Furrier

A furrier (out of date also Buntfutterer , Pelzer , Wildwerker , Grauwerker etc.) is a craftsman who processes animal skins into fur clothing and other fur products.

history

Even in the younger Stone Age , fur was an important warming and decorative element of clothing, contrary to previous ideas, according to Josef Winiger (1995), in combination with textiles made of fibers, bast and wool. Even the oldest surviving fur clothing, that of the man from Tisenjoch, Ötzi, shows advanced elements and techniques that are still used today. Ötzi wore a jacket that combined light and dark fur strips that were worn on the outside, leg warmers made of pieces of fur using the overcasting technique, and a material mix of bear leather soles and deer fur upper material and a supportive and insulating inner shoe made of plant material and fabric for the shoes.

The word kursina (fur skirt) has been used in Old High German and Old Saxon since the 9th century . The trade names Kürsner and Kursener are derived from this . In Northern Germany, the fur craftsman's profession was divided into furriers and pelters. While the furriers processed the more noble types of fur into fur linings , trimmings and trimmings, at first only the furs made the cheaper lamb and goat skin pelts, which were usually worn with the leather side facing outwards. In the area of the northern German united Wendish seaside towns and southern Lower Saxony , a distinction was also made between “approaching” and “darting”, the upper states and the Dutch. The Seestädter or Dutch people sewed towards themselves from above or stabbed inwards and were called closer. The Oberlanders, also called Landstädter, sewed away from themselves, from bottom to top, they were called darts or darts. If one of the journeymen moved to the area of those who sew differently, it could well be that the masters there were forbidden by their guild to employ him.

As one of the first trades, the furriers formed guilds . The oldest known statutes come from the Rouen area (France) from around 1160. Further guilds were founded in 1226 in Basel , 1272 in Vienna , 1273 in Breslau , 1277 in Braunschweig and 1280 in Berlin . Joint guilds were often founded with other trades, for example in Braunschweig with the white tanners and the glove makers or in Basel with the tailors .

The furrier trade was widespread. The Augsburg guild (founded in 1368) had 86 masters by 1475 and 107 masters by 1536. In 1555 there were 45 masters in Leipzig , and in 1499 there were 92 masters in Breslau. With the introduction of new valuable fabrics at the end of the 16th century, the furrier trade initially lost its importance.

Skinning is a seasonal trade . From October to December the greatest income is generated. That is why the warm months were used to dress ( tan ) the skins. As a service, fur goods were sulphurized and aired in the summer months in order to give the clothing the highest possible durability and resistance to pest infestation.

In the 18th century, the trade fairs in Leipzig (Brühl), Frankfurt am Main and Braunschweig were the main markets for the German tobacco trade. Breslau and Groß-Glogau were centers for tobacco products from Russia , Poland and Bohemia .

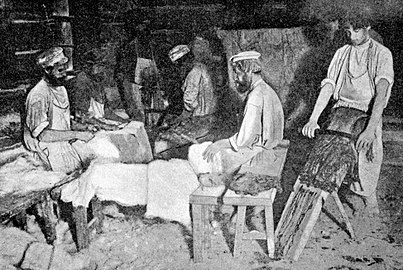

Already in the early modern period a division of labor developed in which pieceworkers and table masters were employed. Until the later division of production, the furrier still tanned his skins himself. For this he was dependent on running water; the saying swim the skins away from someone still bears witness to it. Dealing with the skins of dead animals meant that skinning was counted among the unclean crafts. Due to the strong odor and also some noise (when knocking the furs ), the furriers were often forced to settle down on the rivers on the edge of the cities. Occasionally the skins had to be prepared in a guild administered yard . However, in contrast to the red and white tanners in Leipzig, for example, the furriers were allowed to do their work within the city walls. They were only instructed to carry their stain to a flowing body of water so that no big stink was made in the city .

Despite the impurity of their craft, furriers were among the most respected and advisable craftsmen in Europe. In Asia, on the other hand, due to Buddhist, Hindu and Shinto ideas and guidelines, employees in meat, leather and fur processing were subject to special reservations. Most furriers bought skins directly from hunters and farmers in order to deliver the processed furs directly to the end consumer after processing . There were conflicts with white tanners, bag makers , glove makers and parchment makers , as there was often only a limited amount of hides and skins to process.

Most of the work with the needle was paid for on a weekly basis; From around the middle of the 19th century, the two main processes separated completely, there were now the bank fritters (dressers) and the needle fryers. The (needle) furriers soon specialized again in semi-finished product manufacturers and the furriers for finished fur clothing, wholesale or detail. Originally almost exclusively male journeymen worked in the small workshops alongside the master's wife.

With the introduction of the fur sewing machine and the increase in fur heels made possible by it, from around 1880 more and more fur seamstresses initially only did the sewing work of the furriers. Before 1931, Fräulein Rohlik was the first woman to take the master furrier examination in Berlin. At that time, as a trade journal writes, there were 'at least' ten female furriers. Since around the 1970s, the gender ratio in the journeyman's exams has been more or less balanced.

Records of working techniques have been handed down since the 18th century, and there were probably no complex changes in the shape of the processed skins, as can be seen in numerous old pictures, up until this time. The drawing of patterns was still a rarity among furriers at the end of the 19th century, and people mocked each other downwards in the ranking as “academically educated”, “sable barons” and “rabbit butcher”. The development of the furrier trade took off rapidly with the invention of the fur sewing machine by Joseph Priesner around 1872 (also available with a small motor since 1888) and the employment of female workers. Soon there was a shortage of skilled workers in France, England, Switzerland, Italy, Belgium, Holland, but also in North America, to meet the great demand. Although there was a long-established, modern fur industry there, they were forced to recruit foreign furrier journeyman. At that time only Central and Eastern Europe were considered, especially Germany, Scandinavia, Austria-Hungary and the Balkans. A move to the west that was unique in the industry began. Thousands took this route that led to North America. The migration began around 1874, peaked around 1900, and then subsided again by the First World War . In 1929 a Hungarian furrier and tobacco merchant stated: Whether in Tientsin , whether in London, or even in Paris, you can communicate in German everywhere in our branch.

After 1850 the area around the street Brühl in Leipzig was a center of the European tobacco trade. Numerous tobacco shops were built in and around Leipzig. By 1914, Leipzig grew into the most important trade fair for smoked and fur products from all over the world. During the First World War , the city initially lost its importance as a center of the international tobacco trade, but was able to partially regain it from around 1922 with the opening of a large tobacco shop in the Soviet Union. In 1928 the most important furrier school of the time was opened in Leipzig .

GDR

In 1945, after the end of the Second World War , there was a divided development of the furrier trade in Germany. In the Soviet occupation zone , too, the demand for furs grew despite difficult material procurement; Mainly skins from small animal breeding were processed. As long as the owners were still alive, the furrier businesses that had been shut down during the war continued to run; only rarely were new companies founded. With the founding of the GDR , the allocation of materials was controlled by the state and, since 1949, the furriers were forced to form purchasing and delivery cooperatives (ELG) . The furriers were usually more than busy; the customers often had to accept long waiting times, i. In other words, there was a typical provider market.

The efforts made from the mid-1950s to group the furriers in production cooperatives of the craft (PGH) were not very successful. The state pressure on the companies alternated constantly between PGH and private company. In the spring of 1982, 41 companies in the tobacco industry were named as state-owned companies for ten years. Craft businesses with up to ten employees plus apprentices were better off than the rest of the commercial economy. Despite all the difficulties, the furrier companies in the GDR were financially sound.

The furrier craft businesses formed professional groups comparable to the guilds, at the head of which there was still a head master. You were a member of the state-controlled chambers of crafts. As in the Federal Republic of Germany, apprentices were trained in the factories; the initially local vocational school training followed later as block lessons in Leipzig. The master craftsman's examinations were also held within the craft; Every two years the journeymen were prepared by master craftsmen. The specialist magazine "Brühl" and some qualified specialist books support the training and further education of employees and company owners. Regional and supraregional specialist conferences on further training and collegial cohesion were held regularly. Since 1964 there has been a performance competition taking place at different locations . The winning models have been participating in the international fur model competition of the Council for Mutual Economic Aid (RGW) since 1971 . This resulted in contacts with specialist colleagues from Moscow to Ulaanbaatar and Zakopane .

Although the larger state-owned companies also produced for West German corporations, the level of manufacture remained essentially at the pre-war level.

After the fall of the Wall in 1989, a completely new situation arose for the furrier trade in the former GDR. The initially high expectations were not fulfilled; on the contrary, the original 420 establishments were reduced to around 65 in 2000. The desires of consumers initially turned to other, previously non-existent offers.

Federal Republic

In the Federal Republic of Germany , handicrafts continued to develop after the war, as the demand for furs rose steadily. Fur farming, which began at the end of the 19th century, continued to grow with the rapidly increasing demand. Fur farms have been criticized and attacked since around 1980, and protests by animal rights activists tightened regulations and laws in Germany and Europe. Nonetheless, unsustainable conditions in fur farms have repeatedly been reported.

Changed consumer habits such as the triumphant advance of leisure fashion even on festive occasions, considerable market saturation after mass production in the second half of the 20th century, the focus on mink fur as a status symbol, the competitive pressure of low-wage countries and, last but not least, a series of very warm winters led to one significant reduction in furrier businesses.

Austria

At least until the end of the 20th century, Vienna was considered to be a leader and example of particularly elegant and opulent women's fur fashion.

The review of a Berlin fur magazine about "Viennese chic" from 1925 was initiated:

- “In recent years, Viennese fur clothing has made it worthy of imitation to achieve something very special in the production of good models, even though it obtains most of its raw material from Leipzig. But the safe attitude for fashionable things from Viennese clothing in the hands of capable furriers, who are mainly recruited from the formerly Bohemian population, give these fur processing a very special and elegant cachet. "

Elsewhere in the same issue of the magazine, the head of the Viennese furrier cooperative Johann Ily was quoted as stating that Viennese fur fashion was only regularly created in Vienna "when it saw the light of day in Paris". The author of the article stated: "The Parisian furrier consciously creates for the whole world, the Viennese only for the Viennese woman". In conclusion, however, he stated that the more timeless Viennese furrier's piece, which is also suitable for older women, is popular all over the world.

Job profile today

In addition to the production , repair and care of furs, customer advice, model design and material selection are among the tasks of the furrier.

Skinning has been a non-licensed craft in Germany since 2004 . Thus, journeymen can also run their own business without having many years of professional experience or a master craftsman 's certificate. Furrier is a recognized profession. The training usually lasts three years and includes not only manual skills but also the imparting of commercial knowledge.

After the rather classic fur in the past few decades, design and fashionable style have become more and more important for the furrier profession. However, the area of responsibility of the furrier still includes the complete production of a fur, design and pattern production, sorting, cutting and sewing of the fur, the purpose (smooth clamping), leveling, stapling, sewing together, finishing and feeding of the fur part. In addition, there is the sewing of fabric covers for fur linings , the processing of leather and fabric in connection with fur processing and the production of small furs such as scarves, muffs or simple hat shapes. A significant part of his work in the summer months consists of caring for the customer's fur : fur remodeling , repairs, fur cleaning , fur storage ( preservation ) and other service work.

Depending on the size of the craft business, after the end of the apprenticeship there is often a specialization of the activity in the tailoring and the sewing skinner, i.e. all sewing work is carried out by the fur seamstress (up to around 1960, at least regionally, also known as skinning maid). For sewing with the fur sewing machine, there is often a renewed division of labor, in particular also for sewing the so-called outlet work (lengthening the skins using cutting systems). - In addition to his normal furrier work, the master usually manages the workshop, talks to customers, creates the patterns and does the fittings. If he is not, as is usually the case, the owner of the business at the same time, the activities overlap, especially in purchasing the goods, developing models, calculating and selling in the shop. Every year he has the opportunity to take part in the international design competition of the German furrier trade.

The purchase of goods for skins and clothing is carried out via wholesalers and at the Mifur tobacco trade fair in Milan , for skins at international auctions, either directly from the owner and / or the master or via commission agents .

The training takes place in the companies of the furrier trade. The school part of the training usually takes place in block lessons at the vocational school in Fürth (Bavaria), the preparation for the further possible completion of the master’s examination is often done at the Frankfurt School for Clothing and Fashion .

The furrier's tools

- Skinning knife

- The skinning knife was originally a sharpened piece of steel that was sharpened to a point on the moistened whetstone if necessary. Today the term describes a blade holder in roughly the same form.

- Purpose pliers

- Pliers for gripping the fur edges and nailing the fur with purpose nails or pins for purposes (smooth clamping).

- Purpose pistol, hand tacker

- Tools for nailing on (compressed air or occasionally electric tacker, first launched in 1964, or by spring pressure).

- Purpose plate, purpose table

- the moistened parts of the fur are then nailed on to make them smooth; often heatable and with fans.

- Tap

- for pulling out the purpose nails or the purpose clips .

- Seam roller, rolling wood, expanded wood

- for smoothing the seams and soft rubbing of the fur.

- Brass comb, wire brush

- for hair treatment.

- Copy wheel

- for marking features of the hair side on the leather side and for creating patterns.

- Grotzenstecher , Stechle

- at least in name to mark the groan (the middle of the fur) on the leather side.

- Yellow pencil (grease pencil) and chalk wheel

- for markings, inscriptions and other identification on the skin side; also the powder bag for the simplified drawing of fur templates (zigzag or wave patterns for fur connections).

- Brush tweezers

- for coating the hair when sewing with the fur sewing machine.

- Muff blocks, hat blocks

- for clamping various muff or hat shapes; Head shapes for making necklaces (animal-shaped scarves).

- Scissors, Evel scissors, pins and needles, sewing ring, iron, tape measure, folding rule.

As a furrier needle, a real triangular needle, a sewing needle is commercially available that is almost no longer used in skinning. Before the invention of the fur sewing machine, it was used to sew particularly thick skins, for example very strong sheepskins for sleigh or coach skins . Since the triangular needle does not stretch the fur, but rather cuts it, it does not create a tear-resistant seam.

The furrier's machines

- Fur sewing machine, single thread blind stitch sewing machine for joining the skin parts with an overcast seam.

- The beginnings of this sewing machine with overlock stitches go back to around 1800. Balthasar Krems from Mayen in the Eifel is responsible for the basic construction of this machine, which has remained the same in its essential features to this day. Around 1870, the Rittershausen company in Berlin built the first overlock machines in large series. From 1888 they were increasingly equipped with small electric motors.

- Pricking machine, single thread blind stitch flat sewing machine for applying intermediate ingredients such as pricking fabrics, nonwovens or wadding

- Trouser press instead of the iron-Pikierens of intermediates to the fur leather side

- Sewing machine for sewing the inner lining and for tailoring work

- Leather quilting machine

- Tapping machine for removing dust, loose hair and cleaning flour after lautering in the

- Lauter barrel, for cleaning with wood flour and soft shaking of fur.

- Steam steamer to inflate hair.

- Ironing machine for straightening hair, especially for furs with a velvet look.

- Outlet cutting machine, cuts the fur into narrow strips. Slightly shifted, these are sewn together to form strips the length of the fur part (for example, the length of the coat)

- Outlet machine, a construction by Pfaff , which managed the entire process of cutting into outlet strips, moving the strips and sewing them back together in one automated operation. Because of the high price it was only built in small numbers (from 1983).

- Fur edge trimming device, an additional device for the fur sewing machine. It was also presented by Pfaff at around the same time as the outlet cutting machine. It was used to automatically cut off the skins that were left out when sewing the left out strips together, usually a time-consuming and unpleasant manual work. However, it does not appear to be known whether the device actually went into series production.

- Easier machine , for sewing in the fabric lining, is occasionally used in the manufacture.

Technical terms of skinning

- Matching : The cutting of the stretched fur part

- Opening : The repair of the damaged areas in the fur

- Leaving out : Lengthening the skins at the expense of the width by means of V or A-shaped cuts (opposite: let in )

- blue : color name for the darkest, bluish winter coats, contrast red

- Bleaching : The lightening of dark colors, often in order to then dye the skins in a different color. Also for the additional lightening of already white skins, usually combined with treatment with optical brighteners. As part of a model redesign u. U. also possible with yellowed, worn fur parts

- Blending : Darkening of the upper hair by only lightly spreading the color, also for darkening the fur leather. The latter serves to prevent the white leather from showing through on the hair side (leather covers;the term " nigrosine ",which is mostly and universally used inskinning, is alcohol-soluble, aniline black, actually dark blue ).

- Body : Rectangular fur (pieces) prepared for processing a piece of fur, usually made from small fur or leftovers by specialty companies

- Eulanizing : General term for making clothing or carpets insect- proof , originally using the chemical chlorophenylide (brand name Eulan ) from Bayer AG

- Dyeing : Frequently used finishing technique , especially to achieve current fashion colors. As part of a model redesign, this is often also possible with worn furs. Without prior bleaching, the fur can usually only be colored darker than before; the color options are limited by the resulting mixed colors. A previous bleaching process that is possible with new material may no longer be able to withstand old furs in connection with dyeing .

- Feathers : The intermediate sewing of narrow leather strips (generic term → Galonieren ) in V-shape, often combined with → omitting

- Female : The female small fur animal, especially in the mink (also: fah)

- Finish : The final treatment of finished furs e.g. B. by brushing and roughening the hair, by → knocking, → lautering, shaking soft, steaming the hair with hot air guns, ironing the hair with special fur ironing machines. Some of these processes can also be used to freshen up and care for worn furs. Execution by the furrier or by passing on to specialist companies

- Galonizing : The intermediate sewing of leather strips or textile ribbons is mainly used to enlarge the fur surface. Air gallooning: In long-haired, thickly haired skins, the leather is cut at short intervals and fixed in a grid-like manner. The result is a particularly fragrant, softly falling product with a simultaneous increase in area.

- Braided, knitted furs : Furs are cut into, usually the narrowest possible, strips and woven as threads into textile shell nets, usually by winding the fur threads around the netting threads. Since the result is a product with hair on both sides, this working technique is particularly suitable for small items such as scarves and stoles, but also for jackets (cardigan look) and coats. Because of the large amount of work, mostly from low-wage countries (China). The hand-woven fur from a German manufacturer was first mentioned in 1962 as a pram lambskin set made from Australian lambskin.

- Awn : For skins with upper hair and undercoat, the upper hair (e.g. all species of marten such as mink, otter, sable etc., lamb and kid have no undercoat, for example)

- Grunt : The back of the fur (usually the longest, often darker)

- Cover : The overcoat for a fur lining

- Kahlauer : A hairless area in the fur

- Knocking : The removal of loose dirt and any insect larvae by knocking out by hand with cane or hazelnut sticks or with a fur knocking machine. One of the basic tasks of the furrier in the context of fur preservation

- Preservation : Summer fur storage with simultaneous care by a fur specialist

- Lautering : The cleaning of the furs with wood flour

- Leather-ready : The condition of the cut fur part before the interior processing is applied

- Male : The male small fur animal, especially in the mink (also: male )

- Mutation colors: New coat colors created by sudden, erratic, natural, inheritable color changes (especially with mink, nutria)

- Nourkulemi : specially processed throat pieces , especially for mink and sable

- Naked fur : Old, rarely used term for coats or jackets made of lamb or goat skin , also " as if grown ",to be worn with the leather side facing outwards. Often embroidered (costume fur)

- Pricking : The sewing of textile intermediate materials (between fur and inner lining) onto the leather side of a cut fur. Pricking increases the durability and dimensional stability of the finished garment, particularly in the case of highly elastic or easily torn furs.

- Pump : the back of the skin

- smoke : Term for thick, not tightly lying hair. The smoke too

- Reinforcing : Darkening of the skins through treatment with metal salts, especially with lighter undercoats. The skins are still considered natural, i.e. not colored (especially for mink and muskrat )

- red : opposite → blue

- Plucking : The removal of the guard's hair (result e.g. velvet mink, velvet nutri, velvet weasel, formerly also common in the hair seal). For many years, as far as possible, also used on severed, worn mink fur

- Scissors : The shortening of the hair with clippers (result e.g. velvet bisam, pieces of velvet mink, beaver lamb , sealcanine ). Also possible with separated, worn fur

- Schnatte : A tear in the upper leather (grain break) on the fur side that occurred during peeling or dressing

- Beauty : Not pure white or yellowed white skins are chemically lightened, either by treatment with optical brighteners or with a reddish blue dye

- Thiliki : specially processed belly pieces, especially for mink and sable

- Refinement : Collective term for changes in the hair, e.g. B. by dyeing, plucking, scissors or the leather side by dyeing, napkin, velor, printing

- Dewlap : The underside of the fur

- Dressing : The tanning of skins for fur purposes

- Purposes : To smoothly stretch the pieces of fur moistened on the leather side after assembling the skins before matching (cutting into the final shape). Also Vorzwecken (the fur or skin of the strip), Umzwecken (in the form of tension in order to avoid dart ) and Abzwecken

See also

Web links

- Further information on the website of the German furrier guilds

- Technical book Der Kürschner , history and expertise of the furrier trade

- Lexicon for technical terms in skinning

Individual evidence

- ^ A b Paul Larisch : The furriers and their characters. 1928. Self-published, Berlin.

- ↑ Josef Winiger: The clothing of the ice cream man and more recent findings at the beginning of weaving north of the Alps. In The Man in the Ice: New Finds and Results. K. Spindler… [et al.] (Ed.). By Konrad Spindler, Frank Höpfel, Werner Platzer, contributors Konrad Spindler, Frank Höpfel Springer, 1995, ISBN 3-211-82626-2 , p. 119 ff.

- ↑ [1] Comfort in the Stone Age - How does Ötzi's clothing compare to modern functional clothing? Rose-Marie Riedl, IDW, May 25, 2007

- ↑ Bruno Schier : The names of the furrier. 1949, Technological Fur Dictionary No. 4, Hermelin-Verlag, Leipzig.

- ^ Jean Heinrich Heiderich: The Leipziger Kürschnergewerbe . Inaugural dissertation, presented to the high philosophical faculty of the Ruprechts-Karl-Universität zu Heidelberg, 1897, p. 35.

- ^ Karl Hansen: 700 years of furriers' guild Lüneburg 1250-1950 . Craftsmen's guild for the furrier, hat and cap-making trade for the administrative districts of Lüneburg and Stade (ed.), P. 7.

- ↑ Katrin Keller, Leipzig: Working and living conditions in the properly organized furrier trade - The example of Leipzig. In: Brühl. VEB Fachbuchverlag Leipzig, Issue 3, May / June 1989, pp. 29–31.

- ↑ One of the reasons why fur processing and production still take place mainly in Europe, and the Asian fur trade is still mainly carried out in the English-influenced Hong Kong .

- ↑ Without mentioning the author: The production process in the furrier trade. In: Kürschner Zeitung. No. 28, Verlag Alexander Duncker, Leipzig, October 1, 1933, pp. 598-600.

- ↑ In the opinion of the experts, this work of art by furrier work was the peak of what had been achieved so far . Journeyman working time 200 hours, seamstress 1000 hours. Although the fur sewing machine had already been invented, the seamstresses had sewn the outlet seams by hand.

- ↑ Franz F. Schwarzenstein: The woman in the fur trade. In: The tobacco market. Berlin, No. 96, p. 5 of August 12, 1930.

- ^ Ernst Kreft: Modern working methods in the furrier trade . Verlag Schiele & Schön, Berlin, undated (after 1950), p. 77. Book cover and table of contents .

- ^ Walter Fellmann : The Leipziger Brühl. Fachbuchverlag, Leipzig 1989, ISBN 3-343-00506-1 .

- ↑ Paul Larisch, Josef Schmid: The furrier craft. Self-published, Paris without year (first edition, part I 1903), p. 32.

- ↑ Magyar Scücs-és Szörme Almanac 1928/29 - Ung. Fur and Tobacco Almanac. Budapest 1929, p. 45.

- ↑ Joachim Kistner: 1972-1982. An important stage in the development of the tobacco industry in the GDR. In: Brühl. September / October 1982, Fachbuchverlag Leipzig, p. 31.

- ↑ Peter Plappert, Volker Gießmann (author of the chapters used here): The furrier trade on the threshold of the new millennium. Self-published, Hockenheim September 2000, pp. 20–23 (Chapters 6–7)

- ^ Lexicon of Old Crafts, From the Middle Ages to the 20th Century. Mechthild Wiswe , pp. 134-139

- ↑ www.pelz-leder-weis.de ( Memento of the original from February 28, 2008 in the Internet Archive ) Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice.

- ↑ Frieda Vallentin: Viennese chic in fur . In: Die Pelzkonfektion , March 1925, Verlag Carl Schmalfeld, Berlin, p. 32.

- ^ SW: The Viennese furrier . In: Die Pelzkonfektion , March 1925, Verlag Carl Schmalfeld, Berlin, p. 97.

- ^ Heinrich Lange, Albert Regge: History of the dressers, furriers and cap makers in Germany . German Clothing Workers Association (Ed.), Berlin 1930, p. 113.

- ↑ Paul Biwalski: A look into the green…. In: All about fur. August 1955, p. 19.

- ↑ The fur trade. 1964, Rifra Verlag, Berlin, Frankfurt / Main, Leipzig, 1964, p. 88.

- ↑ 100 Years Strobel 1883–1983 , self-published by Alfons Strobel, 1983.

- ↑ Paul Larisch, Josef Schmid: The furrier craft. II. Part aids. Published by Larisch and Schmid, Paris. P. 32.

- ↑ Cutsewmat. Pfaff brochure no. 296: We won't put a louse in your fur…. Kaiserslautern April 1983.

- ↑ Without the author's details : Again something new from Pfaff: After the automatic skin outlet, now the skin edge trimming device. In: The fur industry. Issue 4, April 7, 1982, p. 182.

- ↑ Woven fur trim : In the reel. Rifra-Verlag Murrhardt, born 1962, p. 8.