Fur ingredients

Fur ingredients , in Austria fur accessories , are the lining materials , inserts, closures and the like used in the manufacture of fur products . The collective term "fur ingredients" is not used in the singular, "a fur ingredient" (for example for a clip fastener , a piece of fur silk ).

The manufacture of fur ingredients takes up a fairly large part of the fur industry . Depending on the fashion, she has to turn to this article, then to another, to varying degrees.

history

In 1842, modern women's fur fashion began in London with a seal jacket , in which the hair was worn outwards. Until then, fur was mainly used for lining and trimming fabric clothing for men and women, at that time also especially for collars, capes, trimmings and the trimmings consisting of muff, scarf and hat. This era also saw the invention of the fur sewing machine , which made it possible to process and assemble fur much more cheaply. Until then, the fur itself was more of an ingredient in the fabric coat; apart from yarn, it hardly required any special auxiliary materials.

That changed with the fashion of fur trimmings. It consisted of the fur hat , a fur scarf, fur gloves and, necessarily, a fur muff . Not only the fur scarf was very often a fur animal modeled on nature, but also the muff and sometimes even the headgear were adorned with numerous tails with a so-called "plastered head". The tails were stuck in a trimmed bell, small cardboard shapes and glass eyes were needed for the heads, small claws made of sheet metal or celluloid for the paws, and more. In the fur ingredients trade there were ready-made, down-lined muff bags, then muff bags that are both muff and bag at the same time.

Above all, however, ingredients were now needed for fur jackets and coats. The leather side of the furs was pricked with linen binding fabrics to prevent tearing and with padding for warmth. Special, stable fur silks were fed in, for which two specialized silk weaving mills arose in Krefeld, the company G. Hollender Söhne (1842) and Peter Bircks & Cie. (1863). In the beginning, fur buttons that required a wooden shape as a core were usually used as closures. Many furs were closed with buttons and a concealed button placket. In 1934 the Arno Taschen company produced the first, initially exclusively decorative, clip fasteners, which were reduced to purely functional articles in 1952 and perfected by the Keskari company , which have been the characteristic fastening solution for furs worldwide since the 1950s.

Essential fur ingredients

Sewing material

When it comes to sewing material , a distinction must be made between thread , silk , thread and synthetic thread . The main colors are black, white and brown; the furrier needs colored yarns for the production of fabric clothing (covers for fur linings). In general, four-fold upper thread is used for hand seams (previously also for machine seams), the only double lower thread is mainly used for basting. For the fur sewing machine, instead of the straw hat weave , cotton yarns, as well as polyester and other synthetic fiber yarns are now used . Threads for hand sewing are sometimes still used for thick leather and sewing work that has to endure a lot.

Machine sewing silk, hand sewing silk and buttonhole silk are used. The strong buttonhole silk is used in all fur colors, it is used to make buttonholes and to warp the silk lining for coats and fur small items. The hand sewing silk is mainly used for feeding the silk lining and for other fine sewing work.

Fabric and non-woven ingredients

Lining silk, lining fabrics

Fur linings are, in particular, the silk-like fabrics made especially for lining fur clothing, more generally all silk-like fabrics used for this purpose. Most fur garments that are worn with the hair facing outwards are lined with silk. It should cover the fur leather with its seams and darts as well as the inlays, increase the sliding ability when putting on and taking off, improve the fall of the garment and give it a good interior appearance.

For relining of fur covers one takes cloth or felt earlier for simpler fur blankets and jute and burlap. Lining silks are used less for this, they are not as warm and undesirably slippery.

Stapling / pricking materials

In order to give the fur objects greater durability , the leather side can be provided with a binding or pricking material . To a finish provided Pikierstoffen include Jaconet and shirting . Pricking fabrics that have not been finished are much softer, but they warp more easily.

Most of the stapling, pricking and interleaving materials are also available as fixing material, which can be ironed on with an iron, but above all with a fixing press.

Ribbon tape is used to secure the fur edges against shape-changing stretching and tearing of the fur ( main article: → ribbon tape ).

Interlayers

Between the silk lining and the fur leather, if pricked over the pricking fabric, intermediate layers can be worked into the fur to make the fur warmer and softer. Was formerly exclusively Wadding (a wool wadding) or Swaneboy (a Barchentstoff , also known as flannel ) is used, is trading for today different, very light synthetic fleece and foam materials available (for example Thinsulate ® ).

Stiff linen , a heavily finished half or pure linen , is used to keep the shape, especially the collar and the front edges in jackets and coats . For stiffeners that are to be particularly resilient and durable, for example for Stuartkragen and the reverse is horsehair used. Less stiff nonwovens (for example Vlieseline ® ) fulfill the same, but not as permanently elastic, function .

Closures and fittings

The usual means of fastening for fur clothing has been a small clip fastener consisting of a hook and eye since the 1950s. Both are sewn from the leather side in such a way that they are barely visible on the hair side of the furs. Even more inconspicuous, simple hooks and eyes are used as the top closure on the lapel corner and on the collar corners. In the past they were crocheted in the better version, today they are more durable with a wound wire.

Depending on the respective fashion, buttons are also used, which are then often blindly put on as pure decoration, since buttonholes in fur due to hair abrasion are a significant cause of repair. The buttons are usually larger and more elaborately designed than in the textile industry. Until the end of the 20th century, such buttons were still used to a considerable extent as a design element, often in double rows. The same button was mostly used in a smaller version for back belts, cuffs and cuffs. A wide underlap can be held with a button flap, and especially flat inner buttons are used for closing. Fabric coats and jackets for the fur lining are usually given simple buttons, similar to those used in the textile industry, they can be provided with the company logo.

In 1937 it was said: “Today's buttons, especially for women's fashion, are quite large and, in addition to the well-known round shape, also have angular, elongated etc. The material is very different. For skinning, leather buttons and buttons covered with fur are mainly used. ”At the time, a“ trial button ”was also available for customer fitting, which was temporarily attached by simply piercing the leather and which saved the difficult plugging of the fur in the case of thick leather. There was also a "button protector" into which the artful and sometimes delicate buttons could be clicked so that they would not be damaged when the fur was knocked out .

The once common fur buttons, in which the fur is pulled over a button shape made of wood or pressed cardboard, are only occasionally used for design purposes. The button inlets were supplied with or without an eyelet. As a base there was a disc made of aluminum or vulcanized fiber , to which the ends of the tape, which were pulled through the fur and attached to the button, were knotted instead of being sewn to the leather. In addition to pure leather buttons, basic shapes are available for leather-covered buttons, consisting of a head and a base plate. At least in larger fur-processing companies, these buttons are punched with a punch in the studio instead of in a pleated fabric.

In addition, different, simple function buttons that are not visible to the outside are required, such as interior fastening buttons or particularly small and flat buttons for removable inner lining. Snap fasteners, zippers and Velcro straps are also among the fasteners required in the fur industry.

" Keska " clip fastener

Muff ingredients

Special ingredients are needed for the socket . A distinction is made between barrel muff, pocket muff and sleeve pocket. A suitable down or synthetic bag, which is usually prefabricated, is required for all of them. The usual hand warmer pockets with a warming hand space are, as opposed to the Muff, real handbags. They are offered according to the respective bag fashion. The only remaining German manufacturer for the item, which is currently less in demand, is probably the Keskari company . As of 2018 Muff bags and pouches are delivered ready-made and the furrier fills the areas provided with fur, the type of fur to match his collection or according to customer requirements. A small pocket is usually incorporated into the simple barrel muff bag.

Collar Ingredients

At the end of the 19th and beginning of the 20th century, a very big fashion theme, the fur necklace, no longer plays a role in fashion at all. The ingredients used for this were varied: cardboard or wooden shapes for the heads in different sizes, glass eyes in different designs and sizes, artificial claws made of sheet metal or celluloid for the various types of animals, artificial noses made of leather or rubber or nasal putty and rubber for self-modeling, trimmings chains and crocheted ball printers and collier clips .

Until the 1940s, the fur ingredient shops also carried the head shapes for predators used by taxidermists in all sizes. Not only animal preparations, but also so-called fur rugs usually had a head. Furriers, who dared to do this, modeled the heads of the rugs they offered themselves.

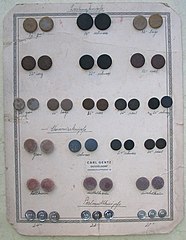

- Collar Ingredients Sample Cards, circa 1950s or earlier

Fur ingredient trades

The fur ingredients trade via the actual fur ingredients addition, the tools used in the fur production, such as skinning knife , purpose pliers and needles , chemical products, such as leather fat and hair color, as well as others required in the furrier workshops and fur shops articles and by-products.

Web links

Individual evidence

- ↑ a b Alexander Tuma: Pelz-Lexikon. Fur and Rauhwarenkunde, Volume XX . Alexander Tuma, Vienna 1950, p. 162–163, keyword “fur deeds” .

- ↑ The new clip fastener . In: Der Rauchwarenmarkt No. 26/27, Leipzig, April 7, 1934, p. 9.

- ↑ a b c d e Without details of the author: Ingredients for fur processing . In: Die Kürschnerfibel No. 2, supplement to the Kürschner-Zeitung No. 6, Verlag Alexander Duncker, Leipzig, February 21, 1938, pp. 13-20.

- ↑ a b c d e f Friedrich Lorenz: Rauchwarenkunde . 4th edition. People and Knowledge, Berlin 1958, p. 207-212 .

- ↑ Without author's name: Fashionable ABC . In: Die Kürschnerfibel No. 9, supplement to the Kürschner-Zeitung No. 27, Verlag Alexander Duncker, Leipzig September 21, 1937, p. 103.

- ↑ a b Without indication of the author: Ingredients for fur processing . In: Die Kürschnerfibel No. 4, supplement to the Kürschner-Zeitung No. 12, Verlag Alexander Duncker, Leipzig, April 21, 1938, pp. 40, 42.

- ↑ Undated Catalog no. 43 (not before 1925; 1930?) From home Ding & Bergmann, Pirna / Sachsen, p. 9

- ↑ Without information about the author: Ingredients for fur processing . In: Die Kürschnerfibel No. 3, supplement to the Kürschner-Zeitung No. 9, Verlag Alexander Duncker, Leipzig, March 21, 1938, pp. 25–32.