Skinning knife

A skinning knife is a hand tool used to cut fur. It is very different from the shape of other cutting tools. Originally made from the best steel, today it also describes a corresponding blade holder with exchangeable blades.

history

As the term skinning knife suggests, the actual development of a special knife for cutting skins (previously also known as a cutting knife) begins with the emergence of a separate branch of the fur production, that of the furrier . Previously, the making of fur clothing or clothing adorned with fur was usually the responsibility of the women whose husbands brought home the fur animals they had killed. Near the village of Swanscombe in the county of Kent ( Borough of Dartford ) in England , among many other finds, a stone-made hand tool for working leather from the Acheuléen culture of the Paleolithic age that looks amazingly similar to a modern skinning knife was found. It can also be said that the Iron Age skinning knife differs less in shape and size than in a more suitable material from the flint knife of prehistoric people. Until recently, Eskimo women use a special, semicircular knife, the ulu, to remove the flesh and cut the skins . A knife very similar to the Ulu was in use by the furriers of Asia until the end of the 20th century. For the Eskimos, however, it was an all-purpose knife that was used for all incidental cutting work, but mainly for fur processing, for which it is also specially shaped.

In the 14th and 15th centuries, skinning knives still had the shape of an ordinary, strong bread knife. In the 18th century they had a short handle. If you follow OL Hartwig, it was not cut with the tip of the blade, as it is today, but with the entire cutting edge. The present-day, particularly hand-made form of the skinning knife was created around 1800.

In the 1890s, King Camp Gillette invented the disposable razor blade. The skinning knife with an exchangeable blade was probably not used for the first time until the 1930s. The inevitable transition from all-steel knives to blade knives became apparent when the manufacturer Alexander Kemper , based in Messhaus Leipzig since 1884, advertised: “New: Swedish steel knife, thin as a razor blade”. But even in 1941 German furriers were still advised to use the all-steel skinning knife when cutting, even if it cannot be denied “that some types of fur, especially when they are old, can hardly be cut with the sharpest skinning knife. This is mainly the case with some species of lamb. In such cases the razor blade does a really good job ”. The 1950 fur lexicon confirmed that the blade knife found "a less favorable reception". However, it must be taken into account that the introduction of the new knife with the still quite expensive blades took place during the Second World War and the subsequent emergency. - Usually the skinning knife was one of the tools that the apprentice furrier himself had to provide. When the blade knives came into use, the journeymen in many companies had to pay for the blades out of their own pockets for a long time.

Modern Eskimo knife

(steel, caribou horn)

Condition (shape, material)

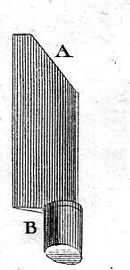

The knife, which was common in modern skinning before the advent of the blade holder, is made from top quality sheet steel. The shape is adapted to the use and the hand. The curved back and the narrow spout, which is usually provided with a brass extension, are particularly striking. An exquisitely pointed tip is essential for use in order to be able to pierce the fur leather. The all-steel knives were available in different degrees of hardness. It was recommended not to choose a knife that is too hard or too soft. When working with hard steel, nicks easily jump out or the point breaks off; the knife that is too soft will quickly become blunt again.

The modern European all-steel skinning knife has a shape adapted to the shape of the hand, early shapes were somewhat larger and clumsier. With the refinement of the working techniques, the tools had to be further developed accordingly. The rear narrowed approach is used to mark the leather. The size of the all-steel skinning knife is different and depends on the size of the hand, as well as on the habit of the worker. Experienced furriers had their knife sharpened in such a way that the point was not only sharp towards the edge, but also slightly up the back of the knife. This enabled the cut to be made both towards and away from you without turning the knife. However, it is not recommended for beginners.

The blade holder, which is only used almost everywhere today, corresponds in shape to the all-steel skinning knife. However, it is not produced in different sizes, but the models vary somewhat in shape and size depending on the manufacturer. In the beginning, various skinning knives with special blades were offered, but in Europe it is predominantly models that use standard razor blades. Commonly used in specialist companies are blades that are specially made for skinning knives by a Solingen company, somewhat thicker and cheaper blades, which can also be easily broken without being bent. The blade is divided in length before it is clamped in the holder or, depending on the model, screwed in. The special furrier blades are also available pre-broken. Half of the blade is also broken off at the end before being inserted into the blade holder, pointed to the cutting edge.

The skinning knife most recently used in Germany and originally protected by a utility model corresponds to that of the Sievers company ("Sievers System"). It is made of brass; the blades are easily held with a simple clamping device. Below is an aid for breaking the blades with a marking of the breaking angle. The Sievers company no longer exists, but the knife is still produced in almost the same design.

- Various all-steel skinning knives and blade holders

Cutting the skins

All-steel knives need to be sharpened on the damp whetstone from time to time. A particularly fine point is obtained by grinding the cutting edge upwards in an arc shape. In between, the cutting edge is pulled off the worktop or, better still, a leather strap like the one used by barbers in the past ; that is, the fine nicks that arise during cutting are smoothed out. Experienced furriers kept several knives in stock so that they did not have to stop working if a knife became blunt. In addition to the sharpened knives, the specialized American fur cutters (cutter, cut = "cutting") also had more angular specimens ready for certain jobs. The cutter was at the top of the hierarchy of the American fur workers, his job was between that of the sorter and that of the sewer, the tensioning (“ purposes ”) of the sewn fur was already the job of another specialist, the purpose . When the blade knife has become blunt, a new blade is inserted or the blade is turned; When cutting a mink skin to leave it out, this can be necessary after about every skin or even more often, depending on the type of leather and the quality of the blade.

One of the first jobs in the fur production is the opening , Austrian bribery, the removal of the damaged areas of the fur.

The Austrian master furrier Alexander Tuma describes the proper use of the furrier knife as follows:

“The knife has to be easy to hold. Those who do the same badly will not make a good cut. [...] We take the knife in hand so that the cutting edge is pointing downwards. The point points forward; the raised back rests firmly in the ball of the hand. On the left is the thumb on the knife, on the right the curved middle finger. Run your index finger over the back of the knife to near the tip. The hand is supported by the little finger resting on the fur to be cut. The whole hand goes along with the incision; the index finger resting on top of the knife edge presses on the knife depending on the thickness of the skin on the resulting resistance. While the right hand guides the knife, the left holds the skin.

If the cut is made from the edge of the fur, then the knife starts about in the front quarter of the cutting edge, but if it is cut in the middle of the fur, the tip of the knife must first penetrate the fur. Then the cutting edge moves up to about half of its length, is then pulled out of the cut, if it is not yet over, reattached and cut further.With a short cut, the hand can rest more firmly on the skin, but the more it is The cut increases in length, the more flexible the hand has to be in order to be able to follow the cut. "

Cutting can be done in three different ways:

- 1. For right-handed people, the thumb is on the left side of the knife, the index finger on the curved back of the knife, while the middle finger is on the right of the knife. These three fingers hold the knife. The ring finger and the little finger are slightly curved on the skin part and provide guidance. The left hand keeps the fur smooth when cutting. In particular, short and curved cuts are made in this way.

- 2. The back of the knife lies between your thumb and forefinger. The thumb, coming from below, lies on the left side of the knife, while the two front links of the index finger lie on the curve of the back of the knife and exert the pressure when cutting. The middle and ring fingers are curved on the right side of the knife, while the little finger is stretched out on the skin part and provides support and guidance. The handling is very similar to the first type, only the knife is grasped from behind and the hand does not grasp from above, but from below. Usually the second type is used when long and straight cuts are to be made.

- 3. The knife is rotated so that the blade points upwards. The hollowed back part of the knife's back lies between the thumb and index finger, the thumb on the left and the index finger on the right of the knife. The other three fingers are curled up behind the knife, with the little finger providing guidance if necessary. The direction of cutting is not towards the body as with the previous knife positions, but away from the body. This type of cut is used when cutting the fur from the hair side and at the beginning of cuts to get a safe approach for one of the first two types of cut.

The fur never lies flat on the surface when it is cut, but is lifted slightly with the free hand, otherwise hair would be cut off with it. Therefore, cutting with scissors is also prohibited. This is another reason why you always cut with the hairline and not against the direction of the hair. The blade should therefore hardly penetrate deeper than the leather thickness, the cutting depth should be kept as small as possible. Half the blade can then be turned over and used again by breaking a second point on the opposite side, which is still sharp.

Edging of a galonized silver fox fur

Cutting outlet cuts

Hide cutters

- Special dispensing devices and machines have been developed for leaving out the skin, producing the desired skin shape and appearance by lengthening the skin at the expense of the width, in which the skin is broken up into strips up to 3½ millimeters.

- Special tools and cutting devices have also been available since the second half of the 20th century for air gallooning , in which the skin is scratched with about 1.5 centimeters long, staggered cuts in order to then stretch it out over a large area in a grid.

- In 1928 a furrier handbook pointed out to those furriers who used the waste as special work that a punching device had now been invented that quickly and evenly took care of the time-consuming cutting of the small pieces of fur. These punches, like the whole device, work in such a way that the hair is not cut off. The punches are interchangeable for the individual shapes and enable quick and meticulous work. In the past, special punches were made for industry for cutting the serrated or wavy connecting seams that are common with curly skins ( e.g. Persian , Indian lamb ). In industrial production, punches are also used in particular for cutting small pieces of lambskin , for example for slippers and gloves.

Web links

See also

supporting documents

- ^ Books.google.de: Michael Brandt: Brain and Language: Fossil Testimonies to the Origin of Man . P. 74. Last accessed January 18, 2016.

- ↑ Paul Larisch : The furriers and their characters . Self-published, Berlin 1928, p. 164

- ↑ Paul Larisch , Josef Schmid: The furrier craft . Part II, self-published, Paris without year (1902), p. 30.

- ^ PN Sprengel's arts and crafts in tables . 2nd collection, 2nd edition, Verlag der Buchhandlung der Realschule, Berlin 1782, p. 432.

- ^ Membership directory of the Reichsbund der deutschen Kürschner e. V. 1928 . Verlag Arthur Heber & Co., Leipzig, p. 132.

- ↑ a b Without mentioning the author: apprenticeship training. The handling of the tools . In: Die Kürschnerfibel , No. 11/12, supplement to the Kürschner-Zeitung No. 35/36, Leipzig December 15, 1941, pp. 50–53.

- ↑ a b Alexander Tuma: Pelz-Lexikon. Fur and Rough Goods, Volume XIX . Alexander Tuma, Vienna 1950, p. 103, keyword “skinning knife” .

- ↑ a b c d Alexander Tuma jun .: The furrier's practice . Julius Springer, Vienna 1928, p. 32-34 .

- ^ Cyril J. Rosenberg: Furs & Furriery . Sir Isaac Pitman & Sons, London 1927, p. 49 (English).

- ^ David G. Kaplan: World of Furs . Fairchield Publications. Inc., New York 1974, pp. 72-73 (English).

- ↑ Alexander Tuma jun .: The furrier's practice . Published by Julius Springer, Vienna 1928, p. 237