Knitting machine

A knitting machine is used for mechanical and automated knitting . A distinction is made between flat knitting machines and circular knitting machines.

Flat knitting machine

The first hand-operated flat knitting machine was in 1863 by Isaac William Lamb used in America. This enabled the quick production of tubular and right / right knitwear. Due to the great transverse elasticity, right / right goods can be stretched up to 100%. In 1864 the machine was further developed by Henry J. Griswold and used to manufacture men's socks and children's socks. A further improvement made possible the reduction of the stockings as well as the production of ribbed structures and circular knitted stockings. In 1867 Henri Edouard Dubied acquired the patent and began building knitting machines. At the same time it was started in Germany and France ( Laue and Timaeus ). With the double latch needle from Durand it was possible from 1881 to produce left / left goods. With the invention of the hose lock (method for heel formation) in 1888 by G. F. Grosser , Chemnitz-Markersdorf (1871–1948), from then on it was possible to produce complete stockings and socks on one machine.

With the introduction of the electric motor, it became possible for smaller companies to use machines that worked efficiently.

Motorized flat knitting machines became important at the beginning of 1880. Initially, these machines were semi-automatic . Work steps such as expanding or reducing had to be carried out by hand. It was not until 1910 that automatic length machines replaced the hand-operated flat knitting machines. However, the stocking foot first had to be produced on footing machines and then knitted onto the prefabricated stocking lengths using the circular knitting process. In part, this manufacturing process for the “standard stockings”, i.e. flat-knitted stockings with separately knitted feet, remained in place until the 1970s.

Circular knitting machine

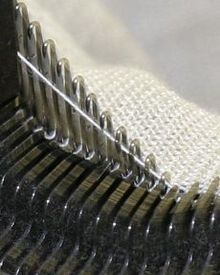

In circular knitting machines , the loop-forming elements (needles and sinkers) are arranged in a circle. An essential distinguishing feature is the number of fountains (needle beds, tracks on which the needles move), a distinction is made between single- fountain ( single jersey ) and double-fountain ( double jersey ) machines. Single jersey is knitted right / left, double jersey is knitted left / left or right / right. In addition, the diameter (usually specified in inches ) and fineness (usually needles per inch, also specified in "E" [1E = one needle per inch]) of the machines play an important role.

In circular machine knitting, a knitting yarn is inserted into the latch needles , the needle is closed and the thread is pulled through the stitch that was already on the needle. Now the needle is opened again and pushed upwards, driven out. The sinkers, which are arranged between the needles, have to be imagined as lying Us. Your job is to keep the finished stitches horizontally at the same height. The knitted fabric comes to lie inside a us and is knitted (stitched to the desired size) before it is pulled off and wound up in the lower part of the circular knitting machine. The needles move vertically in a circle when knitting.

In contrast to circular knitting by hand, machine circular knitting allows several threads to be knitted at the same time. The process of stitch formation described above is repeated several times with several threads on the needle circle, so that several lines are formed per revolution of the needle. As a result, today's circular knitting machines achieve outputs of several tens of kg / h.

This knitted fabric is called tubular fabric, as the fabric produced leaves the machine as a long hose. T-shirts and pullovers are made from tubular fabric, the production of which is cheaper because there are no side seams. Accordingly, products made from tubular fabric can be recognized by the missing side seam.

Supplier

In machine knitting it is important that the tension of the yarn is as constant as possible. The function of the left little finger when knitting by hand has to be replaced by a sophisticated device, called a supplier (French: supplier ). The feeders are attached just before the knitting systems of the knitting machine. They are used in flat knitting machines, circular knitting machines, stocking machines and also in weaving machines (only for the weft threads).

History, production

Traditionally, English inventors and manufacturers played an essential role in the development of the first circular knitting machines.

The technical perfection of the machines and the industrial maturation was mainly done by French and German engineers and entrepreneurs. Today the German machine manufacturers Mayer & Cie and Terrot dominate the world market for circular knitting machines. However, they are increasingly being used by competitors and imitators from the Far East, especially Taiwan , the People's Republic of China and z. Partly also copied Korea .

The market for the core items of the circular knitting machines, especially latch needles and corresponding sinkers, is dominated by German companies. There are films from the GDR that show that Heinrich Mauersberger was the inventor of new circular knitting processes in the GDR.

Home knitting machine

For home and hobby knitters, there had been a number of small mechanical knitting machines since the 1950s, and electrical and later computer-controlled home knitting machines were offered since the 1970s. Compared to hand knitting, these offer the advantage of being able to produce large, simply patterned parts in a shorter time. However, home knitters are only suitable to a limited extent for commercial use, as handling is not easy to learn, and the rest of the work on a piece of knitting, adapting, sewing together, sewing the threads, unlike in industrial production, still has to be done by hand. Depending on the thickness of the yarn, a distinction is made between coarse, medium, fine and super fine knitters with a number of needles from 180 to 240. For pattern knitting, some of the models have a mechanical punch card control; newer models are electronically controlled. An embedding knitter only creates right stitches or patterns based on right stitches; with a double bed, left stitches or right-left patterns can also be created. Furthermore, the double bed also allows circular knitting, e.g. B. for socks.

See also

Individual evidence

- ↑ US Patent # 50,369 Isaac W. Lamb from Rochester (New York) ( New York ), (October 10, 1865), and # 39,934 (September 15, 1863)