History of wind energy use

The wind energy is one of the oldest used by man forms of energy . A long time ago, mechanical work such as grinding grain and pumping water was carried out with the help of windmills (see wind pump ). This article describes the history of wind energy use on land and in the sea. Applications such as sailing boats , sailing wagons or gliding are not covered .

Windmills

Pre-industrial times

The oldest windmills are known from Persia (for grinding grain), Tibet (as prayer wheels ) and China (for pumping water). These had a vertical rotor axis and a horizontal turning circle plane. The Persian windmill functioned as a resistance runner . The Chinese windmill , in which vertically standing junk sails automatically align themselves to the wind in a turning circle around their axis thanks to their specific rig , is a boom .

Windmills have been known in Europe since the 12th century. Right from the start, they were built as lift rotors with a horizontally lying rotor axis, which is still the basic principle of modern wind turbines today. This technology could arise from the coincidence of some historical circumstances:

- In the high Middle Ages the craft within the guilds had perfected.

- Growing general prosperity reduced the supply of cheap labor.

- The Christianization of the seafaring Nordic peoples (e.g. Vikings ) increased the exchange between them and Central Europe.

Water-powered bucket wheels for irrigation ("Noria") date back to the 5th century BC. Known from Mesopotamia . The first water-powered grinding mills are from the 3rd century BC. Attested from China . The ancient Egyptians , Persians and later the Greeks and Romans also used water mills. The condition for the use of hydropower is that there is a body of water with a sufficient gradient that carries enough water even in dry periods. Since this condition is not met in many places in the lowlands, but there (often) the wind blows stronger and more evenly, the windmill has established itself as the predominant type of mill in the coastal, flat regions, and the water mill in the more mountainous regions . The flexible, time and location-independent availability of drive power in any amount was the main argument for the use of mills that were operated with muscle power, such as von Göpeln .

In addition, there was the connection of the aerodynamic knowledge of the Nordic peoples with the craftsmanship of the Central Europeans, which enabled the development of windmill technology.

In addition to pure windmills, there are also mills that draw their driving power from water and wind at the same time. One of the few mills of this type still completely preserved today is the Hüvener Mühle in northern Emsland .

The windmills were improved over time and apart from grinding they were also used for threshing , pumping or scooping water, and for sawing, hammering or knocking. Even before industrialization, some wind-favored regions such as B. Denmark, the Netherlands and Northern Germany landscapes that have been strongly influenced by the commercial use of wind energy.

industrialization

During the onset of industrialization, the windmills were further improved in the 19th century. Before that, the abolition of the compulsory meal in Prussia in 1810 had already led to a significant increase in the number of mills. It is true that the steam engine and later the internal combustion and electric motors faced strong competitors, which ultimately largely displaced the use of wind energy in the 20th century. In the 19th century, however, there was initially a parallel growth. This was not least due to the initially higher cost of the steam engine, which was only gradually compensated for by advances in transport (cheaper coal transports by using the railroad ).

The climax of windmills as mechanical sources of power is dated by historians in Germany in the 1880s, and thus in the high industrialization . In niches, for example in rural regions with poor traffic connections, these decentralized energy sources persisted even into the 1950s. In 1895, shortly before the start of electrification, a nationwide census showed that of the 150,000 companies that used mechanical power sources, 18,000 were still using wind power, while 54,000 had water wheels or turbines and 59,000 had a steam engine. However, the average power of the steam engines was significantly higher than that of the windmills. After that, usage decreased. In 1914, at the beginning of the First World War , the number of windmills is estimated at around 11,400, in 1933 4,000 to 5,000 windmills were still in operation. The last improvements to windmill technology were made in Germany in the 1940s by Kurt Bilau (Bilausche Ventikanten), in Holland a. a. by Ten Have and van Riet.

The 19th century brought further advances and possible applications with the beginning of electrification, which also had an impact on windmills. For example, during Nansen's Fram Expedition (1893–1896), a wind-powered generator was used to generate electricity for the electrical lighting on board during the long drift on the pack ice towards the Pole and past it to Spitsbergen.

In North America , the Westernmill was developed , which was and is mainly used for pumping water. It was the first that could turn itself out of the wind in a storm. With conventional mills, however, the miller always had to make sure to secure the mill from an approaching storm in order to protect it from damage. With this, and with the industrial production of the mills, the way was clear for mass use. Some of these mills are still in use in rural areas around the world, mostly to drive water pumps, but also to generate electricity at locations that - such as remote farms - are far from the grid. Even today new Westernmills are still being built, mostly built and set up by local craftsmen or hobbyists and enthusiasts from nostalgic motifs.

Wind turbines

Wind power plants developed from windmill technology. With the commercial use of electrical energy in 1882, electricity gradually began to become an important technical aid for the population as well. Initially, only decentralized networks were set up, which were often operated with direct current . Today's network , on the other hand, was not created until large-scale electrification took place in the 1920s. In order to improve the supply of electrical energy , attempts were therefore made in the late 19th century to generate electrical energy with the help of wind energy. Since the windmills were still very widespread at that time, there were several thoughts to convert them to operate a dynamo .

Charles Francis Brush built a wind turbine on the basis of the Westernmills in 1887/88 , which he used to supply his house with electrical energy from a battery storage system.

The Dane Poul La Cour then - the displacement of windmill technology by electrification had already started - scientifically researched the fundamentals of technology. He was one of the first scientists to apply his findings to the conversion into electrical energy and in 1891, with funds from his government, set up a first test facility in Askov on Jutland . Important developments for today's wind turbine technology are due to his good scientific foundation, his systematic approach and his skill in the practical implementation of his designs. He ran for the first time the wind tunnel trying - including the aerodynamics of the wing shape - and came to the concept of high-speed , a plant that wingtips moving in faster than the wind. One of the systems he designed was marketed as a commercial product by Lykkegaard, and by 1908 72 units had already been installed in Denmark to supply rural settlements.

The construction of wind power plants got a boost from the rise in fuel prices and shortages in the First World War . After the war, fuel became cheaper. Wind turbine technology remained a niche in technical development for a long time.

In 1920, Albert Betz , physicist and then head of the Aerodynamic Research Institute in Göttingen (renamed DLR in 1997), with strictly scientific research on the physics and aerodynamics of the wind rotor, laid further foundations for the development of wind turbines. He formulated Betz's law for the first time and showed that the physical maximum utilization of the kinetic energy of the wind is 59.3%. His theory of the shape of the wings is still the basis for the design of the systems today.

The Savonius rotor , a flow-through turbine with a vertical axis of rotation with a high speed of about 1.6, can be described as a lift and drag rotor , was invented around 1925 by the ship's officer Sigurd Savonius . The flow dynamics of this turbine are very complicated, there is no valid physical-mathematical model for it yet.

The French Georges Darrieus patented the Darrieus rotor in the USA in 1931 , also a design with a vertical axis, but a fast runner. Darrieus apparently never built a model of the rotor named after him himself; After filing the patent, he only built machines with a horizontal axis - probably because he saw that the horizontal axis was clearly superior.

In Germany at that time there were ideas and attempts from Wilhelm Teubert , Ferdinand Porsche , Hermann Honnef , Franz Kleinhenz (MAN) and Ventimotor GmbH in Weimar. Hermann Honnef pursued the boldest ideas of large wind power plants and served them to the rulers in the Third Reich under various aspects. However, his proposed double-rotor technology was a technical mistake. Among other things, he succeeded in setting up a test field with systems up to 17 kW - near Berlin, in Bötzow on Mathiasberg .

By the Thuringian Gauleiter Fritz Sauckel and the member of the Freundeskreis der Wirtschaft Walter Schieber based company Ventimotor GmbH in Weimar promoted under the slogan "wind power for wehrbauer " decentralized wind turbines as a suitable power supply as part of the General Plan East after a possible final victory . In 1943, Ventimotor's activities were largely discontinued in favor of aircraft construction. The head of the construction department of Ventimotor and head of the aerodynamics department of the Weimar engineering school Ulrich W. Hütter later became known as the German "wind energy pope".

Another milestone was the 1.25 MW Smith-Putnam plant (two wings, leeward runner ), named after Palmer Cosslett Putnam in Vermont , USA, in 1941. The plant ran intermittently until 1945, then one of the wings broke. The materials or material qualities required for this size were not yet available at the time.

In 1951 the German-Austrian wind power pioneer Ulrich W. Hütter designed a 10 kW system with a rotor diameter of 11 m, which was mass-produced by Allgaier Werke . Around 200 pieces were exported mainly to South Africa, Argentina and India. A system still adorns the headquarters of the Klöckner company in Bonn and is fully operational.

On the Swabian Alb near Geislingen an der Steige , he built the original model of all modern wind turbines in 1957, the 100 kW StGW-34 system with a 34 m rotor diameter. It received new rotor blades made of GRP in 1969 . Fiber composite components with a length of 17 m were unusual for this time.

In 1957, Johannes Juul built the Gedser wind turbine in Denmark , which became the “archetype of the 'Danish wind turbine'” and, thanks to its innovative design, was a major breakthrough in the history of wind turbines. It had three wings, which were braced together for reasons of stability, and a directly grid-connected asynchronous generator with a nominal output of 200 kW. The power limitation was carried passively by stall (stall regulation), limited at power failure controlled by centrifugal force, the blade tips of rotor speed. The plant ran very reliably until 1966, when it was shut down for cost reasons. However, it was not dismantled and experienced a renaissance in 1977 when it was put back into operation under an agreement between a Danish institution and NASA and served as a test facility for several years.

In March 1978, the wind power plant of the Danish Tvind School went into operation with three rotor blades made of GRP on the windward side of the tower and an output of 1 MW, which was still in operation 34 years later with interruptions. In the early 1980s, during a surge in demand from the USA, the Danish concept for wind turbines prevailed. Typical were the asynchronous generator ( squirrel cage rotor ), one or two fixed speeds and three rigid rotor blades ( stall control ). This type of construction remained predominant until the early 1990s and systems below around 500 kW.

German test facilities from 1978

1978 approved by the Federal Ministry of Research, was 1983 to 1987 in Kaiser-Wilhelm-Koog with Marne the test facility Growian ( Gro SSE Wi ndenergie- on location). With a rotor diameter of 100.4 meters and a rated output of 3 MW, it was the largest system built in the world at the time, but larger than was controllable at the time and did not even achieve permanent test operation. After the failure, a smaller model WKA-60 (Growian-2), only about half the size, with a three-blade rotor instead of a two-blade rotor was developed without, however, abandoning the unsuitable concept of the leeward runner. A system of this type was operated on Heligoland from 1990 onwards , problems arose again (especially from lightning), and since the damage could no longer be insured after the third failure, there were only four systems in total.

On the wind turbine test field Stötten on the Swabian Alb was u. a. from 1959 to 1968 Ulrich Hütter's W34 wind turbine with a rotor diameter of 34 m and a nominal output of 100 kW. From 1982 to 1985 the WEC-520 built by Voith stood here with a generator in the base of the tower, a rotor diameter of 52 m and a nominal output of 270 kW.

In contrast, Germany's first wind farm with 30 small plants based on the Danish model, the West Coast wind farm, was built on the former Growian test site in 1987 . At the beginning of 1991, what was then Europe's largest wind farm was connected to the power grid and delivered around 19 million kWh of electricity per year. Windenergiepark Westüste GmbH today offers interested visitors an information center on the history of wind energy.

The commercial wind turbines, which at the end of the 1990s also delivered the yield of 12 GWh per year aimed at with Growian, were variable-speed with a grid converter and had blade angle adjustment - two innovations introduced with Growian - but, like the Danish-type systems, had running in front of the tower Three-blade rotors.

Beginning of the expansion of wind energy

In the 1970s, as in Germany with the GROWIAN, funds for dubious development projects had been given in the USA. There was also broad support for wind energy there, however, which was based on the investment amount, so that there was no incentive towards high-yield large-scale plants. When it came to expensive repairs, the decision was often made to shut down the affected system. In Germany, the broad subsidy came later, in 1991, but with the Electricity Feed Act , which was geared towards earnings, in which the electricity network operators were obliged to purchase the electricity generated at defined prices. Because differences in yield were now more noticeable, not only more, but also better systems were built. Investors made sure that the manufacturer's promises about performance depending on wind speed and low downtime were contractually stipulated. As a result, the German economy also achieved a leading position in the world in this field of mechanical engineering .

The rapid expansion was reinforced in 2001 by the Renewable Energy Sources Act (EEG), so that by the end of 2003 around two thirds of European wind power plants were installed in Germany.

Today's technology

As the size of the system increased, the technology was also further developed. The maximum output of large systems in the megawatt range is achieved by rotating (torsion) the rotor blades ( pitching ), which results in a variable speed; the grid is fed into the grid via converters, with full or partial converters being used depending on the system concept used. These systems no longer load the grid with reactive power , but can be used for reactive power compensation .

Because the speed is independent of the mains frequency, these systems can be operated at the aerodynamically optimal speed for any wind speed. Thanks to the pitch mechanics (torsion of the wings with servomotors), the noisy stall effect above the nominal power no longer occurs.

Current developments aim to overcome the storage problem for renewable energies . Here, pumped storage (PSW), the 80% of the wind or photovoltaic electricity back to the grid again, the cheapest and cleanest method (no heat and exhaust gases) caching. In addition, water electrolysis using wind or photovoltaic electricity with subsequent methanation of the CO 2 from biogas plants is under development at Fraunhofer IWES and allows (as of April 2013) the wind and solar gas (methane) obtained in this way, however, with far less efficiency, for example in the gas network to store, from where it is then converted back into electricity in gas power plants if required.

Offshore

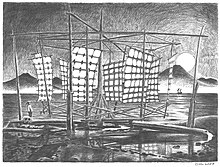

The use of wind energy at sea is ascribed great potential. There the wind is more constant and stronger than on the mainland. Similar to the extraction of oil and natural gas at sea, these systems are called offshore systems.

In December 2002, Horns Rev 1, the largest offshore wind farm in the world at the time, went online in Denmark : There are 80 wind turbines in ten rows with eight wind turbines each in the North Sea on 20 square kilometers. They generate 600 GWh of energy annually, enough for 150,000 Danish households.

In the German Exclusive Economic Zone (EEZ), the research platform “FINO 1” has been located in the North Sea since the end of 2003 . a. the conditions for offshore wind turbines are investigated. The “FINO 2” platform was set up in the Baltic Sea for this purpose. The third research platform “FINO 3” has been in the North Sea since 2009.

On October 20, 2004, a 108-meter-high E-112 test facility with an output of 4.5 megawatts in the Ems, in the immediate vicinity of the bank, fed electricity into the public grid for the first time. At that time, this type of turbine had the largest rotor diameter and the most powerful generator.

In the summer of 2008, construction of the first German offshore wind farm " alpha ventus " with a total installed output of 60 megawatts began on the FINO 1 research platform . The systems were commissioned from August 2009, the official commissioning on April 27, 2010.

literature

- Werner Bennert & Ulf J. Werner: Wind energy. VEB Verlag Technik, Berlin 1989, ISBN 3-341-00627-3 .

- Albert Betz : Wind energy and its use by windmills. Ökobuch, Staufen, unaltered reprint from 1926, ISBN 3-922964-11-7 .

- Robert Gasch , Jochen Twele (Hrsg.): Wind power plants. Basics, design, planning and operation. 9th updated edition Springer, Wiesbaden 2016, ISBN 978-3-658-12360-4 .

- Erich Hau: Wind turbines - basics, technology, use, economy. 5th edition. Springer, Berlin / Heidelberg 2014, ISBN 978-3-642-28876-0 . limited preview in Google Book search

- Matthias Heymann : History of the use of wind energy: 1890–1990. Campus-Verlag, Frankfurt 1995 (also Diss. German Museum Munich).

- Heiner Dörner : Three Worlds - One Life, Prof. Dr. Ulrich Hütter, university professor - designer - artist. extended Edition. Heilbronn 2002, ISBN 3-00-000067-4 .

- Theodore von Kármán : Aerodynamics, Selected Topics in the Light of Historical Development. Interavia-Verlag, Geneva 1956.

- Felix von König: Wind energy in practical use. Wheels, rotors, mills, wind power plants Udo Pfriemer Verlag, Munich 1981.

- Martin Kühn, Tobias Klaus: Wind energy - tailwind for a future-oriented technology , in: Renewable energy - Concepts for the energy transition, 3rd edition - Wiley, December 2011, ISBN 978-3-527-41108-5 .

- Paul La Cour : Wind power and its application to drive electricity plants . Translated by Johannes Kaufmann. Published by M. Heinsius Nachf., Leipzig 1905.

- Mario Neukirch, The international pioneering phase of wind energy use , Diss. Göttingen 2010, online (PDF).

- Jan Oelker: Wind faces. The start of wind energy in Germany . Sonnenbuchverlag, Dresden 2005, ISBN 3-9809956-2-3 , sonnenbuch.de .

- Manfred Kriener : History of Wind Energy. The power from the air . In: Die Zeit , No. 6/2012; detailed article.

Web links

- Heiner Dörner: Milestones in the use of wind energy . University of Stuttgart, 1997.

- Darrell M. Dodge: Illustrated History of Wind Energy Use .

- Achmed AW Khammas: Book of the synergy history and present of wind energy.

- Erik Grove-Nielsen: Winds of Change . Danish wind energy development 1975–2000 (English).

Individual evidence

- ↑ Hong-Sen Yan, Marco Caccarelli (Ed.): International Symposium on History of Machines and Mechanisms: Proceedings of HMM 2008 , Springer, 2011, ISBN 978-90-481-8138-4 , pp. 295-324.

- ↑ Michael Mende: Early industrial drive technology - wind and water power . In: Ullrich Wengenroth (Hrsg.): Technology and economy . VDI-Verlag, Düsseldorf 1993, pp. 289-304, p. 291.

- ↑ Michael Mende: Early industrial drive technology - wind and water power . In: Ullrich Wengenroth (Hrsg.): Technology and economy . VDI-Verlag, Düsseldorf 1993, pp. 289-304, pp. 292 f.

- ^ Hermann-Josef Wagner, Jyotirmay Mathur: Introduction to Wind Energy Systems Basics. Technology and Operation . Berlin / Heidelberg 2013, p. 1.

- ^ A. Hina Fathima, K. Palanisamy: Optimization in micro grids with hybrid energy systems - A review . In: Renewable and Sustainable Energy Reviews , 45, 2015, pp. 431–446, p. 431, doi: 10.1016 / j.rser.2015.01.059 .

- ^ Paul Gipe: Darrieus and His Vertical-Axis Wind Turbines (VAWTs). In: wind-works.org. July 20, 2017. Retrieved August 28, 2019 .

- ↑ Aleida Assmann, Frank Hiddemann, Eckhard Schwarzenberger: Company Topf & Sons - Manufacturers of Ovens for Auschwitz: A Factory Site as a Place of Remembrance? Campus Verlag, 2002, ISBN 3-593-37035-2 , p. 41 ff, under “Wind power for Wehrbauern” for details on wind energy in Weimar

- ↑ Walther Schieber: Energy source wind power . Berlin 1941

- ^ M. Heymann: History of the use of wind energy: 1890-1990 . Campus Verlag, Frankfurt 1995 (also Diss. German Museum Munich)

- ^ The Wind Energy Pioneers: The Gedser Wind Turbine . Danish Wind Energy Agency. Retrieved March 28, 2014.

- ↑ Robert Gasch , Jochen Twele (Ed.): Wind power plants. Basics, design, planning and operation. Springer, Wiesbaden 2013, p. 34.

- ↑ Erich Hau: Wind power plants: Basics, technology, use, economy. Springer-Verlag, 2008, ISBN 3540721509 .

- ↑ Aktuell '92 - Lexikon der Gegenwart . ISBN 3-611-00222-4 , p. 424.

- ↑ The first German offshore wind farm cracked the billion mark . In: ingenieur.de , February 25, 2014; accessed on February 17, 2015.