Tension optics

As photoelasticity a branch is optics or the Konstruktionslehre referred to in which, through the use of polarized light, the voltage distribution is examined in light-transmitting bodies. When exposed to mechanical stress, areas of particularly high stress become visible on transparent, two-dimensional workpiece models. The basis is the property of many optically isotropic materials to become birefringent under mechanical stress . As a result, the plane of polarization of incident light is rotated or elliptically or circularly polarized light is produced. This can be made visible with a polarimeter .

The use of monochromatic light creates a system of dark and light stripes, the arrangement of which allows reliable conclusions to be drawn about the distribution and size of the mechanical stress at all points on the body.

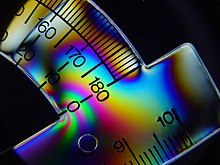

In the picture on the right, two types of dark stripes are created on a test body loaded by forces : the isochromatic lines are lines with a constant main stress difference, on the isoclines the direction of a main stress coincides with the polarization direction of the incident light, they thus represent the stress trajectories of the body below the given load.

To distinguish between isochromats and isoclines, the loaded sample (or the direction of polarization of the light) can be rotated - this changes the isoclines in the stress-optical image, but not the isochromates. Another possibility is to use circularly polarized light - in this case no isoclines are visible (lower two images).

If white light is used, different light-dark patterns are created for each color - this results in the color pattern as shown in the picture on the left. Only in the 0th order of the stripes do all the colors coincide. This results in black stripes at the unloaded areas in the sample (lower corner of the angle).

The quantitative evaluation is based on a level state of stress. The two principal stresses in the specimen plane influence the refractive index of the material, the third principal stress in the direction of the thickness has no effect.

This method is still occasionally used in materials testing by examining transparent synthetic resin models (with optical activity ) for loads that can occur in practical use. The stress distribution in the model matches that in the real component, even if the deformation is different.

Thanks to the improved computation methods with the finite element method , these investigations are now mainly carried out on the computer.

Web links

- Video: tension optics . Institute for Scientific Film (IWF) 1949, made available by the Technical Information Library (TIB), doi : 10.3203 / IWF / C-558 .

Individual evidence

- ↑ Andreas Reichert, Henning Katte: Basics of tension optics. ilis GmbH, Erlangen 2005 (PDF file; 262 kB).