.

With the Dutch windmills, only the hood had to be turned into the wind (ndl. Bovenkruier , top slewing ). Either the codend was turned into the wind without tools or a winch (adjusting wheel) or a reel, the so-called Krühhaspel (Niederdt. Kroyhaspel from Nland . Kruihaspel ), also called a jogger , was attached to the end of the codend . This is a crank that has a chain or two twisted on it. The loose ends of the chains were anchored to the gallery or to the floor. This chain was also attached to the piles that were embedded in the ground around the Mühlenberg, so that the wings were chipped into the wind with the Kroy reel (ndl. Kruit ). That is why in the Netherlands windmills with such an external harvester are called buitenkruiers (external harvester, external rotator).

Furthermore, there is little spread inland Dreher (NDL. Binnenkruiers ) with built-in hood Krühmechanismus. The hood can be turned from the inside with a crank (for example the Schermerhorn mills in Noord-Holland and many tower windmills, which appear squat because of the huge hood ). In England, in certain areas, preference was given to an internal brewing system with a covered chain wheel (gaff wheel) accessible from below via an endless chain at the end of the mostly boat-shaped cap with triangular gables (for example in Norfolk ).

In Northern Europe and Eastern Germany, a number of Dutch windmills have been retrofitted with a compass rose. The wind rose, a wind turbine up to more than 3 m in diameter and 6 to 12 blades, was invented in 1743 near Wigan , England, by Edmund Lee, a blacksmith (patented 1745), and was first used there for automatic canopy tracking . It was mounted above the rear part of the mill hood at right angles to the impeller in the wind, so that the mill was automatically turned into the wind via a gear. This compass rose was mainly used with the types Dutch and Paltrock windmills , in England, where they took on quite huge dimensions (over 3 m in diameter), also with post mills and very rarely with coker windmills. Most of these wind roses are single-wheeled, but individual mill builders also use double wind roses (two wind roses next to each other on a frame) - but these have hardly caught on. There are also windmills that have both a compass rose and a gaff wheel tracking system ( Janwlecke windmill from 1780 from Westrup (today Stemwede-Westrup, Minden-Lübbecke district) in the Hagen open-air museum ).

Wing language

Depending on their position in the braked state, the blades of the windmills are used to transmit signals . Four to nine wing positions are possible, some of which can only be recognized by differences in the sails or the position of the louvre flaps. For example, the break in operation can be seen from a distance and the customer does not make an effort to go to the mill. The miller also signals important family events of the miller's family (birth and death) using the joy or mourning scissors. The signals differ regionally, so that one cannot speak of a uniform signal language.

Cultural history

conservation

Many people see windmills as valuable evidence of technical development. This is likely to have been felt in earlier times, especially since attention was clearly paid to the aesthetic appearance when the mills were built. The maintenance of the mills right through to functional repair has been intensively promoted over the past decades.

Some friends of the windmills make use of the wind power and the work done by the windmills themselves. Small museums and mills set up in open-air museums also contribute to this. Almost every at least medium-sized open-air museum in northern Germany, the Netherlands, Flanders and Denmark has one or more windmills. The windmills in the Zaanse Schans museums north of Amsterdam and the International Wind and Watermill Museum in Gifhorn are a particular focus .

The mills of Campo de Criptana and the windmills of Consuegra are particularly famous in Spain . Nevertheless, there is still a need to maintain these old contemporary witnesses at various locations. Works affected by the worm sting and ruinous remains of many windmills are waiting in some places for the connoisseur and lover who will make them appear again in their old beauty. Since the maintenance of windmills is associated with considerable financial outlay, even some mills in museums are not in optimal condition. Another problem is new uses. If a windmill is used as an apartment or as a local history museum, such as in Esens , the mill is gutted and the mechanics are lost.

Naming

Like all outstanding buildings, windmills have a name. In Germany, the naming mainly follows the mill location, the builder or the previous or current owner (mostly miller) or their reference person as well as outstanding characteristics.

Mills named after their location lead the location as a place name adjective in front of the term windmill or as a place name after it: Breberer Windmühle or Windmühle Breberen . Another variant is the indication of the compass direction such as Westmöhl (Westmühle) or Südermühle .

Windmills, which are named after the builder or miller, have the surname as an adjective before the term windmill, for example Stechansche Mühle , rarely Mühle Stechan (today's Britzer Mühle was named after the second owner). Mills named after people are often given a local name after they have been closed, as the former miller's or owner family is no longer related to the mill. In some cases, mills were named after relatives of the miller or builder, for example after the wife, such as the 30 m high windmill Amanda in Kappeln, one of the highest windmills in Germany and Europe.

Among the properties, names like Bannmühle , Peldemühle (today the museum mill in Wittmund is called ) or Rote Mühle should be mentioned. In East Friesland and Schleswig-Holstein in particular, windmill names can also be found that indicate a successful job, such as in mines, for example Glück zu (Müllergruß), Fortuna or Hope . Dutch names such as De Goede Verwachting or De Vrouwe Johanna can also be found in the Emden area .

In the Netherlands the naming is mostly different. There, mills are given a name that rarely refers to a specific person, but mostly everyday terms such as animal and plant names, properties or objects such as De Hoop (hope), De Vrijheid (freedom), De Eendrag (concord), De Noord , De Palmboom (palm tree), De Walvisch (whale), De Steene Molen (stone mill), De Brandersketel (burner kettle), De Witte (the white one). As a result, several mills in the Netherlands have identical names.

Sometimes windmills are named after their location, such as the largest coker windmill, the Wingerdse Molen near Dordrecht, or the Wimmenumer Molen in Wimmenum near Egmond . The world's tallest windmill De Nolet (Brennerdynasty in Schiedam) or De Wilhelmina (after Queen Wilhelmina of Orange-Nassau) were named after its founder, owner or 'patron' .

The name and the year of manufacture are in the Netherlands on the decorative plate or jewelry board on the front of the cap below the wing cross. In Germany, the mills there rarely bear their name, if at all, but rather a motto like "Ech kier de Nuet on schaff öch Bruet, But Koar on Kear jieft Gott der Heär" (I turn the need (around) and create bread for you , But the Lord God gives grain and kernel) or “Mien Aerm send stark, Drom brengt mech Werk” (“My arms are strong, that's why I get work”) or the year of construction.

In England windmills are mainly named after their location ( e.g. Heckington , Alford , Sibsey , Waltham (Lincolnshire), Sutton (Norfolk), Heage (Derbyshire)), and also after the owner ( e.g. Dobson , Hewitt , LeTall (Lincolnshire) ) or according to relevant terms from the area around the mill such as field names and road names ( Carsington Pasture , Fordbridge Lane (Tower Mills in Derbyshire)).

In Denmark and Sweden, mills are mainly named after their location, such as Agersø Mølle , Agersø , Blåbæk Mølle , Blåbæk, or Gedesby Mølle , Gedesby, or after people like Christiansmølle , Gøhlmanns mølle (both Denmark) or Kulla Gunnarstorps Mölla in Helsingborg in Sweden.

In France, names are less often based on the location (such as the St. Poucy mill in St. Poucy, Auvergne ), but rather according to names, people, saints and characteristics that were or are related to the mill, such as the Mill Alphonse Daudet (French: Moulin d'Alphonse Daudet) in Fontvieille , Provence , named after the writer of the same name who lived there for a while. The mill used to be called Ribet or Saint-Pierre .

A Spanish tower windmill in La Mancha near Consuegra has a very fitting name : Alcancía ( money box ).

Windmills in Literature

Cervantes ' famous literary figure Don Quixote thinks windmills are giants with many arms and puts them in a duel. Sancho Panza comments on Quixote's failure as follows: ... didn't I tell Your Grace that you would like to consider what you are doing, that it is only windmills, and that can only be misunderstood by those who have windmills in their heads? That is why the saying “fight against windmills” today denotes a hopeless campaign against an unchangeable state.

The picture story of the farmer and the windmill (in the post mill) by Wilhelm Busch is also known .

In George Orwell's Animal Farm , the windmill and the generation of electrical energy also play a role as a contested symbol of progress.

Reinhard P. Gruber's essay Everything about windmills provides a literary overview of windmills .

Gustave Doré : Don Quixote rides against windmills (1863)

See also

literature

Newer literature

- Leo Hopf: Mill technical internship.

- Volume 1: Milling . Leipzig 1950.

- Volume 2: Mill construction . Leipzig 1952.

- Jannis C. Notebaart: Windmills. A technical consideration of four-wing classics in Germany and the Netherlands . Mouton, The Hague / Paris 1972, DNB 730119157.

- Johannes Mager : Mill wing and water wheel . 2nd edition, Fachbuchverlag, Leipzig 1990, ISBN 3-343-00257-7 .

- Matthias Heymann : The history of wind energy use 1890-1990 . Frankfurt / New York 1995, ISBN 3-593-35278-8 .

- Rüdiger Hagen: Historical mills and their technology: artistic and technical drawings , Reprint-Verlag, Leipzig 2004, ISBN 978-3-8262-0822-5

- Torsten Rüdinger, Philipp Oppermann: Small mill knowledge - German technical history from the friction stone to the industrial mill . 2nd, revised edition, terra press, Berlin 2012, ISBN 978-3-9811626-7-7 .

- Werner Schnelle (author), Rüdiger Hagen (editing): Mill construction. Preserve and preserve water wheels and windmills . Ed .: German Institute for Standardization . 2nd, revised edition, Beuth Verlag, Berlin / Vienna / Zurich 2012, ISBN 978-3-410-21342-0 .

Historical literature

- Johann Peter Eberhard : Mathesi applicata . 1757 digitized .

- Christoph Bernoulli : Practical manual for mechanics, machine and mill builders, and technicians in general . 1836 digitized .

- Adolph Lohmann: The water grinding mill construction . 1856 volume 1 .

- Friedrich Kettenbach: The miller and mill builder. Practical manual for millers . 2 volumes, mill builders and technical schools, Leipzig 1907/1908.

- Vertical axis wind turbine . In: Franz Maria Feldhaus (Ed.): The technology of prehistoric times, historical times and primitive peoples. A handbook for archaeologists and historians, museums and collectors, art dealers and antiquarians . Wilhelm Engelmann, Leipzig / Berlin 1914, Sp. 1321–1331 ( digitized [PDF; 3.5 MB]).

- Rudolf Sacher: manual of the miller and mill builder . 2nd edition, Leipzig 1924.

- Albert Betz : Wind energy and its use by windmills . Ökobuch, Grebenstein 1982, ISBN 3-922964-11-7 (first edition: Vandenhoeck & Ruprecht, Göttingen 1926).

Web links

- German Society for Milling Science and Mill Maintenance (DGM) eV

- Photo documentation of old mill locations

- TIMS The International Molinological Society, International Mill Association (English)

- International Wind and Watermill Museum Gifhorn

- Time for something to turn . In: Spiegel Online - Schulspiegel , about mill experts

Individual evidence

- ^ Vaclav Smil , Energy in World History . Westview Press 1994, p. 108.

- ^ Matthias Heymann : The history of the use of wind energy 1890-1990. Frankfurt am Main / New York 1995, p. 19f.

- ^ Piotr Michalak, Jacek Zimny: Wind energy development in the world, Europe and Poland from 1995 to 2009; current status and future perspectives . Renewable and Sustainable Energy Reviews 15, (2011), 2330-2341, p. 2330, doi: 10.1016 / j.rser.2011.02.008 .

- ↑ Erich Hau: Wind power plants: Basics, technology, use, economy . Berlin / Heidelberg 2014, p. 1f.

-

^ AG Drachmann: Heron's Windmill , Centaurus, 7 (1961), pp. 145–151

Dietrich Lohrmann: From the eastern to the western windmill , Archive for Kulturgeschichte, Vol. 77, No. 1 (1995), pp. 1–30 ( 10f.) - ↑ Paolo Malanima : European Economic History 10-19. Century. Vienna / Cologne / Weimar 2010, p. 96.

- ↑ Ahmad al-Hassan, Donald Hill: Islamic Technology. An illustrated history , 1986, Cambridge University Press, ISBN 0-521-42239-6 , pp. 54f

- ↑ Erich Hau: Wind power plants: Basics, technology, use, economy . Berlin / Heidelberg 2014, p. 2.

- ↑ Dietrich Lohrmann : From the east to the west windmill , Archive for Cultural History, Vol. 77, No. 1 (1995), pp. 1–30 (18ff.)

- ↑ a b Erich Hau: Wind power plants: Basics, technology, use, economy . Berlin / Heidelberg 2014, p. 3.

- ↑ Robert Gasch, Jochen Twele (Ed.): Wind power plants. Basics, design, planning and operation . Springer, Wiesbaden 2013, p. 20.

- ↑ Figure .

- ↑ Axel Stefek: Wind. Propulsion from the air. In the S. (Ed.): Energy in Weimar from the Middle Ages to modern times. Weimar 2016, pp. 139–161, here pp. 151–152.

- ↑ http://www.lueben-damals.de/kreis/windmuehlen.html

- ^ Museum Bad Rappenau , December 3, 2017

- ^ Vaclav Smil , Energy in World History . Westview Press 1994, p. 109.

- ↑ Alois Schaffarczyk (Ed.): Introduction to Windenergietechnik , Munich 2012, p. 26f.

- ↑ Example photo : Thorpeness post mill in Suffolk

- ^ Belgian mill database .

- ↑ Wendhausen windmill

- ^ Description of the Hetzemühle on city map Zittau, Görlitz and Weißwasser

- ^ Liebemühle in Obercunnersdorf on Europeana

- ↑ Windmill Malliß on zwillingswindmuehlen.de

- ↑ Schönbach on faust-schoenbach.de

- ↑ During a visit to the Schleswig-Holstein open-air museum in spring 2007, the post mill had to be supported with a scaffold and the cap windmill was missing a wing

- ↑ The windmill of the songwriter Hannes Wader became known among other things

- ↑ Miguel de Cervantes Saavedra - The ingenious Junker Don Quixote of the Mancha . Translated from the Spanish by Ludwig Braunfels. Artemis and Winkler 8th edition 1997 p. 68 ISBN 3-538-06531-4

- ↑ The facsimile pages of this story can be found in Busch Complete Edition in four volumes, Volume 1, from images 115 to 123.

- ↑ Everything about windmills , aq-Verlag.de (1984), ISBN 978-3-922441-08-3 .