Photo sedimentation

The photosedimentation is one of the most important methods of particle size analysis . This technique determines the size of particles by measuring the speed at which the particles sink to the bottom of a vessel ( sedimentation speed ). This is done by continuously measuring the absorbance of the sample.

functionality

In general, photosedimentation can be described as a photometric measurement of the sedimentation velocity of particles. In order to carry out these measurements, a dispersion of the sample to be examined and a liquid, also called a dispersion medium , is first prepared. When choosing the dispersant, it is particularly important to ensure that it has a lower density than the particles to be examined, so that the particles can sink downwards as part of sedimentation . It is also important that the particles must not react with the dispersant and that the dispersant flows around them in a laminar manner.

The dispersion is stirred until it can be assumed that the particles are homogeneously distributed. The sedimentation speed of the particles can be measured on the basis of this homogeneity. Depending on the particle size, different methods are used for sedimentation:

- If the particles are larger than 5 μm, the sedimentation is triggered by the force of gravity . For this purpose, the previously prepared dispersion is left to rest and the particles begin to sink due to the force of gravity. The largest particles sediment the fastest and the smallest particles the slowest.

- If, on the other hand, the particles are smaller than 5 μm, the sedimentation, triggered by the gravitational force, would last so long that it would be influenced by the Brownian movement . For this reason, the action of centrifugal force accelerates the sedimentation . In order to obtain good measurement results, the previously prepared sample dispersion should be filled into a cell of the centrifuge with a liquid using a layering process.

- This layering carries the risk of convection currents . For this reason, there should also be a density gradient in the liquid .

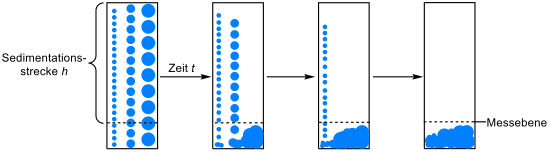

With the onset of sedimentation, the photometric measurement starts . For this purpose, the sample is irradiated in a certain area (called the measuring area or measuring plane) and the transmission or extinction is measured. These quantities are dependent on the concentration of the particles, because the radiation is weakened by absorption, refraction and scattering phenomena of the particles in the sample. If the particle concentration is high, the extinction is also high because the radiation is greatly attenuated.

In order to be able to make statements about the sedimentation speed of the particles and thus also about their size, the extinction is measured as a function of time. For this purpose, it is determined in the measuring plane when the extinction changes. Since the largest particles have the highest sedimentation speed, they are the first to leave the measuring plane, so that the extinction decreases at this point in time. The extinction drops again as soon as the particles, which are somewhat smaller, have left the measuring plane, etc. Using mathematical formulas, a statement can be made about the size of the particles via the extinction. This is discussed in more detail in the Mathematical Background section .

Schematic structure of a photo sedimentation device

Photo sedimentation is carried out using a photo sedimentation device. According to the description in the section Functionality, there are devices in which the sedimentation takes place in a centrifuge or those in which the sedimentation takes place only through gravity.

In the devices in which sedimentation only takes place in the gravitational field, a radiation source ( 1 ) irradiates the sample dispersion in the sample cell ( 3 ) at the level of the measuring plane. A screen ( 2 ) is built in front of the sample cell so that only this plane is hit . The transmitted radiation arrives at the sample photodetector ( 4 ) and from there it is passed via the signal processor ( 5 ) to the computer ( 6 ) and processed. The reference photodetector ( 7 ) also measures radiation from the light source.

If the sedimentation is accelerated by a centrifuge, the structure looks a little different: The centrifuge ( 2 ), which is filled with a sample cell ( 3 ) and a reference cell ( 4 ), is driven by a motor ( 1 ) . These cells are irradiated with the light sources ( 5 and 6 ), the transmitted radiation from the sample cell striking the detector ( 7 ) and from the reference cell striking the detector ( 8 ). These signals are sent to the computer ( 10 ) via the signal processor ( 9 ) . There they are finally processed. The speed of the centrifuge is regulated by the computer via the control point ( 11 ).

application

Photo sedimentation is generally used in quality assurance . It is used to increase the size of z. B. Polymers and dyes or particles in drugs to determine. One possible area of application for the method presented is in the pharmaceutical industry . Here, for example, asthma sprays are produced, which release the active ingredient in the form of tiny particles directly into the lungs. Because of this direct release it is important to control the particle size, which can be done with the help of photosedimentation.

Math background

In order to understand the measuring principle of a photosedimentation device, the relationship between the sedimentation speed and the particle size and the relationship between the extinction and the particle size must be clarified.

Relationship between the sedimentation speed and the particle size

The easiest way to perform calculations is for particles that are round like a sphere. However, since it cannot be assumed that the particles to be examined are shaped like a sphere, the equivalent diameter of a sphere is assigned to them. This means that a particle is equated with a sphere with a certain diameter , which consists of the same material and has the same sedimentation speed.

Since above all very small particles are examined and because the particles are to have a laminar flow around the particles, this diameter can be determined using Stokes' law. This equivalent diameter of the particles is called the Stokes diameter and represents the diameter as a function of the speed.

For sedimentation by gravity, the Stokes diameter is calculated as follows:

- stands for the viscosity of the dispersant, for the density of the particle, for the density of the dispersant, for the acceleration due to gravity and for the sedimentation speed , which is composed of the sedimentation distance and time .

For the sedimentation in the centrifuge, the formula for the Stokes diameter is:

- stands for the rotation speed, for the radius of the measuring plane and for the starting point radius .

| Derivation of the Stokes diameter | ||||||||||||||||||||||||||||||

| A particle is considered that is in the dispersant. On this particle act u. a. a force like the force of gravity that makes it sink and a force of lift . If, for example, the force of gravity is greater, the particle sinks and is accelerated in the process. Because the speed increases more and more, the frictional force that acts on the particle also increases more and more. As a result, the acceleration that the particle experiences becomes less and less so that it finally moves at a constant speed. It is then:

These forces can also be described as follows:

So this is:

If these two equations are used, the following results are obtained: After changing over, is: If this is changed over according to the diameter , the Stokes diameter is obtained :As in the chapter on the operation has been described and is shown in the inset image there, the measured level is set so that the distance from the starting point as sedimentation to the measurement plane can be described. Since the measurement takes place as a function of time, it can be determined in what time the sedimentation path was covered. The sedimentation speed is therefore:

For the Stokes diameter, this results in:

The formula for calculating the Stokes diameter in the gravitational field has thus been derived.

The sedimentation of particles smaller than 5 μm is accelerated by a centrifuge. The centrifugal acceleration acts in this , which is why the following applies to the Stokes diameter :

In a centrifuge, the sedimentation speed of the particle results from the time it takes for the particle to get from the starting point radius to the measuring radius . So it is:

This gives the Stokes diameter of a particle in the centrifuge: |

Relationship between the absorbance and the diameter of the particles

The particles are so small that it is difficult to determine the sedimentation speed for individual particle sizes. For this reason, a further reference value must be used which is dependent on the particle size and which can be determined more easily: This is the extinction of the solution, which is measured with a constant sedimentation distance as a function of time.

For the extinction of the measurement in the gravitational field, the sedimentation path is the height of the measuring plane , as can be seen in the picture in the section on Functionality . The following applies:

For the extinction of the measurement in the centrifugal field, the sedimentation distance is the difference between the radius of the measuring plane and the radius of the starting area and the following applies:

- Here stands for the form factor , for the concentration of the particles or for the sedimentation path , for the absorption coefficient of the particles with the diameter and for the number of particles with the diameter in the measuring plane. Note that the diameter is currently the Stokes diameter .

- Here stands for the form factor , for the concentration of the particles or for the sedimentation path , for the absorption coefficient of the particles with the diameter and for the number of particles with the diameter in the measuring plane. Note that the diameter is currently the Stokes diameter .

If there is now in the period and the change in absorbance , then there are particles with the average Stokes diameter in the measuring plane.

The following applies to measurements in the gravitational field:

The following applies to measurements in the centrifuge:

With the help of this equation, it is possible to use mathematical methods to calculate the average diameter of the particles that are in the measuring plane during the time of the change in absorption. To do this, however, it must be known how the absorption coefficient changes with changing particle size. If this is not the case, a reference sample is used for calibration.

Individual evidence

- ↑ a b c d e f g h i j k l m n o p q r s t u v w x y z aa ab D. A. Skoog, FJ Holler, SR Crouch: Instrumentelle Analytics. 6th edition. Springer-Verlag , Berlin / Heidelberg 2013, ISBN 978-3-642-38169-0 , pp. 931-934.

- ↑ RO Gumprecht, CM Sliepcevich: Measurement of Particle Sizes in Polydispersed Systems by Means of Light Transmission Measurements Combined with differential settling. In: The Journal of Physical Chemistry . Volume 57, No. 1, 1953, pp. 95-97, doi: 10.1021 / j150502a020 .

- ↑ a b K. Leschonski: Characterization of disperse systems, particle size analysis. In: Chemical Engineer Technology . Volume 45, No. 1, 1973, pp. 8-18, doi: 10.1002 / cite.330450103 .

- ↑ a b c d e M. Stieß: Mechanical process engineering - Particle technology 1. 3. Edition. Springer Verlag , Berlin / Heidelberg 2009, ISBN 978-3-540-32551-2 .

- ↑ B. Koglin, K. Leschonski, W. Alex: Particle Size Analysis - 5. Sedimentation Analysis. In: Chemical Engineer Technology . Volume 46, No. 13, 1974, pp. 563-566, doi: 10.1002 / cite.330461307 .

- ↑ a b S. Will, K. Kraft, A. Reith, A. Leipertz: Grain size analysis in process measurement technology on photosedimentation. In: Chemical Engineer Technology . Volume 67, No. 1, 1995, pp. 113-117, doi: 10.1002 / cite.330670118 .