Archimedean screw

An Archimedean screw is a conveyor system that consists of a helix and a trough. The term screw pump or screw conveyor is more appropriate . The invention of such a water lifting system goes back to antiquity and is usually attributed to the Greek technician Archimedes . Its main historical application is the transport of water to a higher level for irrigation and drainage purposes . Today it is mostly used to convey bulk goods .

term

In ancient times, the screw pumps were called cochlias in Greek and cochleas in Latin because of their resemblance to a spiral sea shell . The name screw pump is misleading because it is neither a screw nor a pump. According to DIN 1184, it is a constant pressure lift. The term screw pump (in English it is also called screw pump) would be more appropriate and the manufacturer MAN also named it that, but the term was already used elsewhere in German. This is why the term screw pump has established itself among experts in the industry. This term was derived from the Dutch Vijzelpomp, because the Dutch were the largest users of screw pumps over the past 500 years and Dutch manufacturers dominated the German market until a few years ago.

principle

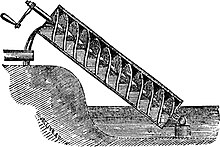

The screw is located in a tightly fitted trough or pipe made of steel or concrete and rotates around its central axis. Chambers are formed by the screw and the trough, in which the water is screwed upwards. These chambers are delimited at the top and bottom by a respective leaf section of the spiral. Due to the rotation of the screw, all chambers move in the direction of the screw end. At the end of the screw, the water runs out of the disintegrating chamber, at the beginning of the screw a new chamber is created which fills with water from the inlet.

The wall thickness and diameter of the central tube, with their moment of resistance, determine the deflection and thus the achievable delivery heights. For a long time, no screw pumps with lengths that were longer than 10 m were used, as they broke after a short time. Only when it was noticed that they were bending upwards due to the displacement of the water during operation, longer screw pumps could be operated by adjusting the corresponding parameters. The first machine with an overall length of 18 m was shown at the Brussels Expo 58 in a show pumping station in the Dutch pavilion and was a sensation for experts.

The Archimedes' screw is a special case of the screw conveyor, as gravity is used to transport the conveyed medium forward. For this reason, the Archimedes' screw can only convey horizontally or diagonally upwards, whereas screw conveyors are also able to convey goods vertically. Screw pumps mostly convey liquid media, screw conveyors mostly solids or highly viscous media.

At higher delivery heights, the screw pumps are arranged as cascades (already on a Roman representation).

history

Ancient and Middle Ages

The use of Archimedean screws can be documented for the first time in antiquity. The invention is usually attributed to the Greek mathematician and technician Archimedes , who lived in the 3rd century BC, but there are also hypotheses in technical-historical research that such devices were previously used in Mesopotamia. Stephanie Dalley interprets a cuneiform message from the Assyrian King Sennacherib from the 8th or 7th century BC as building instructions for a device with a similar function. These were driven by windmills , by muscle power or, on rivers, by water wheels and, among other things, were made by wrapping a wooden core in several layers in a spiral with flexible rods and sealing them with pitch .

Vitruvius has given precise details on the construction of a screw pump . In his work “Ten books on architecture” (“De architectura libri decem”), which was published between 33 and 22 BC. In Volume X Mechanical Engineering ("Machinarum", there Chapter 6), he puts together specifications according to which the axis is to be made from a round wooden pole, the diameter of which should be one sixteenth of the length. The circumference is divided into eight equal sections, the length as well, so that a square division is created. The blades of the screw pump are created diagonally across the crossing points of these squares from flat strips of willow cane or willow wood and sealed with pitch. The drive is done by human power ("hominibus calcantibus"), but is not explained in more detail. Ancient depictions on wall paintings and terracotta show the drive by a person who drives the drum by kicking it. Rough recalculations of the pump output with a continuous output of around 100 watts and an overall efficiency of 40% come to a delivery rate of around 10,000 liters per hour. Such screw pumps for the Roman silver mining in Spain have been handed down to us in the second century AD.

Italian Renaissance and Dutch Polder Drainage

At the beginning of the 15th century, the first evidence of the use of screw pumps can be found in Renaissance Italy, namely in Padua and in the arsenal of Venice. It is possible that this technology was already being used in the Netherlands at that time for drainage for land reclamation. Water snails for this purpose were used there in large numbers around 1600 by technicians such as Jan Adriaanszoon Leeghwater . The Dutch used these screws to drain entire stretches of land. The so-called "polder mills" were operated with wind power. In this way, the windmill became the symbol of the Netherlands. " Flutter " (mills) (in Holland "tjasker (molen)") were inexpensive and simple systems that could be turned manually into the wind. Around 1880 there were still 130 such drainage mills in East Frisia ; is preserved until today z. B. the water mill Wedelfeld in Sande .

Essential dimensions

The figure opposite shows the most important dimensions of a common Archimedean screw:

- : Core tube diameter

- : Screw diameter

- : Installation angle

- : constructive head

- : Water level difference

- : maximum head

- : required hydraulic head

- : Number of gears (here: 4)

- : bladed length

- : Pitch

Application and similar mechanisms

Because of their reliability and low maintenance, the screws are mainly used in sewage pumping stations, in sewage treatment plants in the inlet or for the return sludge. The simple and robust design of the screws has clear operational advantages over centrifugal pumps. It is precisely the properties of the extremely low clogging tendency and the insensitivity to coarse materials that are becoming increasingly important due to the massive increase in the entry of wet wipes and fleeces into the waste water flow. Another, little-known advantage here is the gentle handling of the pumped medium compared to centrifugal pumps, which makes wastewater treatment much easier. In combine harvesters , the grain is conveyed to the truck driving alongside by an Archimedean screw. In laser printers and copiers , toner is transported by Archimedes' screws.

The reverse of the working principle is the hydropower screw . Here the screw is driven by the weight of the water.

The eccentric screw pump , which looks similar to the Archimedean screw and is actually a positive displacement pump , works according to a different principle .

The Englishman Francis Pettit Smith and the Swede John Ericsson used a similar screw shape independently in the 19th century as a propulsion system for ships. The marine propulsion of the General-Admiral tank frigate, which was put into service in 1875 , had a construction similar to the Archimedean screw. The propeller later developed from this .

A simple construction consists of a hose wound in a spiral shape on an inclined shaft, the lower opening of which dips into the flowing water again and again with each rotation, the shaft is driven by a small water wheel without the need to build a large bucket wheel , which is expensive and costly . This construction principle is also used for ball tracks ( children's toys or kinetic art ).

Probably the simplest construction for pumping up water with the help of a spiral from flowing water consists of a water hose, which is fixed in a spiral on a water wheel in a vertical plane. Here, too, the hose opening (on the outside of the spiral) plunges into the flowing water again with every turn; the rotation of the wheel causes the water to flow to the inside of the spiral, overcoming altitude. The other end of the hose is coupled to the pipe, which at the same time forms the shaft of the scoop wheel and directs the scooped water to the field. Such spiral water wheels are used in Vietnam , for example , with curved hollowed out bamboo tubes being used.

In such a pumping station, the diameter of the pipes should be selected as large as possible. The volume flow is dependent on the fourth power of the radius (due to the Hagen-Poiseuille law ). For example, reducing the pipe diameter by half would increase the flow resistance 16 times or increasing the pipe diameter by three times (one and a half inches instead of half an inch) the volume flow by 81 times. By increasing the pipe diameter, there is not so much work to be done. With motor-driven pumps, larger pipe diameters enable greater pumping heights or more flow with the same energy input or power or energy savings.

The amphibious vehicles of the ZIL-2906 series work with Archimedean screws instead of wheels or chains.

literature

- Peter J. Kantert: practical manual screw pump . Hirthammer, 2008, ISBN 978-3-88721-202-5 ( table of contents ; also in English, ISBN 978-3-88721-896-6 ).

- Peter J. Kantert: Praxishandbuch worm pump - 2nd edition, 2020, DWA, ISBN 978-3-88721-888-1 .

- Great Britain and Napoleon. Two new steamships with Archimedean propellers . In: Illustrirte Zeitung . No. 21 . J. J. Weber, Leipzig November 18, 1843, p. 332-335 ( books.google.de ).

- Gerhard Nagel: Ritz, manual of the water screw conveyor. 1968.

- Gerhard Nagel, Karl A. Radlik: Water screw conveyors , planning, construction and operation of water lifting systems. 1988.

Web links

Individual evidence

- ↑ On this in detail Stephanie Dalley, John Peter Oleson: Sennacherib, Archimedes, and the Water Screw: The Context of Invention in the Ancient World. In: Technology and Culture. Vol. 44, 2003, No. 1, pp. 1-26, doi: 10.1353 / tech.2003.0011 .

- ↑ John Gray Landels: Technology in the ancient world. Beck, Munich 1979, ISBN 3-8289-0362-2 , Chapter 3: Water pumps (Title of the original English edition: Engineering in the Ancient World. Chatto & Windus, London 1978).

- ↑ Friedrich Klemm : History of Technology. 3. Edition. Teubner, Stuttgart, Leipzig 1998, p. 38 f. ; Helmuth Schneider : History of ancient technology. Beck, Munich 2007, pp. 45-47 .

- ↑ Marcus Popplow: Technology in the Middle Ages. Beck, Munich 2010, p. 76 .

- ^ Dietrich Lohrmann : The Archimedean screw in the history of human work up to the 15th century. In: Verena Epp (Ed.): Work in the Middle Ages. Ideas and realities. Akademie, Berlin 2006, pp. 171–186, here p. 182 .