Point density

In image reproduction, the point density is a measure of the level of detail in a rasterized visual representation and thus one of the quality aspects of the technical reproduction process. Point densities are specified , for example, in four-color printing or in a screen display .

Common units of point density in practice are:

- dpi

- dots per inch, English for "points per inch ",

- dpcm or dpc

- dots per centimeter / centimeter, English for "points per centimeter ",

- ppi

- pixels per inch, English for " pixels per inch",

- ppcm or px / cm

- Pixels per centimeter.

- ppmm

- Pixels per millimeter.

- spi

- samples per inch, English for " samples per inch" (e.g. scanner ),

- lpi

- lines per inch, English for "lines per inch",

- L / cm

- Lines per centimeter.

One also speaks of point density in the case of a rastered image scanning , for example by means of a scanner . Here, too, it is one of the quality aspects of the scanning process.

For the quality "perceived" by the human eye ( visual perception ), in addition to the point density, other factors play a decisive role, including the depth of color and the sharpness of the original itself.

Conceptual differentiations

classification

The differentiation of point density into different units that is common today has historical causes. The universality of digital images and their diffusion in the mass market did not begin until the 1990s. Until then, image processing was located in various areas:

Each area used and continues to use its own terminology and units of measurement. There are often technical compatibility problems between these areas (see also “ Current developments in image processing ”), and attention must always be paid to the techniques and effects of the current reproduction. In addition, there are purely arithmetical differences due to the use of both the Anglo-American measurement system and the metric system .

resolution

Colloquially in all of the above Often only the variant-rich term "resolution" is used in areas. In each individual case, however, a distinction must be made as to whether they are, for example, pressure points, pixels , a number of rows or columns, a total number of pixels, or a purely arithmetic variable (for example by means of interpolation ).

The sometimes used term "relative resolution" is misleading because the point density is an absolute physical quantity and can be measured directly.

Point

When specifying a point density, it must be clear from the context what is meant by a point in the individual case. This can mean, among other things:

- a (any color) pixel of a template (for example a graphic file)

- a (any color) pixel of a reproduction (for example an RGB pixel of an LCD )

- a single-colored point when rendering ( e.g. dot , subpixel )

- Any colored printing point from a special reproduction process, for example thermal sublimation printing

- a monochrome scanning point of an optical sensor

- any colored scanning point of a sensor system

The distinction is important because, for example, with common printing processes, several printing points fall on one pixel and the subdivision has a direct effect on the ratio of points per length . In terms of subpixels, a computer screen has three times the resolution horizontally as vertically. The division of the pixels into differently colored display points occurs in many imaging processes , for example in four-color printing, but also in a normal screen . There the terms subpixel , segment or sample are also used for the monochrome display points .

Point density

The point density is based on the following definitions:

- 1 dpi = 1 point per inch

with 1 inch = 25.4 mm. Converted, this results in 0.3937 points per cm

- 1 point per cm = 2.54 dpi (logical conversion)

This unit is also known as dpc for dots per centimeter / centimeter .

example 1

In the given example of the fish graphic on the right, the following point densities result for the yellow and blue "points" on the screen:

- horizontal: 24 pixels per length a (240 pixels)

- vertical: 20 pixels per length b (200 pixels)

(11 ppi each on a screen with 110 dpi)

In today's computer monitors and graphics with square pixels, horizontal and vertical point densities are identical.

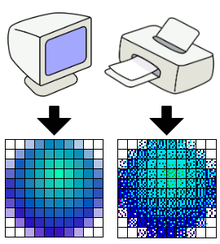

The point density of the graphic can be determined from the point density of the display screen (according to its technical data, e.g. 96 ppi) or the printout of a printer. The graphic itself (as a computer graphic file) has no resolution in dpi or ppi, as it exists independently of the display medium.

Example 2

A resolution of 1200 dpi horizontally and 600 dpi vertically corresponds to a point size of 21.2 µm × 42.3 µm (assuming that the dots are seamless and flat). "1200 dpi horizontal" means that 1200 points are distributed horizontally over 25.4 mm. Accordingly, a point in the horizontal has an edge length of

- 25.4 mm ÷ 1200 = 0.0212 mm = 21.2 µm.

Since the vertical resolution is only 600 dpi, a point is twice as “long”, namely

- 25.4 mm ÷ 600 = 0.0423 mm = 42.3 µm.

For a single such point there is a total area of

- 21.2 µm x 42.3 µm = 897 µm².

Applications

Below are some common methods in which screening plays an important role (table Typical point densities ).

Four color printing

For four-color printing , each pixel is broken down into dots of the four process colors ( CMYK ) according to its color . The more finely the halftone printing screens are resolved (dot density), the better these printing dots mix as a result for the human eye.

| application | Point density |

|---|---|

|

Daily newspaper , 1993 ( width of the halftone screen) |

75-85 lpi |

| Modern daily newspaper (width of the halftone grid) |

150 lpi |

| Laser printer | 1200 dpi |

| Inkjet printer | 1200 dpi |

| Photo exposure | 300 ppi |

| Dye sublimation printer | 300 to 400 ppi |

| Flatbed scanner | 1200 ppi |

|

35mm film (approximate equivalent between film grain and assumed raster) |

2000-10,000 ppi |

| High quality film scanner | 4800 ppi |

| Slide exposure 4K / 8K (for 35mm slides) |

2900/5800 ppi |

|

Computer mouse (density of detectable individual steps) |

400 to 16,000 dpi |

Exposure on photo paper

There is no visible print raster when exposed on photo-chemical paper . The maximum achievable reproduction quality is determined by the optical exposure process and the chemical and physical properties of the paper (e.g. grain size, surface quality).

scanner

As a rule, scanners capture an original according to a grid process, line by line and point by point. From the history, the scanning density is given in pixels per inch (dpi) , since it was previously used almost exclusively in prepress and for later printing. Today, scans are usually related to pixels, so that the unit “ppi” is also used.

See also: fax

Digital camera

The level of detail in digitally recorded photos is usually indicated by the total number of pixels recorded by the sensor (“image size” of the sensor in megapixels ).

It should be noted that other (optical and electrical) components in the camera also significantly determine and limit the achievable image quality.

screen

In the case of screens , the following values are essentially important for the level of detail in reproduction:

- the number of pixels in the horizontal and vertical direction, in each case in pixels

- the edge length of this visible image area in cm or inches

This results in a point density (reproduction resolution) in pixels per inch (ppi) for the horizontal and vertical lines:

- is the number of image points in the diagonal direction in pixels,

- is the number of image points in the horizontal direction in pixels,

- is the number of image points in the vertical direction in pixels and

- is the diagonal length of the visible image area in inches. (Screen size in inches, for example 22 ".)

In practice, the devices differ in both classifications. In particular, the often mentioned value of “72 ppi” (for “RGB pixels”) does not apply to all devices.

Examples:

- A 20-inch screen (50.8 cm diagonal) with 1680 × 1050 pixels has 99.06 ppi.

- A 10.1-inch netbook screen (25.65 cm diagonal) with 1024 × 600 pixels has 118 ppi.

- A 9.7-inch (24.6 cm diagonal) screen with 2048 × 1536 has 264 ppi.

- A 4.8-inch (12.2 cm diagonal) screen with 1280 × 720 has 306 ppi.

- A 3.5-inch (8.9 cm diagonal) screen with 960 × 640 has 329.65 ppi.

computer mouse

In the case of computer mice , the number of detectable smallest individual steps per unit of length is given to indicate guidance accuracy. The usual unit for this is dpi, cpi ("counts per inch") or ppi ("pulses per inch"), as it relates to steps and not to pressure points.

Graphics file

The reproduction quality in the sense of the richness of detail of raster graphic files (for example in JPEG or PNG format) essentially depends on the reproduction method and the image size of the graphic in (mega) pixels.

The graphic data itself has no inherent quality-determining point density. However, a point density (pixel density) can be specified in the metadata (e.g. EXIF entries ) which - together with the dimensions in pixels - represents physical dimensions (e.g. desired output dimensions or actual original dimensions). Examples: The graphic data of a photo is 1800 × 1200 pixels, the metadata is 300 pixels per inch; this gives a physical size of 6 "x 4" (approximately 15 cm x 10 cm). An original with 8 "× 12" (very roughly A4 format ) takes up an area of 4800 × 7200 pixels in the output file of a scanning program, because the scanner scanned with 600 dpi; The 600 in the metadata can be used to infer the original dimensions of the scanned original.

It should be noted that more or less meaningful default values are often stored in the metadata. When editing, it should also be noted that what is meant by size 100% depends on the software at hand . One meaning is that a pixel of the graphic data is mapped onto a pixel on the monitor (typically in graphic programs); the values from the metadata are not taken into account. Another is that scaling takes place on the basis of the metadata, so that the physical format on the output medium is aimed for (for example, in the case of photos in texts in word processing).

In addition to graphic files with a pixel grid, there are also graphic files without a pixel grid: the vector graphics . Depending on the file format , pixels appear as a unit of measurement for coordinates . However, since decimal numbers can appear as coordinate values , this is not the basis for a grid.

Point density transformation

In order to adapt a screened template to a screened reproduction process, the output data must be transformed (scaled). The following cases are possible:

- Implementation 1: 1 , i.e. that is, the size of the original (in pixels) is exactly the same as the output. Example: simple matrix display

- Downsizing , d. that is, the size of the original (in pixels) is larger than the output. Example: 5 MP JPG file displayed on the camera's LCD

- Magnification , d. that is, the size of the original (in pixels) is smaller than the output. Example: 1 MP photo displayed on an LC screen with a size of 1600 × 1200 pixels (1.9 MP)

The implementation almost always takes place by means of interpolation to calculate pixels that were originally not available. Compare also sharpness / interpolation .

See also

Web links

- Dot density , digital imaging , Wikibook

- dot / meter [dot / m] <—> dot / inch [dpi] , Kateryna Yuri, English online converter

source

- ↑ Mattias Nyman: Four Colors / One Image - Getting Great Color Output with Photoshop, QuarkXPress, and Cachet. Peachpit Press, Berkeley, California 1993, ISBN 1-56609-083-0 , p. 5, "Recommended screen frequencies for offset printing; suitable for newspaper, board ".