Semi-finished fur product

Fur semi-finished products , including fur semi-finished products or board product , are available for further processing into fur garments prepared surfaces made of fur or fur residues. Depending on their size or shape, they are traded as strips , tablets , plates , linings or bodies (technically: "the" body), formerly also as sacks , and from China as crosses and robes . Unprocessed, only tanned (trimmed) skins are no longer referred to as semi-finished products in the fur industry (in contrast to earlier times).

For a detailed description of the fur remnants (pieces of fur) that are regularly processed into semi-finished fur, see → Fur remnants .

General

The range of goods in the tobacco trade includes single skins and tableware or products traded under a similar name. Wholesalers usually bundle individual skins into coats or jackets before they are sold.

For the semi-finished products, individual hides or skin remnants are sewn together to form larger areas; Remnants of fur are the "waste" that arises when processing the core of a fur. These semi-finished products have various advantages. In terms of fur finishing , their size makes them more rational and easier to shear, pluck and dye. Large-area patterns applied by printing are only possible in this way. The amounts of fur available, in particular the amount of pieces of fur, are generally considerably greater than are available to furriers who operate in retail . The semi-finished products not only enable more efficient work for the table manufacturer and the finishing furrier, but above all, cleaner assortments in terms of color, hair structure and quality. These prefabricated products also benefit the needs of the finishing workshops to the extent that, given the short sales season, many more orders can be carried out there.

In addition to the pieces of fur, small pelts in particular are assembled into semi-finished products on top of and next to each other. These include skins from the mole , croissant-like , weasel , muskrat to slightly larger skins such as rabbit , kid , nutria , Persian or mink , the latter also only sewn next to each other, omitted to narrow strips in jacket or coat length .

If the material is also traded in assortments (fur bundles), models with a greater amount of fur are generally not made from tableware in retail stores. Likewise, cutting patterns with a somewhat unusual distribution of the pelts or guidance of the fur webs are more difficult to produce, in individual cases not at all from boards.

history

The manufacture of semi-finished fur products has developed considerably in China, Greece, Russia and Germany for a considerable time. Production in Europe is assured from the 13th century.

As early as the Middle Ages, the furrier in Central Europe was making fur lining in stock. The lining was later fitted to the customer by the furrier in an overskirt made by the tailor , the scabbard . The most popular material was feeh , the fur of the Russian squirrel. A stained glass window in Chartres Cathedral from the first half of the 13th century shows a furrier with an apprentice who offers his customers one of his fehwom chests kept in a chest (see illustration). Certain size regulations applied to a false bulletin. Each dewlap was cut to be about 14 inches long and four to five centimeters wide. About 120 pelts were required for eight rows or rows, so that the finished lining or the inner fur had a length of 112 centimeters and a width of 76 centimeters. At the end of the 19th century, the furrier called this activity, the assembling of small skins to make food tables, “the lines”.

In the 16th and 17th centuries, the name was Tafelmacher and board champion for the furriers, who engaged in the production of fur panels and coat linings. Originally they did not appear as independent furriers, but were employed by a furrier for this special work. In the late Middle Ages “they formed a middle link between master craftsmen and journeymen and were probably recruited from those who, because of their lack of resources or for other reasons, could not take the master craftsman's examination and saw themselves limited to the manufacture of semi-finished products in wage labor . They were the forerunners of the later dressers and bag rippers ”.

The sewing of the skins or the pieces of skin is done today with the fur sewing machine by specially trained workers. Despite the machine, this work requires considerable practice and manual dexterity. The fur sewing machine was invented in 1872. In the second half of the 20th century, hand-sewn panels came in particular from the important fur-producing countries of China and Russia.

It was only after the Second World War that panels began to be produced that were sufficient for a whole coat or jacket, so-called bodies. The further processing of bodies is even easier for the furrier than that of tablets and similar products, the main parts of the coat are already prepared. The impetus came from New York, where the German-born Kurt Seelig had started with body production. The product quickly became a major export item in the fur trade not only to the US and Greece, but also to the UK.

The wage-intensive piece processing is mainly widespread in the Greek province of Kastoria and in China, and pelt tablets also come predominantly from China. Both countries have a very long tradition in this. A center for the production of wide-tailed bodies is Israel. The London company M. Bardiger, on the other hand, was known for their muskrat and marmot bodies refined on mink, which they offered in outstanding quality. Also based in England was the Barmole company, which made tablets from the particularly good quality Scottish mole skins. In Germany and Austria, because of the high wage level, there is probably no longer any table or body production.

Germany

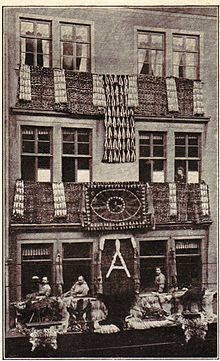

The street " Brühl in Leipzig " had the reputation of the "world street of fur" until the Second World War, was the most important street in the city and contributed significantly to Leipzig's international reputation as a trading metropolis. Around 1900, craft businesses had settled in and around Leipzig that served the Leipzig fur market. In addition to other fur dressing and finishing companies, these included many small furriers and intermediate masters who primarily produced fur for further processing on behalf of and for the account of the tobacco wholesalers. The production of fur linings was developed to the highest level in Leipzig, especially by furriers who immigrated from Greece. The production took place on a contract basis. In the factories around 1900 hamster food and food were still mainly produced by women, "whose hand is light and cheap enough to sew these small and delicate furs together". There were also individual tobacco wholesalers involved in manufacturing. In addition, there were also companies that processed pieces of fur that worked for their own account and bought the necessary material from furriers, the processing industry or from fur pieces dealers. Sometimes they outsourced the production to furriers and intermediate masters. The decline of the Leipzig fur trade began in 1933 with the expulsion of the Jewish entrepreneurs, who made up a considerable proportion of the companies. After the end of the Second World War, the importance of the Brühl for the fur industry was finally extinguished, almost all of the remaining wholesalers moved, often with a staff, from the Soviet-occupied area to the Federal Republic, where the new fur trading center Niddastraße was established in Frankfurt am Main . Some of the working companies and furriers also followed.

Even in the Middle Ages, the eye-catching hamster skin was often used for jewelry and plaster. The hamster furrier was called Grutschner at that time. Good hamster skins were particularly found in the Harz Mountains . Above all, the furriers there with their beautifully crafted hamster food made the item popular again in later times. The production of hamster food was still widespread in Central Germany until the GDR era. “Hamster furriers”, who also prepared (tanned) the skins themselves, were among others. a. in Aschersleben , Quedlinburg and Weißenfels . Since then, the fur tablets have probably only come from the Balkan countries, and most recently only from Hungary. There the skins are still processed by the furrier from the fur finishing to the fur lining in one hand.

After the Franco-Prussian War of 1870/71, Berlin became a leading fashion center. Fur clothing had settled around Hausvogteiplatz . Here, too, there were furriers who, in addition to the direct preparatory work for the manufacture with fur trimmings and fur linings, filled the so-called “quiet time” of the year with the production of tableware.

Austria

According to a description from 1944, at that time there was a piece foreman in the Viennese tobacco store (formerly known not only for Austria, also known as the bag ripper), which roughly corresponds to the Leipzig and Berlin intermediate master . He learned the craft of furrier and obtained full trade license by passing the master craftsman's examination. In his own workshop, he processes the material that is supplied to him by companies in the fur processing industry or the outerwear industry. He makes all kinds of fur clothing and is paid for it according to the tariff. He employs assistants and trains apprentices, but has no open shop and does not maintain his own warehouse, neither for skins nor for finished fur clothing.

The Viennese piece master is thus a wage worker in the same sense as the German intermediate master. However, while the German interim master still sees his main task at this time in assembling boards, strips and lining for the tobacco companies, this work was only occasionally performed by the piece master, according to the structure of Wiener Platz. While a piece master tariff, valid until the end of 1936, lists the production of coats, jackets, paletots, capes, collars, sleeves, trimmings, upper collars, cuffs, trimmings, hats, caps, men's furs, jacket linings and car furs , in addition to the individual types of fur, The manufacture of semi-finished products is not mentioned, not even later in the piece master tariff of 1951. The wages were calculated according to the type of garment, the number of processed skins and the type of skin treatment.

Before the Second World War (1939–1945) there were several hundred piece masters in Vienna who found their employment through ongoing orders from the fur processing industry. In many cases, former master craftsmen made the leap into their own warehousing with their own shop.

In the first decades after the war, the situation was similar to that in Germany. In addition to the pure piece masters, the furriers who worked for their own customers bridged the so-called "quiet time" (or "dead time") with wage labor, in which they made jacket and coat bodies in addition to ready-made fur. There were garment manufacturers who employed up to 30 self-employed furriers.

Greece

Whenever the fur industry talks about piece processing, it is usually synonymous with Kastoria , the Greek city near Albania. The second, smaller, 50 kilometers away, also involved in the sewing of fur pieces, Siatista is only known to a few. The fur leftovers, which are first and foremost waste products for the "normal" furrier, used to be the basic material for the Castorian furriers since the end of the Second World War.

After the Second World War (1939–1945), a fur industry increasingly arose in the prefecture of Kastoria, which was no longer focused solely on pieces of fur, but also produced tableware made of fur and fur. The number of fur factories there was around 2000 in 1972. In 1988, the total number of workshops in the areas in and around Kastoria and Siatista was given as 5000, which together employed 15,000 people. Around 80 percent of the people working in industry and trade in Kastoria County, an otherwise agricultural and forestry area, were employed in the fur industry in 1978. With the decline in fur sales in Europe, especially in the Federal Republic of Germany, and with the relocation of fur production to Asia, the number of people employed in the fur industry decreased considerably. However, according to a study provided by IEES Abe, the Greek textile and clothing industry, fur is still the number one export sector in western Macedonia (2012), despite falling numbers.

China

The production of fur and piece boards has a very long tradition in China, but details about it do not seem to be known. The export started very late, around 1900; Today the country is the world leader in the manufacture and trade of these items. In the early days, China's specialty was the delivery of semi-finished products of fur and pieces of fur in the form of robes, crosses and mats.

a) Robes

- A kimono-like garment can be made from the robes with little effort . Robes consist of two cross-shaped sheets of fur. One panel (it would form the front and back of the kimono) is larger in length and width. The second panel running across it (it would make the sleeves) is smaller. There is an opening at the intersection of the two lanes through which the finished robe can be pulled over the head.

b) crosses

- A semi-finished product similar to the fur robe, but the body part is only jacket length, the transverse part with the sleeves is the same as the robe and thus forms the longer side of the cross.

c) mats

- The rectangular mats correspond to today's Chinese tablets, about 120 × 60 cm, but very different in size.

In 1958, the delivery to the world markets is given for the following semi-finished products:

A. Of the lamb and sheep

- Lamb cut plates

- a) Lamb Leg Plates

- b) Lamb Head Plates

- c) Lamb Neck Plates

- d) Lamb Ear Plates

- Most of the production takes place in Kalgan . The plates are also sold as Kalgan Lamb Leg Plates, Kalgan Lamb Head Plates, etc.

- If leg parts are also processed from Chinese broadtail skins (see 1. bd), the products are also referred to as Karakul claw plates.

- Black Chinese Moiré Plates, also known as Black Chinese Broadtail Plates

- Mongolin tablets (Kalgan tablets; tablets from Inner Mongolia)

- Lambskin Crosses

- Lamb Leg Crosses

- Lamb Ear Crosses

- Lambskin Mats

- Lamb Head Mats

- Lamb Leg Mats

- Tibet Crosses

- Tibet Robes (Tibet Robes)

- Sheep Leg Plates

B. The kid and the goat

- Jehol lambskin tablets

- Kid Plates, Black, Gray (Kid Plates)

- Kid Crosses

- Kid Leg Crosses

- Kid Mats

- Goat Mats (Goat Mats)

C. From the cat (since December 31, 2008 trade ban and commercial import ban in the European Community)

- Cat Plates

- Leopard Cat Plates (Chinese Tiger Cat) (Leopard Cat Plates)

- Leopard Cat Robes

D. From dogs (together with cat skins since December 31, 2008, trade ban and commercial import ban in the European Community)

- Dog Plates

- Dog Mats

E. From the Chinese rabbit (white)

- Rabbit Crosses

F. Vom Pahmi

- Fur robes (robes)

Manufacturing

For the production of fur boards, fur linings and fur bodies, similar rules must be observed as for clothing items made directly from fur. In the first step, the skins are attached , that is, the natural or damaged areas are repaired. In each of the commercial forms, the same type of pelts are combined in terms of color, hair length, hair density, hair structure and size. In the case of different fur sizes, the largest of the selected pelts are placed in the bottom row, the smallest in the top. In terms of appearance, it is usually best to sort the darker pelts down. For a coat or jacket, at least according to the old kürschnerian view, the most beautiful furs are placed in the collar, in the right front part (with women's clothing this is also the step over ) and in the back.

Depending on the number of horizontal lines of fur on top of each other, the boards and linings are called three-, four-, five-liner, etc. In the case of hamster chucks that tear easily, the rare three-liner and four-liner are the most valuable, with otherwise the same quality, as they have the strongest leather. The skins are to be sorted next to each other according to color and hair structure criteria. Once the fur surfaces are sewn, they are stretched smooth by the furrier after he has moistened the leather. After drying and tipping, the parts are freed from loose cut hair in a shaking barrel and shaken soft. For wholesalers they are stitched together, either for one item of clothing or for larger, similar items.

A special type of processing for Fehwammen comes from China, called "Vintom" (= Russian: "screw"). The peritoneum pelts are worked diagonally in a helical shape, namely "half-skinned", that is, separated into right and left halves of the abdomen. These boards are always traded in pairs, each diagonally opposite. With all types of processing (full-skin, half-skin and vintom), a more or less wide part of the dark gray back is always left on the white belly parts.

Due to their larger surface, fur boards can generally be refined more cheaply, many types of refinement are only possible with fur boards. In the case of pieces of fur, it is obvious that processing thousands of individual small particles is hardly conceivable. They are usually sewn together to form two-part bodies, which are usually still easy to handle for the finisher in terms of size. Board, lining or bodies can be colored, blinded , plucked, sheared (or plucked and sheared), printed or lasered. With scissors or lasers, like printing, patterns can be created in the fur. If the upper hair is colored differently than the lower hair, very special effects are created when shearing.

Fashion also has an influence on the processing of semi-finished fur products. When, for the second time in the history of fur fashion, plucked or sheared furs, so-called velvet furs, were demanded for the second time at the end of the 20th century, muskrat processing, for example, was changed with some delay. Until then, when the pelts were placed on top of each other, the corners of the skin were "kicked in"; the upper skin was pushed a little over the lower skin when sewing it together in order to compensate for the difference in hair length. If the skins were sheared for the velvet finishing, the shearing knives would also grasp these corners, and the resulting areas often had to be reworked individually. Since the hair is shaved down to the lower hair anyway when shearing the fur boards, the occurrence was superfluous.

For furs that are reversible or that are only worn with the leather side facing outwards, the leather side is also treated. A napkin or a film coating make the garment rainproof. Any desired pattern can be applied by printing, which may help to conceal the seams that are annoying due to the repair of the skins and other seams.

Sizes

The usual dimensions vary depending on the fashion and intended use (jacket or coat) (each width x height).

- Body = coat 230 cm × 118 cm; Jacket 230 × 75 to 90 cm.

- Lining , usually made of fur only = 110 to 115 cm × 140 to 150 cm (mostly conical, narrower at the top).

- Rotunda and sack , like a rectangular lining, as a rotunda round (“double-sided”), as a sack, sewn closed at the bottom. Not common today.

- Table (also known as a plate for Chinese fur tablets) = 60 × 120 cm.

- Stripes = 1 fur width, or depending on the intended use, for example for hood trims. Mentioned in 1958: 120 × 45 to 50 cm, so strips are narrower than panels .

Some particularly small types of fur, such as moles, hamsters, suzlik and weasels, are mostly sold as bars. Other species, such as feh, muskrat, rabbit and kid, are traded both as skins and in tabular form. With some types of fur, the back and stomach (dewlap) are processed separately to form panels. For this purpose, the dewlap is “gouged” out of the rounded fur (muskrat, feh).

Remnants of fur are always pre-assembled as tableware, usually as a piece body, from China also as a piece board, formerly also as a cross or in coat length as a robe.

Depending on the shape, size and length, the following are required to produce a jacket:

- Strip goods: 9 to 10 strips

- Tableware: 6 bars

- Lining: 1½ to 2 linings

- Bodyware: 1 coat body.

The largest version of the tableware, the body, is used next to the piece goods mainly for types of fur that are in greater demand. These can be: mink, muskrat, American opossum , caloyos lamb, marbles, raccoons, rabbits, Persians, kids and similar varieties. Heads, claws and other pieces of all types of curly fur are also processed into bodies. In the time of Persian fashion, for example, Persian claw bodies were also very much in demand. Fur clothing made from precious goods , such as broad-tailed and Persian, is mostly made to measure in the retail trade by the furrier, but also made-to-measure. A body can consist of only one or two parts, which is regularly the case with pieces of fur. With fur bodies there are usually one or two sleeve parts. The fur bodies are often supplied with unprocessed, matching fur for the collar. The size of the body, in particular the length, is adapted to the respective fashion, the area should be large enough so that a medium size clothing can be made from it.

List of the types of fur processed into semi-finished products

With the multitude of fur types and types of fur suitable for fur and the change in fashion, the following list cannot claim to be complete, and the type of manipulation changes according to demand.

| Kinds of fur processed into semi-finished products (noted 1958!): | ||||||||

|---|---|---|---|---|---|---|---|---|

| Bodysuits | Panel | plates | Stripes | Lining | bags | Crosses (chinese) |

Robes (Chinese) |

Mats (chinese) |

| American opossum | Burunduk |

Broad tail (black Chinese moiré plates ) |

Seal muskrat (whole skins) |

Astrakhan | Feh (Ganzfeh) |

Rabbit |

Leopard cat (chinese tiger cat) |

dog |

|

Muskrat (natural and colored) |

Back |

Dog (chinese) |

Seal muskrat back | Pine marten throats | Back | Kid | Pahmi | Kid |

| Caloyos lamb | Fehwamme | cat | Seal muskrat | Pine marten paws | Fehwamme | Kidclaw | Tibetan lamb | lamb |

| Chinese Rabbit fur (colored) |

hamster | Kid u. a. Moiré (Chinese) |

Seal muskrat | Pine marten pages | hamster | lamb | Lamb Claw | |

| Chinese Weasel | Jehol-Lamm (Chinese Astrakhan ) (Kid-Astrachan) ( Tapanchang ) |

Lamb Claw |

Bueno lamb (less common) |

Muskrat | Lamb Claw | Lamb head | ||

| Feh | Kanin, u. a. Hermelin mimics |

Lamb head, lamb forehead u. a. |

Back (trimmings) |

Muskrat back | Lamb head | goat | ||

|

Marble (colored) |

Rabbit head | Neck of lamb |

Rabbits (whole Russian hare) |

Muskrat | Lamb's ear | |||

| Seal rabbit | Rabbit sides | Lamb ears | Saddle of hare, colored (Russian) (mainly for trimmings) |

Bisam (Ganzbisam; rare) |

Tibetan lamb | |||

|

Raccoon (natural, blinded, colored) |

Kolinsky | Leopard Cat chines. Tiger cat |

Rabbit dewlap (Russian) |

Muskrat cheeks | ||||

| Kid | lamb | Rabbit (seal nutria) |

Muskrat forehead | |||||

| Lamb Claw | Rabbit sides | Bisampumpf | ||||||

| mole | Rabbit back (less common) |

Muskrat pieces | ||||||

|

Mongolin ( Kalgantafeln ) |

Lambskin (less often) |

Burunduki | ||||||

| Persian Claw | mole |

Squirrel (european) |

||||||

| Persian claw tips | Persian Claw | Feh | ||||||

| Sheep claw | Suzliki | Square head | ||||||

| Shiras Claw | Back | |||||||

| Suzliki | Fehwamme | |||||||

| Kid | Fox | |||||||

| Kid claw | Fox paw | |||||||

| Fox pieces | ||||||||

| hamster | ||||||||

| Polecat | ||||||||

| Rabbit (natural, colored, SEAL) |

||||||||

| cat | ||||||||

| Kid | ||||||||

|

Rock badger (rarer) |

||||||||

| Kolinsky (less often) |

||||||||

| Krestowatiki ( variety of white fox ) |

||||||||

| Marble (natural and colored) |

||||||||

| Marble pieces | ||||||||

| Native Cat | ||||||||

| mink | ||||||||

| Mink throat | ||||||||

| Mink head | ||||||||

| Mink pump | ||||||||

| Back of mink | ||||||||

| Mink sides | ||||||||

| Nutria | ||||||||

| Nutriaseiten | ||||||||

| Possum | ||||||||

| Opossum pieces (rarer) |

||||||||

| Pechaniki | ||||||||

| Pijiki | ||||||||

| Ringtail | ||||||||

|

Dormouse (less common) |

||||||||

|

Skunk (South American) |

||||||||

| Suzliki | ||||||||

| Feast | ||||||||

| racoon | ||||||||

| Beech marten throats | ||||||||

| Beech marten paws | ||||||||

| Beech marten pages | ||||||||

| Viscacha | ||||||||

| Viscacha head | ||||||||

| Viscacha pages | ||||||||

| Wallaby | ||||||||

| Wallaby pieces | ||||||||

| Weasel (Chinese, Japanese Solongoi) |

||||||||

| Kid | ||||||||

| sable | ||||||||

| Sable throat | ||||||||

| Sable Claw | ||||||||

| Sable sides | ||||||||

| Pieces of sable | ||||||||

| Civet cat | ||||||||

| List of semi-finished fur products in China (English, around 1980?) | ||||

|---|---|---|---|---|

| Kalgan Lamb Plates | White Slinksheep Skin Plates | Hei Yao Skin Plates | Tsining Kid Head Plates (Gray, White, Black, Mixed) |

Pahmi Head Plates (plucked and unplucked) |

| Tientsin Lamb Skin Plates | Chekiang Lamb Skin Plates | Plucked Badger Skin Plates | Tsining Gray Kid Head Skin Plates Diamond Shape |

Raccoon Leg Plates |

| Peking Lamb Skin Plates | Dog Skin Plates | Plucked Raccoon Skin Plates | Lamb Leg Plates | Raccoon Neck Plates, plucked |

| Shantung White Lambskin Plates (Type AC) | Plucked Hare Skin Plates | Pony Skin Plates | Shantung Lamb Leg Plates (White, Mixed) |

Civet Cat Neck Plates (plucked and unplucked) |

| Pearl Lamb Skin Plates | Antelope Skin Plates | Standard Mink Skin Plates | Kid Leg Plates | Various Kinds of Rabbit Piece Skin Plates |

| Kidskin Plates | Abortive Calf Skin Plates | Kolinsky Skin Plates | Tsining Kid Leg Plates (Gray, White, Black, Mixed) |

|

| Tsining Gray Kidskin Plates, Chevron Made | Shantung Dog Skin Plates | Weasel Skin Plates | Tsining Gray Kid Leg Plates, Chevron Made | |

| Tsining Gray Kidskin Plates (Yellow, Gray, Mixed) |

Inner Mongolian Dog Skin Plates | Fitch Skin Plates | Cat Leg Plates | |

| Rabbit Skin Plates (White, Black, Mixed) |

East China Dog Skin Plates with Design | Laska Skin Plates | Cat Neck Plates | |

| White Rabbit Skin Plates, Chevron Made | Designed Dog Skin Plates (Yunkwei, East China and Northeast China) |

Squirrel Skin Plates | Peking Black Lambskin Plates (Type AB) | |

| Beaver Rabbit Skin Plates (White, Gray, Brown, Black, Mixed) |

Kiukiang Civet Cat Skin Plates, Plucked | Pine Squirrel Skin Plates | Leopard Cat Leg Plates | |

| Chinchilla Rabbit Skin Plates | Civet Cat Skin Plates, Plucked | Muskrat Skin Plates (Back, Belly, Head, Chevron Made) |

Leopard Cat Neck Plates | |

| Hare skin plates | Fox Skin Plates | Buranduki Skin Plates | Leopard Cat Belly Plates | |

| Raccoon Hare Skin Plates | Northwest China Fox Skin Plates | Tree Squirrel Skin Plates | Chin Yao Leg Plates | |

| Northeast China Goat Skin Plates | Liao Tong Fox Skin Plates | Yellow Rat Skin Plates | Huang Yao Leg Plates | |

| Shantung Goat Skin Plates | Liao Si Fox Skin Plates | Mountain Rat Skin Plates | Tibet Lamb Leg Plates | |

| Kalgan Goat skin plates | Pahmi Skin Plates | Leopard Rat Skin Plates | Lamb Ear Plates | |

| Plucked Goat Skin Plates | Plucked Pahmi Skin Plates | Lamb Head Plates | Lamb Neck Plates | |

| Sheared Sheep Skin Plates | Marmot Skin Plates | Lamb Head Plates | Lamb Thigh Plates | |

| Designed Sheared Sheep Skin Plates | Ching Yao Skin Plates | Shantung Lamb Head Plates (White, Mixed) |

Pahmi Leg Plates (plucked and unplucked) | |

| Tibet Lamb Skin Plates | Huang Yao Skin Plates | Kid Head Plates | Pahmi Neck Plates (plucked and unplucked) | |

See also

Individual evidence

- ↑ Alexander Kislatis: Study on the history, development and operation of the tobacco trade with special consideration of Germany . Inaugural dissertation of the High Law and Political Science Faculty of the Hamburg University, Hamburg 1926.

- ↑ a b c d e f g h i j Paul Schöps among others: Semi-finished products from Fellwerk . In: Das Pelzgewerbe 1959 No. 2, Hermelin-Verlag Dr. Paul Schöps, Berlin et al., Pp. 58-69.

- ↑ Peter Melchers: The wholesalers in the tobacco industry. Westkulturverlag Anton Hain, Meisenheim / Vienna 1953, p. 48.

- ↑ a b c Samuel Serter: The Shell . In: Fur Review , September 1982, pp. 27-28 (English).

- ↑ Simon Greger: The furrier art. 4th edition, Bernhard Friedrich Voigt, Weimar 1883, pp. 43–45. (130th volume in the New Scene of the Arts and Crafts series ).

- ↑ Alexander Tuma: Pelz-Lexikon. Fur and rough goods. XXI. Tape. Verlag Alexander Tuma, Vienna 1951. Keyword "Tafelmacher"

- ^ Jean Heinrich Heiderich: The Leipziger Kürschnergewerbe . Heidelberg, 1897, p. 187. Accessed March 20, 2016

- ^ Francis Weiss : From Adam to Madam . From the original manuscript part 1 (of 2), (approx. 1980 / 1990s), in the manuscript p. 284. (English).

- ↑ Color sample card from the Barmole company.

- ^ Albin König: The furrier in Frankenberg in Saxony . In: Studies on the situation of the craft in Germany . Second volume, Duncker & Humblot publishing house, Leipzig 1895, p. 321.

- ↑ (Unger-Khull 310a). German dictionary by Jacob Grimm and Wilhelm Grimm , 16 vols. [In 32 partial volumes]. Leipzig: S. Hirzel 1854-1960. - List of sources 1971.

- ^ According to information from the company Csányi Szörme Kft., Sződ and Budapest; Hamsterkürschner March 8, 2008

- ↑ Alexander Tuma: Pelz-Lexikon. Fur and Rough Goods, Volume XXI . Alexander Tuma, Vienna 1951, p. 192, keyword “piece master” .

- ↑ a b c Editor: The Wiener Stückmeister . In: Der Rauchwarenmarkt , No. 9, Leipzig, September 1944, pp. 3-4.

- ^ Central homeworkers' commission for clothing production: The piece master tariff . In: Register of furriers, cap makers u. Tobacco dyers in the fashion guild , Hsgr. Wiener Pelz-Rundschau , approx. 1936, pp. 18–27.

- ↑ Piece master tariff (minimal tariff), agreed between the federal guild of furriers, glove makers and tanners and the professional association of the clothing industry in Austria on the one hand and the representatives of the master craftsmen on the other for [...]. In: Landesinnung Wien (Hsgr.): Yearbook of furriers, glovers, tanners, cap makers, sackers, taxidermists and rough goods dressers and dyers 1954 , pp. 169–178.

- ^ A b Christian Franke, Johanna Kroll: Jury Fränkel ´s Rauchwaren-Handbuch 1988/89. 10. revised and supplemented new edition, Rifra-Verlag Murrhardt, pp. 377–378.

- ↑ Primary source in Pouliopoulos, p. 10: Census results of March 14, 1971 , published by the National Statistical Office of Greece, Athens 1977, p. 83

- ↑ omogeneia.ana-mpa.gr June 6, 2012 (Greek) . Retrieved June 28, 2012

- ^ Animal By-products . China National Native Produce & Animal By-products Import & Export Corporation, undated, pp. 20-26.