contraption

Devices used in mechanical engineering to workpieces to be positioned to keep their position, they tighten and sometimes to guide tools. Together with machine tools , tools, measuring and testing equipment, they are therefore part of production equipment (according to DIN 6300), work equipment (according to ergonomics ) and operating equipment (according to business administration ).

They can be divided into universal and workpiece-dependent devices. A vice, for example, is a simple, workpiece-independent device for determining the position. Special, workpiece-dependent devices, devices and apparatus are manufactured in workshops and companies involved in tool and special machine construction.

purpose

Manufacturing fixtures is usually worthwhile for series production or small series, but it can also be worthwhile for a single workpiece. However, a device can also be an indispensable aid to carry out work whose quality cannot otherwise be guaranteed. Clamping devices for the unambiguous determination of the position of a workpiece or several workpieces are often only manufactured for this purpose. If, for example, the frame changes in the production of bicycles, the device is exchanged or converted for the changed production.

example

A simple example of a device is a drilling template that, with a lower plate or cassette and an upper plate with predefined bore sleeves, allows workpieces to be drilled quickly without having to measure and mark the individual workpiece again and again : the workpiece is placed in the a suitable template and drills off all specified drilling positions.

Functions

A distinction is made between the following functions for the construction of a device:

- Positioning to determine the position in a statically determined position ( degree of freedom equal to 0)

- Determine to fix the position with a light force

- Clamping to fix the position against the process forces occurring in production

- Lead if necessary : impose a compulsory movement

- if necessary parts : allocating a plurality of workpiece layers for processing

These functions have to be defined, reproducible and carried out with the accuracy required for production.

species

There are mechanical , magnetic , hydraulic or pneumatic devices. But there are also devices that can use several of these methods simultaneously if necessary.

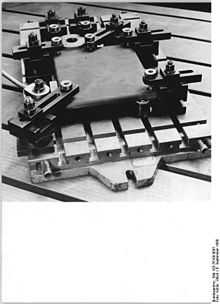

In addition to so-called workpiece-related devices, there are also device systems (groove or hole systems) that can be used to create variable clamping devices. The workpieces are held with clamps, for example .

In the field of electrical engineering, a device is an aid in the form of a specific circuit arrangement of individual components or a device , such as a charger that is used to charge a battery. A solder bath for soldering assembled printed circuit boards is also known as a soldering device.

See also

literature

- Achim Trummer; Helfried Wiebach: Devices in production technology: development, assembly, automation. Vieweg, Braunschweig 1994, ISBN 3-528-04938-3

- Bozina Perovic: Devices in machine tool construction - Basics, calculation and construction , Springer, 2013.

Web links

Individual evidence

- ↑ Perovic: Devices in machine tool construction p. 1.