Dawn

lamb , mink, skunks and muskrat

The opening , formerly also using or braking , in Austria also called bribery , describes the first step in fur production in skinning , the "making usable" of tanned skins by removing damaged areas that would impair the appearance or durability of the end product. This is done by cutting out the areas in ellipses , inserting pieces of fur or closing the missing surfaces using other suitable working techniques, such as pulling the tongue or, very rarely, repositioning. At the same time, natural parts of the fur that interfere with the end product are removed, such as the mane in foal fur or the cervical vertebra in calf fur . The final sewing is done in specialist companies today with the fur sewing machine, as in hand sewing with an overlock stitch .

General

- Calfskin, removing the neck and forehead vertebrae by turning the head part

Damage to skins can have many different causes. They can be caused by bites or other injuries in the living animal, by gunshot holes, by cuts when deforming or trimming the fur, or by improperly stretching and drying the raw fur . Offspring positions (growth, undergrowth) can also be disruptive and must be eliminated. Bald spots occur most frequently, called "Kahlauer" by the German-speaking furrier. The skin trade calls the thickened areas of scarring left behind by an injury to the skin "plasters", although there is probably no specific term used in skinning.

The imperfections to be removed can be:

- In the hair:

- Bald spots (pelts, bald spots), thinly haired, rubbed or matted spots, new growth or growth, shear or color defects, mane, vertebrae, teats and the ramming spots on hamster fur .

- In the leather:

- Bite marks, butcher cuts, bore holes (damaged by pests, including by beetles, worms, rats, mice), bullet holes, errors caused by so-called burning or Verstinken (hard, partly bald spots, rot damage in raw hide) Schnatten (incisional hernias in the upper hair side) teat holes , Cracks and dressing seams.

The full extent of the damage usually appears for the first time after the repair. Sometimes the damage only occurs during dressing; thin-leather skins are more sensitive to this than heavy-leather skins. Depending on the shape of the damaged areas, they can be removed to a certain extent using special cutting techniques. Ideally, the repaired areas should not be visible on the hair side. As long as the areas to be filled are not too big, this is technically possible with soft and not too short hair (for example with fox fur , raccoon fur , mink and similar hair structures). In the case of very hard or very short hair, the seams are often visible, which is why seams are kept as small as possible here (for example in seals, especially in short-haired, sheared Lakoda seals, in flat broad- tails , here especially in thin-haired, unmoured Galjak ). The attachment points in lakoda, broadtail and galjak skins therefore often have to be closed in a time-consuming manner with finer hand seams.

Philipp Manes , the fur commissioner and historian of the fur industry who was murdered by the National Socialists, wrote in 1941: “The 'Anbrachen' des fur, d. H. patching up and eradicating bad spots requires a trained eye. An experienced starter can save many thousands of marks if he knows how to repair every skin at a glance and quickly. Look at a gallon silver fox that, cut into narrow strips, doubles depending on the length or width. Or the most expensive mink fur , as it is exuberantly valuable and beautiful. "

The extent of the damaged hides in the individual batches of goods as they come onto the world markets varies depending on the quality level. Best and better varieties (I and II) show less damage. The best qualities are often free of any damage to leather and hair; this is now the case, for example, for almost all breeder's pelts that are delivered. Lesser varieties (III, IV, V), but especially "damaged" ones, sometimes contain a lot of damaged skins, according to the standards of the 1950s that was up to 50 percent of a batch, with damaged up to 100 percent.

In most cases, more substantial damage is already removed by the tobacco wholesalers. Larger companies maintained their own furrier workshops for this purpose, also called anbrache workshops. In many cases, the damaged skins were also given to an intermediate master outside the house to be opened . Persons employed in the Anbrachkürschnereien workers who often had no full vocational training but had been trained only for this work were as Anbracher, or sometimes by the activity of the smooth tensioning of skins, as Zwecker referred. When the pelts come to the furrier, sorted in fur bundles, they are usually free of major damage. Only the thin, leathery and lightly haired broad-tailed skins are only attached by the end processor.

Work techniques

English girls stretch rabbit skins during World War II

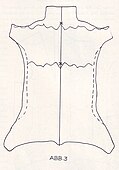

A large number of pelts are still closed round after fur trimming when they come to finishing. As a rule, these are the more noble types of fur, especially the species of marten, as well as the mink, unless they have already been cut open during processing, such as shearing, plucking or dyeing, and thus laid flat. Except for a few types of fur, such as the lynx fur , earlier the Desman fur , sometimes the nutria fur , where the peritoneum is more beautiful than the back, all are cut open in the stomach. This must be done exactly in the middle of the stomach. Exceptions can be skins of types in which the belly cannot be used because the hair is too thinning, such as skunks fur or possum fur , here the part of the belly is cut out directly when cutting open. Another exception are the types of fur in which the back and dewlap are processed separately, such as muskrat and mud fur . Here, in particular, it is important to ensure the greatest possible evenness so that both the dewlap and the back do not get crooked. If possible, a wooden sheath that is tailored to the skin size is inserted, for example a mink sheath, or, if not available, a ruler. This prevents the back of the fur from being accidentally caught when cutting. With the hairline, starting at the head, the fur is cut open with the skinning knife, the edge upwards. Then, as a rule, two cuts are made to the front paws so that the paws are now on the sides of the fur.

The actual opening is preceded by the marking of the groan , the middle of the coat, which usually differs in color and often in hair length. This is done from the hair side with the copy wheel, by marking with pins, hardly with the grunt. Another common method is to lay the fur with the combed-up hair on the worktop, press the furrier's brass comb onto the fur with the prongs and pull the fur over the plate with a short jerk. Each of these methods leaves a mark on the leather side, which is fixed with a dashed line. In addition, it often makes sense to mark other distinctive fur drawings for further processing, especially the cross section at the level of the front paws.

Sharp kinking of the fur, combing up and blowing on the hair will not directly find any noticeable bald, felt or other damaged areas. Various devices that do the blowing by machine had already been developed in the first quarter of the 20th century, but did not catch on. Depending on the structure and value of the fur, the damaged area is marked from the side of the hair: with pins; the Grotzenstecher (the furrier's awl); as when marking the groan with a comb by pressing on with the rear tip of the blade holder while simultaneously pulling it briefly over the worktop or by "piercing" (more rarely: "bribing") with a skinning knife . Or they are cut out directly from the hair side, otherwise according to the markings from the leather side. Cross- cuts are to be avoided because they mark the most, especially because of the hair that is taken out of its natural position when sewing with the fur sewing machine . Instead of a rectangle , the aim is therefore to achieve the shape of a parallelogram when cutting out the defect . Except for the repair by means of an ellipse, all imperfections must be cut out in an angular, geometrically regular shape, curves can be sewn less well and cleanly with the fur sewing machine.

In the process of opening some types of fur, the thieves , the mostly less hairy areas at the base of the paws ( Persians ), may also be cut out.

Except when inserting suitable pieces, the damaged areas are removed, but the cut-out part of the skin is not really replaced. Warps are created in the leather, it is no longer flat. The fur is smoothed again by a subsequent damp stretching (for purposes ) or stretching , while the damp seams are flattened with the seam roller or the stretching wood . The special tanning of the pelts, the fur finishing, takes this requirement on the fur leather into account by producing a leather that is as swift as possible when it is wet for the furs that are worn outside with the hair. Velouty furs with the leather side facing outwards must not change when wet and are accordingly prepared differently, however, for visual reasons, they are usually not attached (seams on the outside of the garment) without bald spots in the hair.

Ellipses

Small areas are cut out in the form of an ellipse and sewn up. In the simplest case, it consists of a cut through the defect, after which the unevenness is leveled out with scissors. The slightest seam marking usually causes the longitudinal seam or the ellipse laid along the course of the hair, only if nothing else is possible, the ellipse will be laid diagonally or across. It should be noted that this does not cut out any color or hair length transitions, especially in the case of an ellipse running diagonally to the direction of the hair. If possible, there should not be multiple ellipses next to each other, ellipses lying next to each other should not be of equal length.

One of the exceptions are rabbit fur intended for shearing , here all cuts should be made as diagonal as possible. The fur refiner justifies this with the fact that the reticular layer of the dermis is better to straighten smoothly in the case of diagonally lying cuts and the bag formation that occurs with longitudinal cuts is avoided, which would lead to miscarriage in these places when shearing.

Insert piece (pieces)

Particularly with curly fur, cutting it out is the preferred type of repair, especially with larger bald spots. A suitable piece of fur is used with parts of other fur of the same type of material and structure, if possible in a triangular shape, which can be sewn most efficiently and cleanly. If the fur is not curled, it will rarely be possible to find a suitable piece from the same part of the fur. In order to compensate for the seam loss, the pieces to be inserted must be about three to four millimeters larger than the hole to be filled in each direction, lengthways and crossways.

Pulling tongue (wedge cut)

The tongue, also referred to as a triangle, is very often used when breaking the skins. Only with very short-haired material ( broad tail , flat calfskin or flat foalskin ) is their use prohibited. It can also only rarely be used on skins that have a very distinctive mark (ocelot). A suitable piece must be used here.

Tongues are also used to change skins into more manageable shapes. As a typical example, a reference book "in the surfacing of the front claw section and the Pumpfes at Nutria, the castle game in called muskrat and Pumpfpartie at Skunks " ( Pumpf = the rear fur game, there are also the flaxen-haired "castle" in the muskrat).

If you follow the master furriers and trade teachers Malm and Dietzsch (* 1900; † 1993), then shortly after 1850 it was the furrier Leberecht Giese from Leipzig who first cut a "lateral tongue" (on the edge of the skin) and thus the development of today's "Tugging" started. The journeyman worked for the Starke company in the “Zur Goldenen Kanne” office building, Richard-Wagner-Strasse, on the site of today's “Seaside Parkhotel”. Against this, however, is the fact that as early as 1837, for the master craftsman's examination in the prince-bishopric of Würzburg, among other things, it was required to " leave out " a pine marten with twelve tongues to the length of one cubit , an already significantly more demanding technique of skinning.

Simple tongue

If the damaged area is too large, one or more tongues can be pulled to close the hole that has emerged after removing the area. To make it more hairy, the area to be repaired is cut out as a parallelogram, the sloping edge across the hairline. A tongue has the shape of an acute triangle. Immediately behind the repair point, it should still be the same width (different from what is shown here), and then taper towards the end. It should not exceed an angle of 20 °. When sewing, it is moved into the hole created by the cutting out, the gap created at the end of the narrow wedge is sewn up. The amount of back removal and the size up to which a hole can be closed with tongues depends on the individual color and hair structure as well as the speed of the fur leather. In order to achieve a good, i.e. non-marking result, the length of the under hair is usually assumed as the maximum back distance. This can be more within the same hair structure, and less if the hair is very uneven. Therefore, color and hair length limits must be observed; if necessary, they must be copied from the hair beforehand and drawn on the leather side. Whether the tongue is placed towards the head or the pump side also depends on this aspect. For example, in species of marten ( mink , sable ) and fox species, the usually flatter and darker neck area must not be moved into the longer-haired rear area of the back - and vice versa.

Double tongue, stair tongue

If there are several tongues for a repair point, the individual back distances are marked for the sewing process. As a rule, the furrier does not cut the individual parts completely apart when opening, but leaves them tightly connected at the ends until sewing.

A hide is structured differently in the different parts of the skin. In particular, from the middle of the fur to the sides, the hair color and length can change quite considerably within a centimeter. For this reason, the tongues must not be shifted (pushed) too far, as otherwise differences in color or hair length will become annoying. If the hole is very long, several tongues can be wrapped around each other to reduce the back distance for the individual cut (similar to skipping skins). The same can also be done from the opposite side of the hole, usually parallel to the middle of the skin. If a damaged area is of different lengths, it is advisable to close it with two tongues lying next to each other (stair tongue), also in the case of wider damage. Tongues lying next to each other should end differently in order not to take away the width in just one place.

Moving closer together

In the case of very badly damaged pelts, it is occasionally possible to connect the cut-out areas of the same length by making cuts and to move them together, shortening the pelt by letting it in , the opposite technique of lengthening it by leaving it out.

A good example of moving closer together is the nutria skin. Usually the teats lying on the back of the nutria can be removed with oblique ellipses. However, there is often a larger, bare or discolored halo around the nipples. Then it is advisable to connect the one behind the other with cuts, on the respective skin half the left side of the hole with the right side of the next hole, and to move the resulting step ladder together (stair cut).

Moving (knocking over, moving, transporting with the tongue)

The idea of supplementing a larger area of skin with skin material from the opposite side of the same skin is described again and again in the specialist literature, but in practice it should rarely lead to a good result. Despite the greater effort, it is tempting, it may save a fur that would otherwise not be used and keep the fur halves the same size. The hairline of the fur alone, which changes to the sides, makes the task problematic. If the hair on the left half is turned to the left, the fur material obtained there is sewn into the exactly opposite structure on the right side.

The one-sided defect is leveled out to a square or rectangle and transferred in half the width to exactly the same place on the opposite side. The area drawn there is cut into longitudinal strips of an even number (2, 4, 6, etc.) approximately 5 to 10 millimeters wide. These are sewn in reverse order on the opposite side so that an equally large hole is created in both halves in the same place. These two holes are closed with one or more tongues as described above.

Plug

Small, thin-leather broadtail and galjak skins occasionally have larger areas in which many snakes lie together (snatten fields). If it makes economic sense to use these heads as well, the areas are stuffed with a short, fine sewing needle. With hand seams, the individual slats are pulled together by flat stitches on the leather side, it is flat stitch by stitch on top of and next to each other.

history

- Show

"Opening of all kinds of skins [...]"

(Willi Trotte from Markranstädt , 1922)

- In an internal trade dispute, the Leipzig furriers object on August 19, 1794:

"Etc. etc. Whereas we quoadb. [with regard to] have to note that the term 'tobacco products' is a craft term and means nothing else than to cleanly cut and sew the holes found in the preparation of the goods, and this work, as well as the bribing and dragging of the goods over the Boards that are part of the preparation of the tobacco products and make up part of the same. "

- The furrier Wilhelm Schnell, born in 1884, reported from his fifth year as a journeyman when he worked in Vienna: “In February I got a job in a finishing shop as an Anbracher work. Since I was only paid 13 kroner a week, I had to take some of my savings in order to be able to live. ”In the skinning workshop he had last earned 40 kroner a week in a small retail shop, albeit with a lot of overtime every day - the 9-hour day had just been fought for - On Sundays they worked there until 12 noon and at the end of the season, on January 15th, he was dismissed due to lack of work.

- In addition to other companies, the rough goods dealer and fur manufacturer Ignaz Lustig in Vienna also offered a machine for blowing on while opening. He promoted this in 1926:

“No more lung-destroying bubbles when bribing!

If you use the latest bribery machine 'PIL'!

Come and have a look! "

- A table is shown on which the skin is to be drawn over a pen above which the air nozzle is located. Behind it is a suction funnel that conveys the hair into a fabric filter bag under the table. The machine is triggered by kicking.

- In 1954, in a historical review of a specialist publication: “Technically not fully trained, so-called. unskilled workers, if they are employed in pieces processing companies (anbrache-furriers), are also referred to as anbracher or purposes . "

See also

Web links

Individual evidence

- ↑ Alexander Tuma: Pelz-Lexikon. Fur and rough goods. XVII. Tape. Verlag Alexander Tuma, Vienna 1949. Keyword "Anbraken"

- ↑ a b c d e f g h i Author collective: Tobacco manufacturing and fur clothing . VEB Fachbuchverlag Leipzig 1970, pp. 286–292

- ^ Rudolf Gujer-Müller, revision Rudolf Gujer: The treatment of hides, skins and raw fat . Graphic workshops HR Sauerländer & Co., Aarau, 1938, p. 59.

- ↑ a b c d e August Dietzsch, Kurt Häse, Paul Schöps: Das Anbrachen . In: Das Pelzgewerbe No. 2, 1956, Verlag Dr. Paul Schöps, pp. 61-66.

- ^ Philipp Manes : The German fur industry and its associations 1900-1940, attempt at a story . Berlin 1941 Volume 4. Copy of the original manuscript, p. 147.

- ↑ "z": apprenticeship training. Cutting and attaching skins . In: Die Kürschnerfibel , Verlag Alexander Duncker, June 1, 1942, pp. 17-18. Supplement to the Kürschner-Zeitung , issue 16.

- ↑ Alfred Homuth: About making fur usable . In: Kürschner-Zeitung , issue 25, September 1, 1941, Alexander Duncker publishing house, Leipzig.

- ↑ Device for examining the hair side of fur skins . German Reich patent No. DE461505 C, (sewing machine) company M. Rittershausen, Berlin O 27, Markusstrasse 5. Published June 25, 1928 . Retrieved August 30, 2015.

- ^ August Dietzsch: On the manufacture of Fellwerk . In: Das Pelzgewerbe No. 6, Verlag Dr. Paul Schöps, Berlin and Leipzig, p. 198.

- ↑ a b Author collective: Der Kürschner. Technical and textbook for the furrier trade. 2nd revised edition. Published by the Vocational Training Committee of the Central Association of the Furrier Handicraft, JP Bachem Publishing House, Cologne 1956, pp. 29–31

- ↑ a b Alexander Tuma jun: The furrier's practice . Published by Julius Springer, Vienna 1928, pp. 34–44

- ^ Friedrich Malm, August Dietzsch: The art of the furrier. Fachbuchverlag Leipzig 1951, p. 92.

- ^ Paul Schöps, manuscript of February 17, 1978: Meisterstücke . Pp. 3-4. G. & C. Franke collection

- ^ Secondary source : Jean Heinrich Heiderich: Das Leipziger Kürschnergewerbe . Inaugural dissertation, Ruprecht-Karls-Universität zu Heidelberg, 1897, p. 16.

- ^ Wilhelm Schnell: Wilhelm Schnell, Berlin . In: The German fur industry and its associations 1900-1940, attempt at a story . Berlin 1941 Volume 4. Copy of the original manuscript, p. 292.

- ^ Advertisement in: Wiener Kürschner-Zeitung , Alexander Tuma, Vienna July 25, 1926, p. IV.

- ↑ Paul Schöps: needle furrier - Galanteriekürschner - Lining furrier - Anbracher . In: Das Pelzgewerbe - Festschrift for the Kürschnertag des Handwerks Leipzig 9.-14. May 1954 . Hermelin-Verlag Dr. Paul Schöps, Berlin, Leipzig, p. 33.