Beaver lamb

Sheared sheepskins and the products made from them are traded as beaver lamb , especially clothing that is similar in appearance to plucked beaver fur . Beaver lamb is probably the best-known refined product made from sheepskin. The term "lamb" is common in the fur trade for sheepskins of all ages, the beaver lamb is the skin of adult sheep.

However, the terms beaver lamb as well as Mouton doré ( Mouton d'Oré ) have been declining in usage since the finishing method is predominantly only used as the basis for velor and nappa finishing. The product treated in this way is often offered as merino lamb .

Fine-wool, thick-haired, light-leather, merino sheep-like sheepskins are particularly suitable for this high shear. When processing into velor or nappa lamb, the hair quality does not have the same meaning, as the clothes made from it are worn with the hair inside.

history

In the Austro-Hungarian region, together with the Balkans, artfully crafted lambskin clothing has a long tradition. The special thing was the elaborate embroidery, with which the vests, jackets and coats of the peasantry were adorned, especially the festive clothing. The hair pattern was always left natural, largely shaggy, corresponding to the sheepskin. Long-haired lambskins and sheepskins, with the hair inwards, artfully embroidered on the leather side, were used for the traditional fur coats and jackets of the Eastern European countries. They were simply cut and were mostly closed with hussar locks. In this version, the bare furs were used as shepherds 'coats, often worn with the hair facing outwards, and with the leather facing outwards as the railway workers' uniforms. The long-haired fur was often used as decorative trimmings and trimmings at the same time; the leather was either natural, bleached or colored. Since the skins often come in large numbers from Afghanistan, wholesalers also call them Afghans . With hair straightened by the fur refinement, they are still used as trimmings and trimmings, especially for youthful clothing.

In the 20th century, however, people in the fur dressing shops became increasingly “obsessed with processing, innovations shot up like mushrooms”. The fashion of wearing furs with the hair on the outside began in 1842 with a seal jacket . For this use, the guard hair was removed from the seal skin, revealing the even, velvety under hair. In the future, all possible types of fur were made similar to the seal fur in this way, especially the rabbit fur as "seal canine ". In this fashion epoch, which came to an end after the Second World War , the inexpensive beaver lambskin, which was easy to process over a large area, was an excellent fit. By 1935 there were already several companies producing nutria and beaver-like sheep refinements under different names. First, a company succeeded in imitating the nutria fur removed from the awns , which was traded as "Nutriette". This was significantly improved when the Liftschütz & Zickerow company came up with the idea of ironing the lambskins. The company is therefore considered to be the initiator of the beaver imitation, known as “Mouton d'Oré”. Following the example of the velvet (velvet) ironing machine, Dr. Hans Müller, Leipzig designed the first fur ironing machine in the 1920s, which after improvements soon became one of the most important hair finishing machines in the tobacco industry. However, there was the deficiency that when the hair became frizzy again and the shine disappeared when it was damp.

Even though the article was further developed in terms of finishing technology, the main deficiency remained unsolved for a long time, namely that the coat lost its shine in the rain and became frizzy again. The Hungarian Fogl happened to become acquainted with a fur refiner who described the problem to him. Fogl thereupon developed a means and procedure which eliminated all difficulties. The essence smelled unpleasant and pungent, but was received with great interest by all the refiners to whom he offered it. But nobody wanted to buy it from him, every company hoped to figure out the secret on its own, but without success. Ultimately, the recipe for the so-called fixing process was acquired by the Budapest company Pannonia before the Second World War, and the product was given the brand name “Pannofix”. There were subsequently a large number of imitations, for which the Hungarian company conducted many patent protection proceedings. The names of other suppliers were “Fokafix” from the Viennese fur finishing company J. Foggensteiner, “Biberol” for an imitation beaver on shorn fur, “Biberon”, “Bibus” etc. In the GDR, a corresponding sheep refinement was traded as “Nutrofix”, based on the the nutria fur, similar to the plucked beaver fur, after the awn hair has been removed . The original finishing process, which was expensive compared to the fur value, is still used in principle today, but has been continuously improved since then.

At Leipziger Brühl , the place where almost all types of fur were universally trimmed and refined until the Second World War, it was only "too late" that the future importance of the low-value types of lamb and sheep was recognized, a fur finisher stated in 1974. In North America, after the end of the Second World War, the fur trader Motty Eitingon popularized the beaver lamb in a huge campaign, see → "Motty Eitingon # Last big deal and final business deal" .

During World War II made clothes from Mouton also the German, American and English soldiers good services, such as wearing parts English pilots of the Royal Air Force as an aviator fur short reversible jackets Mouton, later as so-called bomber jackets found its way into everyday fashion. Elisabeth Ewing even counts the material among the few good things that have emerged from this war. After it became obsolete as military fur, it became an attractive fashion item well into the 1980s, selling at four times its original price in its prime.

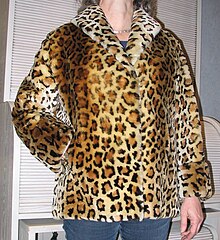

The new finishing meant a remarkable change for the sheepskin. Until then, sheep was largely a purely functional fur, worn by farmers and shepherds and on sleigh or carriage rides, but now it has moved into the more inexpensive but more sophisticated fur fashion. At the beginning of the 1950s, skinned furs were very fashionable and wages were still quite low, the then essential furrier textbook pointed out that after a refinement to “ phantom fiber ”, the skin can be skimmed “like the real material with excellent effect”. Additional refinements were added. The skins were not only dyed or, as for phantom colors, additionally provided with a darker middle grot , but also printed, as ocelot or leopard lamb . All these color refinements are summarized in the trade under the generic term beaver lamb.

A review of fur fashion in England in 1981 said: “After the end of the demands of the war, there was a return to the traditionally imported furs in fashion, but the beaver lamb, still turned, was the origin of the velouted sheepskin coats , Jackets, vests and other items of clothing that appeared in the 1950s, they are still an important part of almost every wardrobe for people of all ages, classes and types. "

Velouted, or additionally napped, beaver lamb has become an indispensable part of fashion. Depending on their origin, quality or finishing, they are traded under terms such as merino lamb, velor lamb or nappalan lamb.

- Various beaver lamb refinements

Refinement

Like all fur skins, the raw sheepskins are made usable for further processing and later use by means of fur finishing. In contrast to leather tanning, the hair remains in the skin. Long-wool skins are partly pre-sheared in the raw state to make dressing easier. The raw shorn wool is also easier to use. The fatty substances are removed from the very fatty sheepskins before tanning. The resulting cavities are typical for this type of fur (double skin), they are smaller in the high-quality pelts of the so-called wool sheep than in the fat sheep with lower coat quality. The matted hair is combed, shorn, ironed, cleaned with wood flour ( "refined" ) and other things, most processes are carried out several times.

While the historically first colors were shades of brown, the chemical products that have now been developed are used to produce practically any desired color nuances. It is possible to dye or print only the leather or only the hair side.

After washing, the sheepskins are shorn to a hair length of 12 to 16 mm. The hair frizz is then permanently removed by repeatedly fixing and ironing, so that even snow and rain do not cause back frizz. The result is a smooth, velvety coat.

Only a small part of the skins supplied is suitable for velor or additional nappalan finishing. The quality of the leather is decisive for its usability; it must be flawless because the leather side is worn on the outside.

Finishing

Compared to most types of fur, processing into clothing or other types of fur does not place any special demands on furriers or industrial workers thanks to the relatively large surface and uniformity of the fur. Compared to other types of fur, the remnants that are comparatively large, are put together into panels and also processed ( → see Remnants of Fur ). In particular, smaller products, such as shoes or footbed sandals, but also larger pattern parts can be cut with appropriately shaped cutting dies.

Hair outside

If the lambskin is worked with the leather facing outwards, it goes without saying that no annoying repair seams or pieces may be made. However, since the seams on the hair side of the beaver lamb are unattractive due to the even height of the cord, such seams should also be avoided as far as possible when processing the hair towards the outside. The fur sewing machine is used for sewing . Putting skins invisibly on top of each other is almost impossible for the furrier with the even hair pattern. If there is a corresponding demand for material for coat lengths, the finisher already takes on this task by assembling the skins as strips of the appropriate length and uniform width before shearing. This is also an advantage for stencil printing, for example for imitations of spotted cats, as the coat drawing can be applied continuously.

Leather outside or reversible

The industrial production of velor and nappa fur, which is mainly carried out in special workshops, requires many complex work steps. The sewing is done with the leather quilting machine, in the manner of processing strong clothing fabrics. The facontal parts of the reversible furs are only rarely put together with the fur sewing machine, the flat seams that are created in the process are possibly covered with tapes.

Hems, edges, receipts, pockets, flaps, belts, bars and in some cases also the seams must be scraped out.

sorts

For the suitability for finishing as beaver lamb, a certain minimum wool fineness and the greatest possible hair thickness are required.

- Bulgarian lambs , a small breed of sheep that provides skins that are correspondingly thin. The attack is very low, in 1981 it was still said that it is often not available for the western market. About 90 percent of the skins are white and 10 percent with black wool. The appearance of the hair appears restless and voluminous, as the wool hair is slightly curled without being particularly swirled or curly. The woolen hair is stable and hard and can be ironed to a light sheen. The leather is soft to medium firm, the velor cut is irregular but medium fine.

- English domestics , English island sheep , provide a large fur. In terms of structure, the goods can be classified as heavy, fur velor quality. The wool is rough and accordingly dull, on the bottom it is strongly matted, it only gets a slight iron-on shine. The leather with a long, compact velor fiber with a somewhat coarse sanding is firm and robust to the touch, it can easily be assessed as "stiff". The rustic fur is particularly warm and extremely hard-wearing, it is used for men's coats and men's jackets. Only small quantities of the young English island sheep, the so-called "spring lambs", are available. Their skin is significantly finer and the wool is not felted.

- Icelandic sheep provide large-area skins with a particularly beautiful, curly coat structure. They are popular as ready-made goods, but only available in limited quantities. The hair pattern can fluctuate a lot within a single coat, that is, strongly curled areas, vertebrae and straight hair are irregularly distributed over the coat. The uniform leather is softer and more supple than that of the English island sheep and the Californian spring lambs; the velor cut is medium to rough. The fur is pleasant to wear and is very hard-wearing.

- California spring lambs are also limited. The pelts are extensive and mostly come from annual animals. This quality belongs to the heavy fur velours, in the trade it can easily be confused with the English domestics. The skins have strong, slightly wavy, but not curly woolen hair, which creates a beautiful, somewhat restless overall structure. The wool is not matted and a little softer than that of the English domestics. The firm and rough leather is less beautiful and therefore results in a rough velor finish, but ensures good wearing properties.

- Spanish entrefinos (hair sheep) are among the best. They supply medium-sized sheepskins that are used for warm men's and women's outerwear. Entrefinos are wool sheep with low fat deposits with the best leather structure. In addition to the soft woolen hair, the pelts, comparable to goat skins, have conspicuous, reinforced guard hairs due to their smooth structure and light hair tips. The hairline goes from the grunt , the middle of the fur, in all directions (to the head, to the back and to the sides), but not the same in all animals. Spanish entrefinos change awns in summer and winter, not wool. The fine leather has a good stand and a certain strength. The pronounced double skin in sheep is only very slight. The leather produces a beautiful, fine velor finish. The wearing properties of the durable fur are very good overall.

- Spanish merinos , also traded as silk lamb, are also used for very high-quality, light and warm clothing, but also for trimmings. Compared to other types of lamb used for fur velours, they have the lowest specific weight . The soft, finest wool takes on the shine very well when ironed on. It is evenly smooth with very slight eddies, the direction of the stroke is uneven. The fine velor cut is not as even as the Entrefino. The very soft and light leather tends to be double-skinned.

- Around 1950, Tescan beaver lamb was the name given to the finishing on shorn of the finest woolen lambskins produced by the English company Clark Son & Morland in Glastonbury.

- Nappalan , a particularly rainproof leather finish . The skins used for this should have a leather structure that is as short as possible. The rough sides of the flesh are primed with various agents to make the leather less absorbent. This is followed by multiple spraying of a polymer such as PVC , polyurethane , a nitro-based paint (sealing) or other. The surface, which has been refined by subsequent pressing, is smooth, slightly shiny. The coating can be loosened again by solvents, so exposed clothing therefore requires special cleaning. Subsequent napping is possible.

trade

Various sheepskins are given fur value by shearing and then dyeing. The lambskins referred to as upper hair are more awny or more woolly; the grander ones are the valuable ones. The best are light and have sleek, silky hair. Lower qualities are stiff, dull in the hair or may have visible repair areas. A significant mistake is curly spots where the hair has not been completely straightened. Worst of all, the double-skinned sheepskin easily ruptures the epidermis , the so-called “ snapping ”, or even the detachment of entire epidermal surfaces. Modern ennobling has largely eradicated these problems. However, the careful selection of the goods suitable for this process remains a condition for a flawless, high-quality result. An English furrier wrote in 1962: “A good beaver lamb coat is almost indestructible, unsurpassed in warmth, easy to maintain and valuable. A less good one has all these qualities to a lesser extent, but a bad one has none of them”.

Similarly refined, but higher-sheared sheepskins are sold under geographical names such as "Toscanalamm" ("Toskaner").

Prepared beaver lambskins are not traded by the number of pieces like other types of fur, but, like all large sheepskins, by square feet.

use

The use of Mouton fur is done to clothing of any kind, to trimmings also to (car) seat covers and other things.

Shorn sheepskins are used in the treatment of bedsores against bedsores . They have a pressure-relieving effect, reduce gravitational forces and have very good moisture dissipation that can prevent skin maceration . Clinical trials are a drop in pressure ulcer cases show when the sheepskins are used in accordance with the Australian Standard 4480 to 1.1998. Since these skins can be washed at up to 95 ° C, hygiene is no longer a problem.

See also

Web links

Individual evidence

- ↑ a b c d e f g h i j k Christian Franke / Johanna Kroll: Jury Fränkel ’s Rauchwaren-Handbuch 1988/89 . 10th revised and expanded edition. Rifra-Verlag, Murrhardt 1988, p. 265-266 .

- ↑ a b Paul Schöps among others: lambskins and sheepskins . In: Das Pelzgewerbe No. 4, 1957, Hermelin-Verlag Dr. Paul Schöps, Berlin, Leipzig, pp. 132-133.

- ^ Mária Kresz: Popular Hungarian furrier work. Budapest 1979, ISBN 963-13-0419-1 I.

- ↑ a b P. Spahl: Beaver lamb and its refinement. In: The fur industry. Issue 2, Berlin, February 1964, pp. 26-29.

- ↑ Without mention of the author: lambskin and lambskin finishing . In: Der Rauchwarenmarkt No. 70, 1935, pp. 2, 5.

- ^ A. Ginzel: The ironing of fur skins . In: Das Pelzgewerbe No. 2, 1967, Hermelin-Verlag Dr. Paul Schöps, Leipzig, p. 74.

- ↑ Alexander Tuma: Pelz-Lexikon. Fur and Rough Goods, Volume XVII . Alexander Tuma, Vienna 1949, p. 84 , keywords “Biberol”, “Biberon”, “Bibus”, “Bibuslamm” .

- ↑ Alexander Tuma: Pelz-Lexikon. Fur and Rough Goods, Volume XVIII . Alexander Tuma, Vienna 1949, p. 43 , keyword “Fokafix” .

- ↑ Author collective: Manufacture of tobacco products and fur clothing . VEB Fachbuchverlag Leipzig 1970, p. 270 → table of contents .

- ^ Anton Ginzel: Characteristics of German fur finishing. In: All about fur. Issue 4, Rhenania Verlag, Koblenz 1974, p. 142.

- ^ A b Elisabeth Ewing: Fur in Dress. BT Batsford, London 1961, ISBN 0-7134-1741-2 , pp. 132-133 (English).

- ↑ a b Author collective: Der Kürschner. Technical and textbook for the furrier trade. 2nd revised edition. Vocational training committee of the central association of the furrier trade (ed.), JP Bachem publishing house, Cologne 1956, p. 103. → Book cover and table of contents .

- ↑ a b c d e f g h i j k l Sonja Langer-Korsch: Leather clothing on sale. Reference book for leather clothing. Association of the German Leather Clothing Industry, Munich November 1981, pp. 49, 51, 63, 67, 75, 109, 135.

- ↑ Roland Dittrich: It was like that . Self-published, Kleineibstadt, approx. 1998/1999, p. 187.

- ↑ Alexander Tuma: Pelz-Lexikon. Fur and Rough Goods, Volume XXI . Alexander Tuma, Vienna 1951, p. 200 , keyword "Tescan beaver lamb" .

- ↑ Alfons Hofer: Textile and Model Lexicon. 7th edition. Volume 1, Deutscher Fachverlag, Frankfurt am Main 1997, ISBN 3-87150-518-8 , p. 601, keyword “Nappalan”.

- ↑ JG Links: How to look at Furs . The Bodley Head, for private distribution by Calman Links, London 1962, pp. 106-109.

- ↑ www.fellcastell.de: FAQ .