Power-to-gas

Power-to-Gas ( PtG or P2G for short , freely translated: 'Electrical energy to gas') is an energy management concept (or a technology ) according to which a fuel gas is produced using water electrolysis and electrical power . This fuel gas (usually hydrogen , possibly ammonia , methane ) can be stored for later use. Among other things, it can be used in the form of power-to-fuel in the transport sector (especially as fuel for ships and aircraft ), serve as a chemical raw material (usually referred to as power-to-chemicals ) or temporarily stored in the gas infrastructure for later reconversion in gas-fired power plants become. In addition, there are also concepts for integrated storage power plants based on reversible fuel cells, which, with electricity-to-electricity storage efficiencies of up to 70%, promise significantly higher overall efficiencies than previously existing power-to-gas storage processes.

Power-to-gas is a so-called power-to-X technology, with power denoting the temporary excess electricity required and the X the form of energy or the purpose into which the electrical energy is converted. Power-to-gas is viewed as a seasonal long-term storage system that is less efficient than the direct utilization of surplus electricity in the heating sector or transport ( power-to-heat , vehicle-to-grid ) via sector coupling or as short-term storage. Therefore, for reasons of efficiency, these technologies should be used earlier than long-term storage facilities such as gas production. It is assumed that the power-to-gas technology with the current state of the art will only be required in the third phase of the energy transition, when the share of renewable energies in the electricity mix reaches 60 to 70% and more; other sources give 80%. With lower proportions, flexibility measures in the energy system such as For example, the increased use of heat pump heating systems and electric cars , the development of smart grids , the expansion of power grids and the use of short-term storage (e.g. battery storage power plants and pumped storage power plants ) are more effective and sensible alternatives. A use of power-to-gas for energy transport, e.g. B. to replace power lines with it is neither ecologically nor economically sensible due to the low level of efficiency. In this case, direct electricity transmission via high-voltage lines is preferable to power-to-gas technology because of its much higher efficiency.

The use of power-to-gas technology only makes sense in terms of energy economy and ecology if excess electricity from renewable energies is used for production. The use of gray electricity from fossil energies would multiply the emissions instead of reducing them and would therefore be energetically and ecologically counterproductive. This is why the synthesis gas produced in this way is sometimes also referred to as EE gas. Depending on the type of renewable energy used, the gas is also called wind gas , solar gas or similar; Depending on the chemical composition of the gas, "methane" or "hydrogen" is also used instead of the term "gas".

Development history

One possible definition of power-to-gas is:

"The term power-to-gas stands for a concept in which excess electricity is used to produce hydrogen using water electrolysis and, if necessary, convert it into synthetic methane in a second step using carbon dioxide (CO 2 )."

The basic concept of using electrolytically generated hydrogen as an energy carrier by means of wind energy was proposed as early as the middle of the 19th century. The Belgian professor Nollet is said to have made a corresponding proposal as early as 1840; there is evidence of a proposal from 1868. In 1874 Jules Verne wrote about a hydrogen economy . The idea was first implemented in technical terms in 1895, when the Danish wind power pioneer Poul la Cour commissioned a wind power plant with an attached electrolyzer, which supplied oxyhydrogen to light the school in Askov.

The concept received an upswing in the 20th century as a component of the desired vision of a hydrogen economy or for storing electricity generated from renewable sources as part of the energy transition. The possibility of generating methane instead of hydrogen has only been discussed since around 2009.

The semi-governmental German Energy Agency (dena) has been maintaining a strategy platform for the processes for generating RE gas since October 2011 under the title Power to Gas . In the online edition of Manager Magazin , Power-to-Gas is described as a new technology , the model of which sounds impressively simple, as there is already space for 23.5 billion standard cubic meters (m³) in the 450,000 kilometers of gas pipelines and around 47 natural gas storage facilities in Germany. Gas is said to have increased to 32.5 billion m³ by 2025 through expansions and new buildings.

Classified according to the nine-stage Technology Readiness Level scale, chemical methane production via power-to-gas systems was between stages 7 ("Prototype in use") and 8 ("Qualified system with proof of functionality in the operational area") .

As of May 2018, there were 128 research and demonstration plants in Europe in various stages of implementation or planning; 63 of them were already in operation.

In June 2020 the German federal government decided on a "national hydrogen strategy". The energy turnaround is to be advanced with the help of hydrogen through an economic policy framework and 9 billion euros in government aid.

Concepts

Classic concept

The classic power-to-gas includes the conversion of regeneratively generated electrical energy into chemical energy and its storage in the available gas network in the form of various gases. For this, water is first split into hydrogen and oxygen using electrolysers, then methanated with the addition of carbon dioxide and finally fed into the natural gas network. This fuel can then be used for various purposes: In addition to being converted back into electricity in gas-fired power plants or combined heat and power plants, it can also be used in the transport sector and for heat generation.

Gas extraction

The synthetically produced methane gas is assigned a special role in the field of renewable energies due to its storage capacity . Like conventional synthetic natural gas , it can be fed into the existing natural gas network; it enables the energy to be stored and transported to the consumer and can relieve the load on the electrical network. The starting materials for the production of this renewable energy gas are water and carbon dioxide, which in times of surplus renewable energy are converted into hydrogen by means of water electrolysis and then, if necessary, by methanation into methane, to stabilize the grid .

To increase the overall efficiency, it makes sense to also use the waste heat generated during electrolysis and methanation . This occurs in the alkaline or PEM electrolysis at a temperature level of 40 to 90 ° C or 20 to 100 ° C and can therefore, for. B. to feed into the return of heating networks , as process heat for certain industrial processes or as a heat source for swimming pools or hospitals.

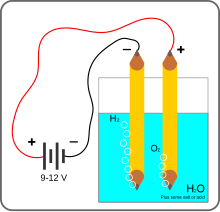

electrolysis

Hydrogen is generated by electrolysis of water and fed into the gas network as directly as possible (the maximum permissible hydrogen concentration in the German natural gas network is in the single-digit percentage range as of 2015 , around 50% hydrogen was contained in the city gas network ) or temporarily stored in large storage facilities such as salt caverns . The electrical energy required for electrolysis is generated using wind turbines or solar cells .

The following chemical reaction takes place when hydrogen is generated as RE gas by electrolysis of water:

Two water molecules (H 2 O) are split into two hydrogen molecules (H 2 ) and one oxygen molecule (O 2 ).

Alkaline electrolysers, PEM electrolysers and solid oxide fuel cells can be used for electrolysis . Further electrolysis techniques are being researched. For example, an electrolyser based on a nickel-iron accumulator was presented in 2017 , which can initially be charged and discharged like a conventional accumulator . If the accumulator reaches its capacity limit and electricity continues to be supplied, hydrogen is produced instead.

An example of the industrial implementation is the hydrogen production by Wind to Gas Energy GmbH & Co. KG on the site of the Brunsbüttel industrial park.

Methanation

Technical methanation

Alternatively, the hydrogen can be converted into methane gas together with carbon dioxide previously captured from industrial processes or extracted from the air , which is a form of the carbon capture and utilization concept. Up to 100% of the methane obtained can then be fed into the gas network or stored in gas storage facilities. In contrast to hydrogen production , in this case the complete natural gas infrastructure is available for storage and transport.

Basically, however, the production of synthetic PtG methane is nonsensical as long as hydrogen is still being obtained from fossil natural gas for material use. So far, the economy has required large amounts of hydrogen. In 2010, German industry used z. B. more than 60 TWh of hydrogen for the production of ammonia, methanol and in refineries that could be replaced by electrolysis hydrogen from renewable energies.

When methane is generated as RE gas, the following reaction takes place:

It describes the enthalpy of reaction released during this exothermic reaction . The reaction can take place according to the following two partial reactions:

- (1)

- (2)

In the first partial reaction, the hydrogen (H 2 ) generated by electrolysis initially reacts in a reverse water-gas shift reaction with carbon dioxide (CO 2 ) to form carbon monoxide (CO) and water (H 2 O). In the second partial reaction, the carbon monoxide produced in the first step reacts with additional hydrogen to form methane (CH 4 ) and again water. This second partial reaction is a variant of the Fischer-Tropsch synthesis . Since the process is exothermic, waste heat is generated. If this is used to evaporate the water in combination with high-temperature steam electrolysis, the efficiency of the entire process can be increased by around 16%.

Possible sources of carbon dioxide are power plants fired with fossil and biogenic energy sources, biogas plants, industrial processes and direct separation from the ambient air. Also sewage treatment plants offer themselves due to synergy effects, especially for municipal companies with their own fleet . However, there are two composite effects when combined with a biogas plant . On the one hand, the entry point into the natural gas network can be used jointly; on the other hand, raw biogas contains considerable amounts of CO 2 as the main component in addition to methane . The latter would have to be separated before being fed in, as is the case with the production of biomethane as biofuel . This step can be saved by methanation. The methane already present does not interfere, but traces of hydrogen sulphide , which have to be separated for this use, for example with activated carbon . An oxidative process such as that used for flue gas desulphurisation would be unsuitable, as the necessary air intake would reduce the yield.

While hydrogen as RE gas only requires electrolysis, most processes for RE gas production in the form of methane are chemical and require high pressure, high temperature, CO 2 concentration and purity.

Microbial methanation

It is possible to carry out methane synthesis in bioreactors with the help of archaea ( biological methanation ). Due to the high selectivity of the microorganisms, methanation can also take place at lower concentrations. The microbial power-to-gas process is based on the same principle as the chemical variant. The difference is that it takes place under physiological conditions and has better energy efficiency . This means that the hydrogen formed is obtained by electrolysis , just like in the chemical process . However, this happens at room temperature and neutral pH . However, the methane formation rates are lower than with the chemical variant. The problem can be countered by increasing the cathode surface area.

The process is gradual. First, enzymes are secreted that attach to the cathode surface and thus reduce the overpotential for electrolysis . Then methanogenic archaea begin to use the formed hydrogen for methanogenesis . These so-called methanogens grow both at room temperature and at higher temperatures, at which the methane formation rates are also higher. Methanogens that typically populate the reactors belong to the genera Methanobacterium Methanobrevibacter and Methanothermobacter (thermophil). Direct electron transfer has also been postulated.

A new process, which is still being developed, relocates the methanation to the fermenter of a biogas plant and uses the existing microorganisms for this. The excess amounts of CO 2 occur because the microorganisms do not find enough hydrogen. If hydrogen is generated directly in the fermenter by means of electrolysis, a methane yield of up to 95 percent can be achieved and the waste heat generated can also be used.

feed

Entry points

Renewable gas can in principle be fed into the natural gas network at any point. Since feed-in points require an appropriate infrastructure to measure the amount of gas fed in, there is also a feed-in in the area of existing or newly created gas supply structures - including gas works , gas-fired power plants , hybrid power plants , combined heat and power plants, compressor stations or gas containers called gasometers count - as entry points. Linking the feed-in with existing biogas plants is generally conceivable.

Hydrogen injection versus methanation

When implementing power-to-gas, various problems are discussed in the professional world:

The significantly higher efficiency compared to methanation speaks in favor of storage as hydrogen. With hydrogen and oxygen storage after high pressure electrolysis and a subsequent combined cycle power plant operated with oxyhydrogen gas, a mean overall electrical efficiency (electrolysis storage reconversion) of up to 50% could be demonstrated on a wind power plant . At the same time, the investment costs in the storage systems are lower, since the methanation systems can be dispensed with. The methanation also consumes energy, which is why the energy loss during reconversion in 2012 was 50 to 67 percent. In addition, the management consultancy AT Kearney states that a resulting price of 80 euros per megawatt hour for artificially produced methane would be three times as high as that of conventional natural gas. In the case of a demanding climate protection policy, it can also be assumed that only a few sources of concentrated carbon dioxide will be available in the long term. Alternatively, extraction from the air would be possible, but this is energetically complex and expensive. Catching one ton of CO 2 costs up to 500 euros.

The Federal Network Agency is of the opinion that both hydrogen as a priority at the level of the transmission network and methanation at the level of the gas distribution network have a future. The gas network operator Ontras currently sees the hydrogen proportion in gas at 2 percent due to restrictions in the applications, in particular with CNG as a fuel . The pipe system can now also tolerate higher proportions of hydrogen. The DVGW Association of the German Gas and Water Industry e. V. sees 10 percent hydrogen as uncritical. The alternative would be to receive it converted as methane after the addition of carbon dioxide.

It is controversial how high the feed-in limits for hydrogen can be. Not only possible material damage to gas lines , compressors and other gas-technical systems speak against too high a hydrogen concentration , but above all safety-related questions about avoiding an oxyhydrogen reaction . On the other hand, there has been a hydrogen network over 240 km long in the Ruhr area since 1938 . In 2010 there were more than 1,000 kilometers of hydrogen pipelines worldwide. As of 2016, Air Liquide was operating hydrogen pipelines worldwide with a total length of almost 2000 km.

In addition, the undesirable corrosion effects mainly occur with unalloyed or low-alloy steels. The steels according to DIN EN 10208-2, which are mainly used in gas pipeline construction, are less affected by this, which has been proven by several studies.

Use of the synthesis gas

| path | Efficiency | annotation |

|---|---|---|

| Electricity → gas | ||

| hydrogen | 54-72% | compressed with 200 bar |

| Methane (SNG) | 49-64% | |

| hydrogen | 57-73% | compressed at 80 bar (natural gas pipeline) |

| Methane (SNG) | 50-64% | |

| hydrogen | 64-77% | without compression |

| Methane (SNG) | 51-65% | |

| Electricity → gas → electricity | ||

| hydrogen | 34-44% | Compressed at 80 bar and 60% converted into electricity |

| Methane (SNG) | 30-38% | |

| Electricity → Gas → Electricity & Heat ( CHP ) | ||

| hydrogen | 48-62% | compressed at 80 bar and electricity / heat proportionately 40/45% |

| Methane (SNG) | 43-54% | |

There are different possible uses for hydrogen and methane. Since natural gas consists predominantly of methane, natural gas can in many cases be replaced by methane from power-to-gas systems. Power-to-gas technology can therefore be used for many applications and thus connects markets for electricity, heat and mobility with one another. In the case of hydrogen injection, the degree of utilization depends on the use of the gas, the energy required for compression and the length of the transport lines.

Generation of electrical energy

The chemical energy of RE gas can be converted into electrical energy if required . It can be converted back into electricity in different types of gas-fired power plants and combined heat and power plants. If renewable gas is used to store electricity, the efficiency of electricity to electricity is between 30% and 44%. If RE gas is converted back into electricity in combined heat and power plants, overall efficiencies of 43% to 62% can be achieved (including 45% heat share of the CHP).

warmth

Like fossil natural gas today, RE gas can theoretically be used to provide heat, for example for cooking or heating . About 35% thermal energy losses then occur for gas production. In practice, however, it would be very inefficient in terms of energy to heat buildings with RE gas and gas condensing boilers , since such a heat supply would require several times more primary electricity than the alternative use of heat pump heating . For example, a house heated by a heat pump with a heat demand of 15,000 kWh per year would require around 5,000 kWh of electrical energy with a typical annual coefficient of performance of 3. A very efficient heat pump with an annual coefficient of performance of 5 would even get by with just 3000 kWh. On the other hand, the electricity consumption when using a gas condensing boiler operated with PtG gas would be around 23,000 kWh due to the losses in gas production, which is several times higher.

mobility

Renewable gas can be used in fuel cell vehicles or to drive gas vehicles with internal combustion engines (e.g. natural gas vehicles ). One possible application of RE gas in the form of RE hydrogen will possibly be mobility in the form of fuel for fuel cell vehicles. This can be explained for the following reasons:

- In times of high energy supply, renewable hydrogen is obtained from wind or solar energy with the aim of transferring energy out of the electrical system: returning this energy to the electrical system is associated with high losses and should be avoided or bottleneck times (too few Electricity supply) are reserved.

- the prices for wind and solar power have been falling for years.

In addition to the use of gas, synthetic liquid fuels can also be considered for the mobility sector, a technology known as Power to Liquid (German: "Electrical energy to liquid"). In contrast to power-to-gas, the various power-to-liquid technologies have the production of liquid fuels such as B. target methanol . Reasons for producing liquid fuels instead of methane include: a. the low volumetric density of methane and its comparatively high global warming potential of approx. 30. Therefore, the production of methanol through the hydrogenation of carbon dioxide for the synthesis of fuels for the transport sector is considered to be a more promising technology path than the production of gaseous methane.

In the passenger car sector in particular, the large-scale use of synthetic fuels from PtG or PtL systems does not make sense, as the low overall efficiency of this system results in a far higher energy requirement than when using battery-electric vehicles. This, in turn, would require a significantly higher expansion of renewable energy systems and also result in higher costs. Fuel cell vehicles are also considered to be a possible alternative in long-distance traffic due to their high energy consumption. On the other hand, hydrogen or, alternatively, synthetic fuels obtained from it could take on the role of the most important fuel in long-distance shipping and aviation .

Integrated concept

In addition to systems that feed the synthesis gas into the gas network or make it available for end users in the transport sector, there are also concepts for integrated power-to-gas systems that temporarily store the synthesis gas in the system's own tanks or caverns and ultimately restore electrical energy (and, if necessary, heat). Feed into the public energy supply networks. These systems often have special concepts for using waste heat and thus achieve higher levels of efficiency than systems feeding into the grid.

In 2015 Jensen u. a. published a study with such a concept in the journal Energy and Environmental Science . Will be replaced by electrolysers, methanation and gas power plants for reconversion reversible working solid oxide fuel cells are used, restore the storage process in water and carbon dioxide, a methane-hydrogen mixture, and the unloading the raw materials. By operating at a relatively low temperature and high pressure, the heat required for the strongly endothermic splitting of water and carbon dioxide into hydrogen, carbon monoxide and oxygen can be used, which greatly reduces heat and thus efficiency losses during the storage process. Methane and carbon dioxide would be stored in two different underground cavern storage facilities, which could be dimensioned for a storage capacity of several months.

In the case of reconversion, fuel gas (a mixture of methane and hydrogen) pressed underground would be fed into the fuel cell after expansion, heating and mixing with water, which would generate electrical energy and an exhaust gas rich in water vapor and carbon dioxide, the latter being stored again. The hot exhaust gases from the fuel cell would be used to heat the fuel gases before they enter the fuel cell. This thermal integration of the individual system components is a key condition for the high overall efficiency of the system. In this way, according to the authors, an overall storage efficiency of up to approx. 72% can be achieved at comparatively low costs. In terms of capacity, costs and efficiency, the technology is roughly comparable to pumped storage power plants, but the storage base is chemical, making this storage the better long-term storage. The storage costs are under certain circumstances comparable to pumped storage power plants and cheaper than battery storage, compressed air storage and conventional hydrogen storage. This calculation was based on a storage power plant with an installed capacity of 250 MW of fuel cells and a storage capacity of 500 GWh (approx. 3 months). The service life of the entire system was set at 20 years, that of the fuel cells at 5 years. A study published in the trade journal Energy online-first in 2018 , which took up this concept and developed it further, came to the conclusion that with such an integrated power-to-gas concept, even electricity-to-electricity efficiencies of up to 80% are possible could.

Power-to-Chemicals

In addition to being fed into the gas network, hydrogen from renewable electricity surpluses could also serve as a raw material for the (chemical) industry and replace the hydrogen required there, which is currently still obtained from fossil sources. This is known as "power-to-chemicals". Since the chemical industry is largely based on the fossil raw materials crude oil and natural gas , the shortage of these raw materials means that the chemical industry has to convert its raw material base to renewable sources in the long term. Power-to-gas systems make it possible to use renewable surplus electricity to produce synthetic raw materials based on water and carbon dioxide, from which more complex basic materials such as methane, methanol or polymers can be produced. Power-to-chemicals are also indirectly a storage process, since in this way fossil fuels are no longer required as raw material suppliers, but are potentially available for energetic purposes. In addition, power-to-chemicals plants can make the energy system and other storage systems more flexible, for example by providing control power or by using it in load management .

The chemical industry in particular is a possible buyer of the products, but other branches of industry also have a high demand for hydrogen or other synthesis gases in some cases. For example, petroleum refineries that have a significant hydrogen requirement could be supplied with hydrogen from power-to-gas plants, which could significantly reduce the CO 2 emissions from transport . This use of power-to-gas systems has great advantages over methanation with subsequent reconversion in terms of costs and efficiency and should therefore initially be used preferentially. In the case of power-to-gas plants, the methanation step associated with additional energy losses could initially be dispensed with, while at the same time the loss-making production of hydrogen from fossil natural gas would be dispensed with. Conversely, relying too early on methanation for reconversion would mean making methane from existing eco-hydrogen with energy losses, while at the same time and with energy losses fossil hydrogen would be produced from natural gas.

Role of power-to-gas in the energy system

In the course of the energy transition , more and more variable renewable energies are being built, especially wind power and photovoltaic systems . Because at the same time conventional base load power plants are not very flexible and can only be throttled to a certain extent, there can be an oversupply of electricity during times of high wind and solar energy feed-in, especially when electricity demand is low. This effect depends on the flexibility of the conventional power plant portfolio. The higher the proportion of poorly controlled base load power plants (especially nuclear power plants and (lignite) coal power plants ), the more pronounced it is, whereas it occurs later in a flexible power plant park, which mainly consists of easily controlled gas power plants .

With a high proportion of renewable energies in the power supply, their feed-in can sometimes be higher than the demand, even without the feed-in of fossil power plants, which means that the energy must either be used, exported or regulated. Usage concepts, also known as Power-to-X , include z. B. the transformation into heat by means of power-to-heat, the use in mobility, z. B. by means of vehicle to grid or storage in storage power plants such as pumped storage , battery storage or compressed air storage power plants . These storage systems are primarily short-term storage systems, but for a full regenerative supply a long-term storage system is also required, which enables seasonal energy storage. Practically only chemical storage systems such as B. Power-to-Gas in question. At the same time, the integration of power-to-gas systems into the electrical energy supply systems, like conventional storage systems, can be used to ensure grid stability by using them as a controllable load. It must be taken into account here that electricity from renewable energies in general and electricity surpluses in particular will initially remain limited in terms of quantity for the foreseeable future. It is therefore advisable to use green electricity primarily for those processes where it can develop the greatest environmental benefit. Energy-economic analyzes showed that this is the case above all when using excess electricity for heat pumps and electric cars through sector coupling . These technologies should be used earlier than the generation of fuel gases using power-to-gas technology.

In the specialist literature, it is assumed that from a renewable energy share of around 40%, additional storage facilities are required to a greater extent; the figure 70% is also occasionally mentioned. Below a share of 40% renewable energies, compensation through thermal power plants and a slight curtailment of generation peaks from renewable energies (around 260 GWh per year or 1 per thousand of the forecasted green electricity generation with a 40% share) are considered to be economically more efficient. In this case, the storage facilities would largely be used for better utilization of lignite-fired power plants operated at base load at the expense of less emission-intensive power plants; at the same time, the costs of building the new storage facilities would significantly exceed the benefits of a more uniform power plant operation. Therefore, additional storage facilities in Germany are not considered necessary until 2020 at the earliest. Even with shares of renewable energies of up to approx. 70% of the annual electricity requirement, the storage requirement initially remains moderate, so that power-to-gas will not be needed in the foreseeable future, but can be brought to market maturity. A need for seasonal storage only arises when the share of renewable electricity generation reaches 60 to 80%. Then synthetic fuels should first be produced with power-to-gas, which if possible would only be used in transport ; only with even higher proportions would it be necessary to convert it back into electricity and thus use it in the electricity and heating sector (through combined heat and power ).

Basically, the simultaneous generation of synthetic methane using power-to-gas technology is a waste of energy as long as natural gas is used on a large scale to provide process heat and hot water. This is due to the fact that electricity for heating purposes has an efficiency of almost 100% and thus more natural gas can be saved by direct heating with electricity than renewable gas can be generated with the same amount of electricity. Therefore, when integrating excess electricity, more energy-efficient technologies such as power-to-heat should first be used and only later should the significantly more lossy power-to-gas technology be used. Since power-to-gas is also more cost-intensive than the alternatives mentioned, this sequence of use is also recommended for economic reasons. Due to the manageable degree of efficiency, which in turn leads to a considerable increase in the need for wind power and photovoltaic systems, a future energy system should be designed in such a way that there is only a low long-term storage requirement.

The use of power-to-gas only makes sense in terms of energy and saves emissions if green electricity is used. On the other hand, if electricity from fossil fuels is used, the emissions multiply. For example, if electricity is used from a lignite power station, which emits 1161 g CO 2-eq. / kWh, with 60% efficiency each for the storage process and reconversion in the combined cycle power plant, total emissions would be 3225 g CO 2 -equiv. / kWh, about eight times the amount of electricity from a fossil-fuel natural gas power plant. Under certain circumstances, however, negative emissions can be achieved with which the carbon dioxide content of the earth's atmosphere can be actively reduced. This is the case, for example, when the carbon dioxide for methanation is obtained from the air and the synthesized methane is later burned in a power plant with CO 2 separation and storage .

Situation in Germany

Storage capacity of the German natural gas network

The possibility of storing the hydrogen or methane gas in an existing natural gas network is considered to be of great importance when using RE gas.

According to the Fraunhofer Institute for Wind Energy and Energy System Technology (IWES), Germany will need storage capacities of 30 terawatt hours (TWh) to compensate for seasonal fluctuations in wind and sun in 2050 - if, according to the federal government, 80% of electricity is to come from renewable sources . In contrast, the storage capacity of the natural gas storage facilities in the German natural gas network was stated by Fraunhofer IWES in April 2010 to be over 200 TWh, which corresponds to consumption of several months. Including the cavern and pore storage facilities planned for 2013, the storage capacity of the German natural gas network is around 332 TWh. Natural gas consumption was 760 TWh in 2011, but could increase further with more power-to-gas systems. Nevertheless, the natural gas network including the planned storage facilities would be sufficiently dimensioned for a secure full supply based on renewable energies.

The German pumped storage power plants have a capacity of 0.04 TWh and are designed as short-term storage for a service life ranging from hours to days. Pumped storage plants have a significantly higher degree of efficiency (between 70% and 85%), but their economic efficiency is also determined by the considerable investment costs and the space required. The installed capacity will be expanded, but in Germany, for topographical and political reasons, it cannot be as large as the storage capacity of the natural gas network. In contrast, there is great potential for storage capacities in Northern Europe. In Norway, for example, there are reservoirs that can be used for storage hydropower plants with a potential storage capacity of around 84 TWh, in Sweden of around 34 TWh. This storage capacity is of a similar size to the storage capacity of the German gas network.

The interactive map on the German Energy Agency's Power-to-Gas strategy platform gives an overview of the power-to-gas plants in Germany .

Legal requirements

If power-to-gas systems are operated with electricity from renewable energies, RE gas falls under the definition of "storage gas" according to § 5 No. 29 EEG 2014 ( Renewable Energy Sources Act ) and "biogas" according to § 3 No. 10c EnWG ( Energy Industry Act ).

For storage gas from renewable energy, if it is then converted back into electrical energy, a feed-in tariff is paid in accordance with Section 5 No. 29 EEG 2014 . The remuneration only applies to small systems (<100 kW from January 1, 2016, previously <500 kW). For larger systems, the subsidy takes the form of a market premium in accordance with Section 5 No. 29 EEG 2014 . However, this does not represent any special support, as the detour via storage results in additional costs, but no additional profit compared to direct feed-in of the electricity, apart from the exemption from certain fees.

List of plants in Germany

| place | Installation | Power kW) | operator | comment |

|---|---|---|---|---|

| Stuttgart | 2009 | 25th | IWES / ETOGAS | The world's first pilot plant with an output of 25 kW for the production of methane using the power-to-gas process was set up in November 2009 in Stuttgart at the Center for Solar Energy and Hydrogen Research Baden-Württemberg (ZSW) with the participation of the Fraunhofer Institute for wind energy and energy system technology (IWES) and the company SolarFuel (today ETOGAS GmbH ) put into operation. The system demonstrated the basic feasibility of the process; the CO 2 was taken from the ambient air. The basic technical development was carried out by the research institutes ZSW (Center for Solar Energy and Hydrogen Research, Stuttgart) and Fraunhofer IWES (Kassel). The efficiency of gas production is around 40%. |

| Morbach | 2011 | 25th | juwi / ETOGAS | In March 2011, the 25 kW power-to-gas system from juwi and SolarFuel (now ETOGAS) was installed in the Morbach energy landscape in the Hunsrück and tested there for a few weeks. This test combined a wind gas plant, a wind farm and a biogas plant. |

| Bad Hersfeld | 2012 | 25th | IWES / ETOGAS | In 2012, the 25 kW power-to-gas plant was operated for several months at a biogas plant at the Hessian biogas research center. In the pilot test that the Fraunhofer Institute for Wind Energy and Energy System Technology (IWES) and the SolarFuel company (today ETOGAS) carried out together with the states of Hesse and Thuringia, the direct conversion of the carbon dioxide contained in the biogas into methane was demonstrated. |

| Stuttgart | 2012 | 250 | ZSW, IEWS, ETOGAS | In October 2012, a 250 kW power plant ten times as large - at the time the world's largest power-to-gas plant - went into operation at the ZSW in Stuttgart. The system was built as part of a project funded by the BMU with the project partners ZSW, IWES and SolarFuel (today ETOGAS) in the ZSW technical center as a PtG test system with electrolysis (250 kW electrical connection power) and several methanation variants. |

| Prenzlau | 2012 | 500 | Yield |

The company Enertrag operates a pilot plant, a hybrid power plant that went into normal operation in March 2012 in the Uckermark north of Prenzlau (Brandenburg), which uses hydrogen as an intermediate storage facility. The system, which went into operation for the first time in October 2011, is fed by a total of three wind turbines with two megawatts each. The power of the electrolyzer is 500 kW with an efficiency of around 75%. The energy supplier Greenpeace Energy has been offering a wind gas subsidy tariff since October 1, 2011, which includes a subsidy of 0.4 euro cents per kilowatt hour for 5 wind gas systems for the delivery of conventional natural gas and is subsidized by over 19,000 customers (2018). Since Greenpeace Energy does not have an electrolyser, the company signed a purchase agreement in January 2012 for the purchase of hydrogen from the company Enertrag. After initial contract problems and start-up difficulties, the feed-in of "wind gas" into the gas network began on December 12, 2014 by the Enertrag pilot plant in the Uckermark . At the end of 2012, the supervisory board initially unanimously rejected plans to set up Greenpeace's own plant to generate wind gas. The background to this is the current full remuneration and the EEG compensation payments also for non-feedable wind peak load electricity, which at least from an economic point of view does not make wind gas systems absolutely necessary for energy producers and runs counter to the wind gas concept. But Greenpeace Energy plans to build its own electrolysis plant in 2015. The plant is also the supplier of a wind hydrogen filling station for Total Deutschland GmbH in Heidestrasse in Berlin-Mitte, which was put into operation on April 18, 2012 as part of the Clean Energy Partnership (CEP) hydrogen project and is designed for 38 refueling per day. |

| Werlte | 2013 | 6000 | Audi / ETOGAS | On behalf of Audi AG , ETOGAS GmbH built an industrial pilot plant for converting excess green electricity into renewable natural gas, known by Audi as "e-gas", in addition to an existing biogas plant in Werlte . In addition to hydrogen obtained from regenerative sources, regenerative CO 2 from a biogas processing plant supplied by MT-Biomethan is used for methanation . The plant with an electrical connection capacity of 6 MW will produce 1.4 million standard cubic meters of natural gas standard quality per year. The plant was inaugurated on June 25, 2013 and completed its trial operation in autumn 2013. As part of Audi's e-gas project, the system produces renewable fuel for the Audi brand's first CNG model, the Audi A3 Sportback g-tron. The gas production efficiency is 54%. |

| Schwandorf | 2013 | 208 | MicrobEnergy | In February 2013 , the Viessmann Group company MicrobEnergy GmbH put a research facility into operation in Schwandorf / Upper Palatinate, which uses a microbiological process to methanate the hydrogen. The 21.3 m³ of hydrogen produced per hour in the electrolyser produce an average of 5.3 m³ / h of methane.

A second MicrobEnergy system has been under construction since July 2013. At the Schwandorf-Wackersdorf waste water treatment plant, an electrolyser generates 30 m³ / h of hydrogen, which is microbiologically converted into 7.5 m³ / h of methane in a 1300 cubic meter digestion tower. In addition to the Schwandorf waste water treatment plant, the project partner is the Research Center for Energy Networks and Energy Storage (FENES) of the Regensburg University of Technology. |

| Allendorf (Eder) | 2015 | 300 | MicrobEnergy /

Carbotech / Viessmann |

Biological methanation , Allendorf (Eder) plant

The system was relocated from Schwandorf to the Allendorf (Eder) location. Since the beginning of March 2015, electricity has been converted into methane and fed into the public natural gas network. The CO 2 required comes from the exhaust gas flow of a nearby biomethane plant with gas processing or raw biogas from this plant with around 50% CO 2 content is used for biological methanation . In this case, the power-to-gas process also serves as a processing technology for raw biogas from biogas or sewage treatment plants. As part of a cooperation, the storage gas from the power-to-gas plant is marketed to Audi. |

| Falkenhagen | 2013 | 2000 | E.ON | In Falkenhagen in Prignitz, Brandenburg, the energy company E.ON first fed hydrogen generated from wind power into the natural gas network in a test run of a pilot plant in June 2013. In total, around 160 cubic meters of hydrogen were generated and fed in during the one-hour test. This is the first time that E.ON has successfully implemented the entire process chain from power consumption to feeding in the hydrogen.

The pilot plant was put into operation at the end of August 2013. According to E.ON, the system uses alkali electrolysis to produce around 360 standard cubic meters of hydrogen per hour. |

| Werder | 2013 | 1000 | Wind project |

WIND-projekt built an electrolysis plant with a planned output of 1000 kW in the Werder / Kessin wind farm . |

| Frankfurt am Main | 2014 | 320 | Thüga | From 2014 to 2017 , the Thüga Group operated the world's first power-to-gas demonstration plant at the Frankfurt am Main site , which converted electricity into hydrogen and fed it into the municipal gas distribution network. A proton exchange membrane (PEM) generated 60 m³ of hydrogen per hour. |

| Mainz | 2015 | 3 × 1300 | Mainz municipal utilities | In July 2015, an electrolyser with an output of 6 MW was put into operation in the Mainz energy park, which is considered to be the world's largest power-to-gas plant to date. The hydrogen produced is partly fed into the gas network and partly delivered to hydrogen filling stations. The research project was funded by the Federal Ministry of Economics, among others. The RheinMain University of Applied Sciences as well as Siemens , Linde and the Mainzer Stadtwerke are involved . |

| Ibbenbueren | 2015 | 150 | RWE | In August 2015, the energy company RWE started feeding hydrogen generated by wind power into the regional gas network. The hydrogen is obtained by means of PEM electrolysis in a power-to-gas plant in Ibbenbüren in North Rhine-Westphalia . The plant has a capacity of 150 kW and an efficiency (electricity to hydrogen) of 86%. |

| Hassfurt | 2016 | 1250 | Greenpeace Energy / Städtischen Betriebe Haßfurt | The municipal companies in Haßfurt and the nationwide active eco-energy provider Greenpeace Energy operate a commercial wind gas plant in Haßfurt. Since September 8, 2016, this has been feeding around one million kWh of hydrogen per year into the gas network, which is generated using excess electricity from renewable energies. For this purpose, a container-sized 1.25 megawatt PEM electrolyser is used in the facility in the port area on the Main . In order to be able to generate the gas with the surplus wind power as economically as possible, the system is integrated into the virtual power plant of the Cologne energy company Next Kraftwerke. This only switches on the PEM electrolyser via a remote control unit when the electricity exchange price is particularly low - for example in stormy weather conditions such as at the beginning of 2017. |

| Lampoldshausen | ? | 1000 | German Aerospace Center | In 2016, DLR began building a hydrogen- producing power-to-gas facility at the Institute for Space Propulsion for the research and development of this storage technology on an industrial scale. In addition to a PEM electrolyser with an output of 1 MW, the system also includes a block-type thermal power station that can be operated with the hydrogen produced in order to fully supply the institute with electricity and heat when there is little electricity generated from wind power and photovoltaic systems . Part of the hydrogen is to be used for research on rocket engines at the site. |

| Dresden | 2017 | 15 - 60 | HELMETH project |

As part of the European HELMETH research project, work began in 2014 on developing a new power-to-gas concept. This stands out due to the hydrogen production using pressure-operated high-temperature electrolysis (SOEC). The subsequent CO 2 methanation is equipped with boiling water cooling and thus produces the steam required for electrolysis. Due to the energetic link between the two modules, there is the potential to achieve significantly higher levels of efficiency than before. An efficiency of 76% with a potential increase to 80% on an industrial scale is stated for the prototype. More detailed explanations can be found in the chapter European research project HELMETH |

| Grenzach-Wyhlen | 2018 | 300-1000 | EnergieDienst AG | The plant was designed to demonstrate the profitability of power-to-gas technology. Since the electricity for hydrogen generation is obtained from a neighboring hydropower plant on the Rhine, there are no network charges and the EEG surcharge. In addition, the use of hydropower allows more full-load hours than wind or solar energy. |

| Sonneberg | 2018 | Sonneberg waterworks | To build up a regional hydrogen economy, a pressure electrolyser is used in the Sonneberg-Heubisch sewage treatment plant to generate hydrogen from renewable energies. The modular design of the alkaline pressure electrolyser with modules in the power range of 75 kW is well suited for decentralized dynamic use in connection with fluctuating renewable energies. |

Planned plants and other projects

European research project HELMETH

In April 2014, funded by the EU and the was Karlsruhe Institute of Technology coordinated (KIT) research project HELMETH (Integrated H igh-Temperature EL ectrolysis and METH Anation for Effective Power to Gas Conversion) started. In addition to the KIT, the following are involved: Politecnico di Torino (POLITO), Sunfire GmbH, European Research Institute of Catalysis (ERIC), EthosEnergy Italia (EEI), National Technical University of Athens (NTUA) and the German Association for Gas and Water (DVGW) . The aim of the EU project is to demonstrate the feasibility of a highly efficient power-to-gas process with thermal integration of high temperature electrolysis ( SOEC ) and CO 2 methanation. The thermal integration of exothermic methanation and evaporation for water vapor electrolysis means that efficiencies of over 85% (calorific value of the methane generated in relation to the electrical energy used) are theoretically possible. The project was completed at the end of 2017 and achieved an efficiency of 76% for the prototype with a stated potential of 80% for systems on an industrial scale. The operating conditions of the CO 2 methanation are a gas pressure of 10 - 30 bar, an SNG production of 1 - 5.4 m 3 / h (NTP) and an educt conversion of the SNG with H 2 <2 vol .-% or CH 4 > 97 vol .-% produced. This means that the natural gas substitute generated could be fed into the entire German natural gas network without restrictions. Boiling water at up to 300 ° C is used as the cooling medium for the exothermic reaction, which corresponds to a water vapor pressure of around 87 bar. The SOEC works with a pressure of up to 15 bar, steam conversions of up to 90% and generates one standard cubic meter of hydrogen from 3.37 kWh of electricity as a raw material for methanation.

European research project STORE & GO

The level of technological maturity of power-to-gas for everyday use is being tested in the STORE & GO research project funded by the European Union . For this purpose, three different methanation concepts are being set up and operated at three European locations ( Falkenhagen / Germany , Solothurn / Switzerland , Troia / Italy ). The technologies used include biological and chemical methanation and the extraction of CO 2 directly from the atmosphere. The methane generated is fed directly into existing gas networks or liquefied into bio- LNG , depending on the location. The overriding goal is to evaluate the technologies used and possible applications under technical, economic and regulatory aspects. Since March 2016, the 27 project partners want to examine not only the technology, but also specific future application scenarios and business models for a period of four years. The project is funded by the EU's “ Horizon 2020 ” research program with € 18 million and the Swiss government with € 6 million. The industrial project partners contribute a further € 4 million. The project coordinator is the research center of the German Gas and Water Association (DVGW) at the Karlsruhe Institute of Technology (KIT).

Further planning for power-to-gas systems

In 2018 it became known that a consortium consisting of Tennet , Gasunie and Thyssengas wanted to gradually build a power-to-gas plant with a capacity of 100 MW in northern Lower Saxony. Weener and Wiefelstede are under discussion as the location of the plant . The plan is for the first module to go into operation in 2022, followed by another every two years. The plant is to be completed in 2028. The costs are put in the low three-digit million range.

Another user of power-to-gas technology is Sunfire.

According to Manager Magazin, Enercon and some municipal utilities are also interested in power-to-gas technology. As an argument for the fact that gas suppliers are now also interested in the technology, among other things, the declining gas demand for heating due to improved insulation of buildings is cited.

Systems outside of Germany

Underground Sun Storage in Pilsbach, Austria

In Austria, a research project was started in 2014 in which methane gas generated using power-to-gas technology was fed directly into an underground pore gas storage facility and an admixture of up to 10% hydrogen gas was tested. The research project was successfully completed in 2016. As a follow-up project, underground sun conversion was started in March 2017 . One would like to generate and store hydrogen and CO 2 generated from power-to-gas as well as a microbiological process directly underground.

Supply of Utsira in Norway

From 2004 to 2008, ten households on the Norwegian island of Utsira were supplied with electricity by wind turbines and a storage system consisting of an electrolyser, pressure accumulator, fuel cell and hydrogen turbine.

Plants in Denmark

The University of Aarhus , the electricity company of the City of Zurich (ewz), Erdgas Zürich , other Danish and German actors are committed to a demonstration plant in the Danish city of Foulum .

Currently (2016) one of the most modern hydrogen plants in Europe is being built in Hobro , which should be completed by 2017. The "Proton Exchange Membrane" process is used here for electrolysis. The system can be started up within seconds. Six different companies are involved in the Danish “HyBalance” project (including Air Liquide ) that want to develop business models based on power-to-gas.

GRHYD demonstration project in Dunkerque, France

An industrial consortium consisting of GDF Suez and Areva , among others, is planning a filling station in Dunkerque for a liquid fuel with up to 20% hydrogen, and the other is to feed hydrogen into the gas distribution network.

Aarmatt hybrid plant in Zuchwil, Switzerland

The Regio Energie Solothurn has a "hybrid plant" in Zuchwil ( Canton Solothurn ) that connects electricity, gas and heating networks. The system is part of the pan-European research project STORE & GO . The system was put into operation in 2015 and has the following technical components:

- A 6 MW gas boiler (92% efficiency) that feeds heat directly into the district heating network in emergency and peak load situations .

- The block-type thermal power station (electrical output 1.2 MW, heating output 1.2 MW) consists of a twelve-cylinder gas engine and a generator connected to it; the degree of utilization is 90% (44% electrical / 46% thermal). The heat can be fed into the district heating network of Regio Energie Solothurn and the electricity can be used flexibly.

- The electrolyser (power consumption: 2 × 175 kWel) splits off the hydrogen by means of a proton exchange membrane (output hydrogen: 60 Nm3 / h, efficiency 50–60%) and stores it in pressure cylinders. The Regio Energie Solothurn uses excess electricity from renewable energy for this purpose.

- The hydrogen storage (usable volume approx. 7.5 m³, operating pressure up to 200 bar, max. 1500 Nm3 H2 at 3.5 kWh / Nm3 = 5.3 MWh) stores and mixes it with 5 to 200 Nm3 / h in the gas network.

- Three heat storage units of 100m3 each (storage capacity 3 × 5.5 MWh, charging / discharging capacity 6 MW). These are used as tip breakers, especially during cold winter days.

In 2019, an additional methanation plant was put into operation.

Pilot and demonstration plant in Rapperswil, Switzerland

The Institute for Energy Technology at the University of Applied Sciences in Rapperswil ( Canton St. Gallen ) operated the first power-to-methane plant in Switzerland from 2014 to 2017. The pilot and demonstration plant used energy from photovoltaics to generate methane gas from water and CO 2 obtained from the ambient air. It achieved an efficiency of 35%. The methane generated could be filled directly into suitable vehicles at an integrated filling station. In addition, the plant was connected to the local natural gas network.

See also

- Alternative fuels

- Power-to-ammonia

- BtL fuel ("fuel from biomass")

- CtL fuel ( Coal to Liquid )

- GtL fuel ( gas to liquid )

- XtL fuel ( X to Liquid )

- Methanol economy

literature

- Michael Sterner , Ingo Stadler (ed.): Energy storage. Need, technologies, integration. 2nd edition, Berlin Heidelberg 2017, ISBN 978-3-662-48893-5 .

- Michael Sterner: Bioenergy and renewable power methane in integrated 100% renewable energy systems . Limiting global warming by transforming energy systems. Ed .: Jürgen Schmidt. kassel university press, Kassel 2009, ISBN 978-3-89958-798-2 , 4. Renewable Power Methane - solution for renewable power integration and energy storage, p. 104–126 ( online as PDF; 17.7 MiB [accessed on December 1, 2012] also: dissertation at the University of Kassel 2009).

- Gerda Gahleitner, Hydrogen from renewable electricity: An international review of power-to-gas pilot plants for stationary applications. In: International Journal of Hydrogen Energy 38, Issue 5, (2013), 2039-2061, doi: 10.1016 / j.ijhydene.2012.12.010 .

- Alberto Varone, Michele Ferrari, Power to liquid and power to gas: An option for the German Energiewende. In: Renewable and Sustainable Energy Reviews 45, (2015), 207–218, doi: 10.1016 / j.rser.2015.01.049 .

- Manuel Götz, Jonathan Lefebvre, Friedemann Mörs, Amy McDaniel Koch, Frank Graf, Siegfried Bajohr, Rainer Reimert, Thomas Kolb, Renewable Power-to-Gas: A technological and economic review. In: Renewable Energy 85, (2016), 1371-1390, doi: 10.1016 / j.renene.2015.07.066 .

Web links

- Power to Gas strategy platform

- German Energy Agency (Ed.): Technical brochure: Power to Gas. An innovative system solution on the way to market readiness. (PDF; 2.6 MB, 13 pages) As of December 2013

- German Energy Agency (Ed.): Key issues paper of the Power to Gas strategy platform. The contribution of Power to Gas to achieving the energy policy objectives in the context of the energy transition. (PDF; 0.8 MB, 6 pages) Berlin, November 4, 2013

Individual evidence

- ↑ a b c d e f Michael Sterner, Mareike Jentsch, Uwe Holzhammer: Energy-economical and ecological evaluation of a wind gas offer. (PDF; 2 MB) Expert report by the Fraunhofer Institute for Wind Energy and Energy System Technology (IWES) Kassel on behalf of Greenpeace Energy. In: greenpeace-energy.de. February 2011, accessed April 9, 2019 .

- ↑ Alberto Varone, Michele Ferrari, Power to liquid and power to gas: An option for the German Energiewende. In: Renewable and Sustainable Energy Reviews 45, (2015), 207–218, p. 209, doi: 10.1016 / j.rser.2015.01.049 .

- ↑ a b c S.H. Jensen et al .: Large-scale electricity storage utilizing reversible solid oxide cells combined with underground storage of CO2 and CH4 . In: Energy and Environmental Science . tape 8 , no. 8 , 2015, p. 2471-2479 , doi : 10.1039 / c5ee01485a .

- ^ Zhan Gao et al .: A perspective on low-temperature solid oxide fuel cells . In: Energy and Environmental Science . tape 9 , no. 5 , 2016, p. 1602-1644 , doi : 10.1039 / C5EE03858H .

- ↑ See Peter D. Lund u. a., Review of energy system flexibility measures to enable high levels of variable renewable electricity. In: Renewable and Sustainable Energy Reviews 45, (2015), 785-807, doi: 10.1016 / j.rser.2015.01.057 .

- ^ Cf. Brian Vad Mathiesen , Henrik Lund : Comparative analyzes of seven technologies to facilitate the integration of fluctuating renewable energy sources . In: IET Renewable Power Generation . tape 3 , no. 2 , 2009, p. 190–204 , doi : 10.1049 / iet-rpg: 20080049 .

- ↑ See also André Sternberg, André Bardow: Power-to-What? - Environmental assessment of energy storage systems . In: Energy and Environmental Science . tape 8 , 2015, p. 400 , doi : 10.1039 / c4ee03051f .

- ↑ a b c d Hans-Martin Henning , Andreas Palzer, Carsten Pape, Frieder Borggrefe, Henning Jachmann and Manfred Fischedick: Phases of the Transformation of the Energy System ( PDF file ) In: Energiewirtschaftliche Tagesfragen 65, Heft 1/2, (2015), Pp. 10-13.

- ↑ a b Stefan Weitemeyer, David Kleinhans, Thomas Vogt, Carsten Agert, Integration of Renewable Energy Sources in future power systems: The role of storage. In: Renewable Energy 75, (2015), 14-20, doi: 10.1016 / j.renene.2014.09.028 .

- ↑ See Volker Quaschning , Regenerative Energiesysteme. Technology - calculation - simulation . 9th updated edition. Munich 2015, p. 384.

- ↑ Michael Sterner , Ingo Stadler (Ed.): Energy storage. Need, technologies, integration. 2nd edition, Springer Verlag, Berlin Heidelberg 2017, p. 465.

- ^ Federal Network Agency - definition of power-to-gas. Retrieved April 14, 2012 .

- ↑ Cf. Matthias Heymann : The history of the use of wind energy 1890–1990. Frankfurt / New York 1995, p. 54.

- ↑ Volker Quaschning: Renewable energies and climate protection . Munich 2013, p. 323.

- ^ Matthias Heymann: The history of the use of wind energy 1890-1990. Frankfurt am Main / New York 1995, pp. 64-66.

- ↑ Strategy platform Power to Gas. In: dena.de. Retrieved September 18, 2019 .

- ↑ a b c d Sarah Sommer: Lobby wants to store green electricity in the gas network. In: manager-magazin.de. March 26, 2012, accessed April 12, 2020 .

- ↑ Michael Sterner , Ingo Stadler (Ed.): Energy storage. Need, technologies, integration. 2nd edition, Springer Verlag, Berlin Heidelberg 2017, p. 663.

- ↑ Christina Wulf et al .: Review of Power-to-Gas Projects in Europe . In: Energy Procedia . tape 155 , 2018, p. 367–378 , doi : 10.1016 / j.egypro.2018.11.041 .

- ↑ Bernhard Pötter: The Government's Hydrogen Strategy: A Hundred Times More by 2030 . In: The daily newspaper: taz . June 10, 2020, ISSN 0931-9085 ( taz.de [accessed June 12, 2020]).

- ↑ a b c Ulrich Eberle, Rittmar von Helmolt, Sustainable transportation based on electric vehicle concepts: a brief overview . In: Energy and Environmental Science 3, Issue 6, (2010), 689-699, doi: 10.1039 / C001674H .

- ↑ Michael Sterner, Ingo Stadler: Energy storage - requirements, technologies, integration . Berlin - Heidelberg 2014, especially p. 334.

- ↑ Petra Nitschke-Kowsky, Werner Weßing, Holger Dörr, Kerstin Kröger: Practical experience with feeding hydrogen into a natural gas distribution network . In: energy | water practice . No. 10/2015 . Wirtschafts- und Verlagsgesellschaft Gas und Wasser mbH, October 2015, ISSN 1436-6134 , p. 20 ( dvgw.de [PDF; 671 kB ; accessed on July 12, 2018]). dvgw.de ( Memento of the original from July 17, 2018 in the Internet Archive ) Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice.

- ↑ Gerda Gahleitner, Hydrogen from renewable electricity: An international review of power-to-gas pilot plants for stationary applications. In: International Journal of Hydrogen Energy 38, Issue 5, (2013), 2039-2061, 2048, doi: 10.1016 / j.ijhydene.2012.12.010 .

- ↑ Lars Klaaßen: A classic is taking off . In: The daily newspaper: taz . April 13, 2019, ISSN 0931-9085 , p. 29 ePaper, Berlin 31 Alle, Nord ( taz.de [accessed June 11, 2019]).

- ^ FM Mulder et al .: Efficient electricity storage with the battolyser, an integrated Ni-Fe-battery and electrolyser . In: Energy and Environmental Science . tape 10 , no. 3 , 2017, p. 756-764 , doi : 10.1039 / C6EE02923J .

- ^ Dierk Jensen: Green gas in the chemical park . In: The daily newspaper: taz . September 7, 2019, ISSN 0931-9085 , p. 27 ePaper, Berlin 29 Alle, Nord ( taz.de [accessed on March 2, 2020]).

- ↑ Michael Sterner, Ingo Stadler: Energy storage - requirements, technologies, integration . Berlin - Heidelberg 2014, p. 423.

- ↑ Cf. Viktor Wesselak , Thomas Schabbach , Thomas Link, Joachim Fischer, Handbuch Regenerative Energietechnik , 3rd updated and expanded edition, Berlin / Heidelberg 2017, p. 763.

- ↑ a b c Michael Sterner: Bioenergy and renewable power methane in integrated 100% renewable energy systems . Limiting global warming by transforming energy systems. Ed .: Jürgen Schmidt. kassel university press, Kassel 2009, ISBN 978-3-89958-798-2 , 4. Renewable Power Methane - solution for renewable power integration and energy storage, p. 104–126 ( online as PDF; 17.7 MiB [accessed on December 1, 2012] also: dissertation at the University of Kassel 2009). Online as PDF; 17.7 MiB ( Memento of the original dated December 2, 2011 in the Internet Archive ) Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice.

- ↑ Georg Fuchs, Benedikt Lunz, Matthias Leuthold, Uwe Sauer: Technology Overview on Electricity Storage . Overview on the potential and on the deployment perspectives of electricity storage technologies. Aachen June 2012, p. 36 ( online as PDF; 886 KiB [accessed on September 9, 2015]).

- ^ "Power to Gas" demonstration system from the Thüga Group. ( Memento of the original of July 12, 2018 in the Internet Archive ) Info: The archive link was automatically inserted and not yet checked. Please check the original and archive link according to the instructions and then remove this notice. DENA website. Retrieved July 24, 2013.

- ↑ Michael Sterner, Ingo Stadler: Energy storage - requirements, technologies, integration . Berlin - Heidelberg 2014, p. 420.

- ↑ Alexander Krajete pitches Bio Power Storage Cleantech Startup Greenthitan. Lecture at EcoSummit in March 2011 (English) .

- ↑ VDI nachrichten No. 18: Technology & Finances. May 6, 2011.

- ↑ Fuel - Sun in the tank. In: wiwo.de . May 4, 2011, accessed January 26, 2020 .

- ↑ Michael Siegert, Matthew D. Yates, Douglas F. Call, Xiuping Zhu, Alfred Spormann, Bruce E. Logan: Comparison of Nonprecious Metal Cathode Materials for Methane Production by Electromethanogenesis. In: ACS Sustainable Chemistry & Engineering . 2, 2014, p. 910, doi: 10.1021 / sc400520x .

- ↑ Jörg S. Deutzmann, Merve Sahin, Alfred M. Spormann: Extracellular Enzymes Facilitate Electron Uptake in Biocorrosion and Bioelectrosynthesis. In: mBio. 6, 2015, pp. E00496 – e15, doi: 10.1128 / mBio.00496-15 .

- ^ Matthew D. Yates, Michael Siegert, Bruce E. Logan: Hydrogen evolution catalyzed by viable and non-viable cells on biocathodes. In: International Journal of Hydrogen Energy . 39, 2014, p. 16841, doi: 10.1016 / j.ijhydene.2014.08.015 .

- ↑ Pascal F. Beese-Vasbender, Jan-Philipp Grote, Julia Garrelfs, Martin Stratmann, Karl JJ Mayrhofer: Selective microbial electrosynthesis of methane by a pure culture of a marine lithoautotrophic archaeon. In: Bioelectrochemistry. 102, 2015, p. 50, doi: 10.1016 / j.bioelechem.2014.11.004 .

- ↑ Michael Siegert, Matthew D. Yates, Alfred M. Spormann, Bruce E. Logan: Methanobacterium dominates biocathodic archaeal communities in methanogenic microbial electrolysis cells. In: ACS Sustainable Chemistry & Engineering . 3 (7), 2015, p. 1668, doi: 10.1021 / acssuschemeng.5b00367 .

- ↑ Michael Siegert, Xiu-Fen Li, Matthew D. Yates, Bruce E. Logan: The presence of hydrogenotrophic methanogens in the inoculum improves methane gas production in microbial electrolysis cells. In: Frontiers in Microbiology. 5, 2015, doi: 10.3389 / fmicb.2014.00778 .

- ↑ Kozo Sato, Hideo Kawaguchi, Hajime Kobayashi: Bio-electrochemical conversion of carbon dioxide to methane in geological storage reservoirs. In: Energy Conversion and Management . 66, 2013, p. 343, doi: 10.1016 / j.enconman.2012.12.008 .

- ↑ Shaoan Cheng, Defeng Xing, Douglas F. Call, Bruce E. Logan: Direct Biological Conversion of Electrical Current into Methane by Electromethanogenesis. In: Environmental Science & Technology . 43, 2009, p. 3953, doi: 10.1021 / es803531g .

- ↑ New power-to-gas process: electrolysis directly in the biogas plant. On: scinexx.de. 20th September 2013.

- ↑ Ulrich Wernekinck: Gas measurement and gas billing. 3. Edition. DVGW practical knowledge, ISBN 3-8027-5617-7 , p. 129.

- ↑ online in researchgate Dan Gao, Dongfang Jiang, Pei Liu, Zheng Li, Sangao Hu, Hong Xu: An integrated energy storage system based on hydrogen storage: Process configuration and case studies with wind power In: Energy 66, (2014), 332 –341, doi: 10.1016 / j.energy.2014.01.095 .

- ↑ a b Examination of the consistency of climate policy and the costs of methanation strategies . Eco Institute . Retrieved July 27, 2014.

- ↑ a b The energy impulse - a contribution to the debate for the next phase of the energy transition. (PDF; 1.5 MB) In: dvgw.de. DVGW , May 2017, accessed April 30, 2019 .

- ↑ Transport of hydrogen (source: TÜV Süd)

- ↑ Hydrogen Pipelines. (XLS; 54 KB) In: h2tools.org. Pacific Northwest National Laboratory , 2016, accessed October 17, 2019 (direct file download).

- ↑ Jens Hüttenrauch, Gert Müller-Syring: Adding hydrogen to natural gas . In: Energy Water Practice . No. 10 , 2010, p. 68–71 ( online as PDF , 176 KiB [accessed November 2, 2013]).

- ↑ Volker Quaschning : Renewable energies and climate protection . Munich 2018, pp. 112–115.

- ↑ 2nd VDI Conference Stationary Energy Storage for Renewable Energies, June 20 and 21, 2012, Karlsruhe, 6 pages. (PDF; 162 kB) Retrieved July 13, 2013 .

- ↑ Ahmed Al-Mamoori et al .: Carbon Capture and Utilization Update . In: Energy Technology . tape 5 , 2017, p. 834–849 , doi : 10.1002 / duck.201600747 .

- ↑ German Advisory Council on Environmental Issues 2017: Change of direction necessary: Climate protection in the transport sector. Special report, p. 59. Accessed June 7, 2020.

- ↑ Volker Quaschning : Renewable energies and climate protection. 4th edition, Munich 2018, pp. 116f.

- ^ Siavash Khalili et al .: Global Transportation Demand Development with Impacts on the Energy Demand and Greenhouse Gas Emissions in a Climate-Constrained World . In: Energies . tape 12 , no. 20 , 2019, pp. 1.52, here: p. 42 , doi : 10.3390 / en12203870 .

- ↑ Giacomo Vutera et al .: A novel system for large-scale storage of electricity as synthetic natural gas using reversible pressurized solid oxide cells . In: Energy . tape 166 , 2018, p. 738-754 , doi : 10.1016 / j.energy.2018.10.079 .

- ↑ Michael Sterner, Ingo Stadler: Energy storage - requirements, technologies, integration . Berlin - Heidelberg 2014, p. 729.

- ↑ Michael Sterner, Ingo Stadler: Energy storage - requirements, technologies, integration . Berlin - Heidelberg 2014, p. 33.

- ↑ Robert Schlögl : Learning from nature. Chemical reduction of CO 2 . In: Jochem Marotzke , Martin Stratmann (Hrsg.): The future of the climate. New insights, new challenges. A report from the Max Planck Society. Beck, Munich 2015, pp. 167-182, p. 178.

- ↑ Andre Sternberg, Andre Bardow: Life Cycle Assessment of Power-to-Gas: Syngas vs Methane . In: ACS Sustainable Chemistry & Engineering . tape 4 , no. 8 , 2016, p. 4156-4165 , doi : 10.1021 / acssuschemeng.6b00644 .

- ^ Brian Vad Mathiesen , Henrik Lund : Comparative analyzes of seven technologies to facilitate the integration of fluctuating renewable energy sources . In: IET Renewable Power Generation . tape 3 , no. 2 , 2009, p. 190–204 , doi : 10.1049 / iet-rpg: 20080049 .

- ↑ See also André Sternberg, André Bardow: Power-to-What? - Environmental assessment of energy storage systems . In: Energy and Environmental Science . tape 8 , 2015, p. 400 , doi : 10.1039 / c4ee03051f .

- ^ Weert Canzler , Andreas Knie : Smart networks. How the energy and transport turnaround succeeds. Munich 2013, p. 47.

- ↑ A. Moser, N. Red Ring, W. Wellßow, H. Pluntke: Additional needs to save earliest 2020. Electrical Engineering & Information Technology 130 (2013) 75-80, pp 77-79. doi: 10.1007 / s00502-013-0136-2

- ↑ See Volker Quaschning , Regenerative Energiesysteme. Technology - calculation - simulation . 9th updated edition. Munich 2015, p. 393.

- ↑ Martin Kleimaier: Using electricity instead of storing it . In: Energy 2.0 . No. 1 , 2013, p. 38–42 ( online as PDF, 1.38 MiB [accessed July 15, 2013]).

- ↑ Wolfram Münch, Malte Robra, Lukas Volkmann, Philipp Riegebauer, Dieter Oesterwind: Hybrid heat generators as a contribution to the system integration of renewable energies . In: Energy industry issues of the day . tape 62 , no. 5 , 2012, p. 44–48 ( available online [accessed July 15, 2013]). Available online ( memento of the original dated December 12, 2013 in the Internet Archive ) Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice.

- ↑ Shaping the electricity market of the future. Special report. In: umweltrat.de . November 25, 2013, accessed June 14, 2020.

- ↑ Günther Brauner: Energy systems: regenerative and decentralized. Strategies for the energy transition . Wiesbaden 2016, p. 89.

- ↑ Michael Sterner, Ingo Stadler: Energy storage - requirements, technologies, integration . Berlin - Heidelberg 2014, p. 424f.

- ↑ Michael Sterner , Ingo Stadler (Ed.): Energy storage. Need, technologies, integration. 2nd edition, Berlin - Heidelberg 2017, p. 457.

- ↑ a b Electricity-natural gas storage. Press release. In: iee.fraunhofer.de. April 26, 2010, accessed October 12, 2019 .

- ↑ Volker Quaschning: Renewable energies and climate protection . Munich 2013, p. 332.

- ↑ Michael Sterner, Ingo Stadler: Energy storage - requirements, technologies, integration . Berlin - Heidelberg 2014, p. 424.

- ^ Gregor Czisch : Storage Hydro Power in Europe. Rated Power, Storage Capacity and Annual Energy Production. Institute for Solar Energy Supply Technology (ISET), 2000, archived from the original on November 26, 2012 ; accessed on October 24, 2011 (English / German).

- ↑ Project map - Power to Gas. In: powertogas.info. German Energy Agency, accessed on October 15, 2019 .

- ↑ Florian Valentin, Hartwig von Bredow: Power-to-Gas: Legal framework for hydrogen and synthetic gas from renewable energies . In: Energy industry issues of the day . tape 61 , no. 12 , 2011, p. 99–105 ( energy-lawyers.com [PDF; 166 kB ; accessed on May 14, 2019]).

- ↑ Create incentives to make the electricity system more flexible. (No longer available online.) In: powertogas.info. German Energy Agency , archived from the original on October 2, 2018 ; accessed on March 13, 2019 . Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice.

- ↑ Glossary of regulatory framework. In: powertogas.info. German Energy Agency , archived from the original on July 1, 2015 ; accessed on March 13, 2019 .

- ↑ Michael Sterner, Mareike Jentsch, Tobias Trost, Amany von Oehsen, Lukas Emele: Motivation for energy storage and current developments in power-to-gas. (PDF; 4.7 MB) In: DBI-GUT Power-to-Gas 2nd conference. September 13, 2011, archived from the original on June 6, 2014 ; Retrieved November 28, 2012 .

- ↑ a b Volker Quaschning: Renewable energies and climate protection . Munich 2013, p. 329.

- ↑ Ariane Arndt: In Search of Saving. In: volksfreund.de . March 27, 2012, accessed October 19, 2019 .

- ↑ Michael Ziegler: Natural gas from green electricity: juwi and SolarFuel are testing methods for storing electricity. In: photovoltaik-guide.de. March 21, 2011, accessed April 9, 2020 .

- ↑ Uwe Krengel: Power-to-Gas also runs on small biogas plants - pilot test at the Hessian Biogas Research Center for direct methanation successfully completed. Press release. In: iwes.fraunhofer.de. Fraunhofer Institute for Wind Energy and Energy System Technology, January 16, 2013, archived from the original on January 21, 2013 ; Retrieved November 26, 2017 .

- ↑ The world's largest power-to-gas plant for methane production goes into operation: preliminary stage for industrial use achieved. In: zsw-bw.de. October 30, 2012, archived from the original on November 7, 2012 ; accessed on December 1, 2017 .

- ↑ Strong combination of wind and hydrogen. (No longer available online.) In: vdi-nachrichten.com . February 3, 2012, archived from the original on February 6, 2012 ; Retrieved February 3, 2012 .

- ↑ Greenpeace Energy delivers wind gas for the first time. Retrieved April 14, 2012 .

- ↑ Greenpeace Energy's gas customers are now also heating and cooking with hydrogen. In: greenpeace-energy.de . December 12, 2014, accessed March 15, 2020.

- ↑ Greenpeace Energy overturns plans for wind gas generation plant . In: EUWID New Energies . No. 48/2012 . EUWID European Economic Service GmbH, November 2012 ( full text ( memento of March 23, 2013 in the Internet Archive ) [accessed on June 29, 2020]).

- ↑ Energy.aktuell, No. 27 October 2013, p. 5.

- ↑ First wind hydrogen filling station opens in Berlin. In: wind-energie.de. April 19, 2012, archived from the original on May 15, 2012 ; accessed on February 6, 2020 .

- ↑ Operation of a fully integrated, public hydrogen filling station on Heidestrasse in Berlin (CEP). In: now-gmbh.de. Retrieved February 6, 2020 .

- ↑ Take: water, electricity and carbon dioxide. “Success story” of the Stuttgart Region Economic Development Corporation . (No longer available online.) In: wrs.region-stuttgart.de. February 14, 2012, archived from the original on November 3, 2013 ; accessed on June 9, 2020 .

- ↑ First industrial power-to-gas plant with 6 MW inaugurated ( memento of the original from April 7, 2016 in the Internet Archive ) Info: The archive link was automatically inserted and not yet checked. Please check the original and archive link according to the instructions and then remove this notice. , ETOGAS delivers the world's largest methane production plant to Audi AG, press release Werlte / Stuttgart, June 25, 2013, PDF 28 kB, 2 pages

- ↑ Audi e-gas - new fuel ( Memento from June 7, 2014 in the Internet Archive ), Audi

- ↑ DVGW Power-to-Gas Atlas 2013. (PDF; 60 kB) Accessed on January 29, 2014 .

- ↑ biopower2gas. Retrieved August 16, 2016 .

- ↑ dena: Falkenhagen pilot plant ( memento of the original dated November 1, 2013 in the Internet Archive ) Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice.

- ↑ E.ON puts the Falkenhagen pilot plant into operation. In: gwf-gas.de. August 28, 2013, accessed March 4, 2020 .

- ↑ BMU (Ed.): GreenTech made in Germany 3.0 - Environmental Technology Atlas for Germany . February 2012, p. 62; 263 ( vdma.org [PDF; 7.3 MB ; accessed on July 22, 2013]).

- ↑ The project RH 2 -WKA , accessed on November 2, 2013.

- ↑ The Thüga Group's power-to-gas system exceeds all expectations. In: wind industry. 2017, accessed November 29, 2018 .

- ↑ Facts about electricity to gas demonstration plant of the Thüga Group. (PDF; 4.5 MB) (No longer available online.) In: h2bz-hessen.de. Archived from the original on November 29, 2018 ; accessed on November 29, 2018 . Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice.

- ↑ The hydrogen showcase project is running successfully. In: energiepark-mainz.de. April 15, 2016, accessed June 16, 2020 .

- ↑ The world's largest plant: green hydrogen from Mainz started . In: IWR , July 8, 2015. Retrieved July 8, 2015.

- ↑ Mainz energy park . Retrieved June 15, 2013.

- ↑ Praise for the energy system in the business park. In: Allgemeine Zeitung (Mainz) , June 8, 2013. Retrieved June 15, 2013.