Archtop

Archtop (also Arched Top ; English for "vaulted ceiling") is a technical term from musical instrument construction for a special form of construction of guitars and mandolins . On the one hand, it describes the outwardly vaulted ceilings of the instruments, which are made using various methods, and on the other, as a generic term for these instruments themselves. This type of construction was adopted from violin making towards the end of the 19th century . Archtop guitars are often colloquially referred to as "jazz guitars"; In the German-speaking area, the term "strike guitar" is also common.

history

The archtop construction principle for string instruments goes back to a development by master violin makers in the 16th and 17th centuries. They carved the top, back and sides from solid wood; Spruce wood was mostly used for the top and maple wood for the sides and back .

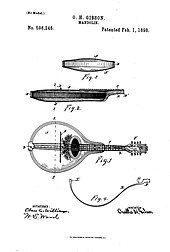

The development of archtop guitars and mandolins is attributed to the American instrument maker Orville H. Gibson (1856–1918), namesake of the musical instrument manufacturer Gibson Guitar Corporation . In the 1890s, Gibson transferred the construction forms from traditional violin making to mandolins and acoustic guitars for the first time in his workshop in Kalamazoo , Michigan . Gibson intended to improve the sound of the instruments and to increase their volume. The first archtop instruments of Gibson usually had a round or elliptical shaped sound hole that just before the end of the fingerboard was placed centrally in the vaulted ceiling. On February 1, 1898, Orville Gibson was granted a US patent for this design. In order not to hinder the vibration properties of the top and thus the sound of the instruments, from 1908 onwards they were fitted with a pickguard that was clamped to the frame and floating freely above the top and a tailpiece that was also only attached to the frame .

The construction of archtop instruments at Gibson was significantly further developed when the mandolin virtuoso, composer and violin maker Lloyd Loar joined the company as chief engineer in 1919 . By 1923 he had developed a number of archtop mandolin and guitar models that were more based on violin making than before. The most striking feature of Loar's development work are the f- shape sound holes built into the ceiling ; a design element that should be typical for archtop instruments. The flagship of Lloyd Loars model line was the Gibson L-5 guitar ; an instrument that in later years was often considered the most typical archtop guitar model. Other manufacturers such as Epiphone and CF Martin adopted the design features introduced by Gibson since the 1930s with varying degrees of economic success.

The first industrially mass-produced electric guitar was the Gibson ES-150 archtop model . This model, first presented in 1936, which outwardly resembles the acoustic archtop guitars known until then, was the first to have an electromagnetic pickup together with control buttons mounted directly on the vaulted ceiling. In the following years Gibson developed several other archtop guitars in its ES (Electro-Spanish) range , such as the ES-175 and Byrdland models .

The archtop guitar underwent further development in the late 20th century when guitar makers like D'Aquisto began to modify the traditional designs of the instrument. The vaulted top was retained with other basic design features, but these manufacturers experimented with other body and cutaway shapes, with the shape and location of the sound holes, and with alternative forms of electrical reinforcement.

The manufacture of vaulted ceilings and floors

The production of instrument ceilings and floors from wood requires extensive knowledge and skills in the specialist field of the carpentry trade . For the production of vaulted wooden ceilings and floors for archtop instruments, there are two processes that differ significantly in terms of manufacturing effort and requirements:

Manufacture from solid wood

In the traditional artisanal production method, the ceiling and floor are carved out of solid, grown wood. A sufficiently thick, straight and evenly grown tree trunk (mostly spruce or maple) serves as the basis for these instrument components. This is first stripped of bark and sawed into individual pieces about 50 centimeters long. The individual pieces of the tree trunk are then split lengthways into narrow, wedge-shaped segments of the same size . After these wooden wedges have been left to dry for a long time in the air, two wedges with a grain that is as similar as possible are glued together on their straightened narrow sides (English: bookmatched ). The resulting workpiece , which is rectangular in outline, has the shape of an obtuse , isosceles triangle in profile . The upper edge of the assembled wedges marks the vertical center line of the later instrument ceiling or the floor from the lower edge of the body to the base of the neck. This flat workpiece is sawn into the shape of the body outline of the musical instrument to be built. This is followed by the most complex work step, the working out of the actual curvature. This is done by evenly carving and planing the workpiece by hand or using milling machines that are computer-controlled in modern companies ( CNC machines ). Due to the high cost of manufacturing and materials, archtop instruments with top and back made of solid wood are among the highest quality and therefore also most expensive of their kind. An example of an archtop guitar made in this way is the Gibson Super 400 introduced in 1934 .

Manufacture from plywood

A more recent method than carving or milling out of solid wood is machine pressing thin wooden panels into the curved shape. Initially, guitar makers used solid wood panels for this; a difficult process as there is always the risk of cracks forming in the wood. Therefore, this method was not widely used. Since around the end of the 1940s, instead of solid wood, plywood , a laminate made of three to five thin layers of wood, has been used for pressing archtop components . The risk of cracking during production and the consumption of materials were minimized, so that musical instruments with components made in this way can be offered at significantly lower prices than instruments with solid wood parts. One of the first guitar models with a curved plywood top and back to find widespread use was the Gibson ES-175 archtop electric guitar introduced in 1948 .

Archtop instrument maker

Important manufacturers of archtop instruments are the US company Gibson (mandolins, acoustic guitars and electric guitars) and (only guitars) the US companies Epiphone , Stromberg, D'Angelico, Gretsch and Guild . In Germany the companies Höfner , Hoyer , Framus and Roger are among the best-known, a prominent manufacturer from Asia is the Ibanez company . In addition, there are a large number of manufacturers who produce archtop musical instruments in small companies or as independent guitar makers; Such instruments are usually only available in very small editions or are made as individual pieces.

literature

- Hans Korseck : school for plectrum guitar . Zimmermann music publisher, 1941

- Tony Bacon, Dave Hunter: Totally Guitar - the Definitive Guide ,

Guitar Encyclopedia. Backbeat Books, London 2004. ISBN 1-871547-81-4 - Carlo May: Vintage guitars and their stories. MM-Musik-Media-Verlag, Augsburg 1994. ISBN 3-927954-10-1

- Alexander Schmitz: The guitar. Ellert & Richter Verlag, 1988

Web links

- Archtop Germany , specialist website for archtop guitars made in Germany (accessed on March 10, 2012)

- Fernando Alonso Jaen: The Archtop Jazz Guitar , article on the history of archtop guitars (accessed March 2, 2011)

- Photos and descriptions of Orville Gibson's earliest archtop guitars and mandolins (accessed March 3, 2011)

Individual evidence

- ↑ Alexander Schmitz: The guitar , p. 101

- ↑ Made By Hand: The Story of Gibson Acoustic ( Memento of the original from March 7, 2011 in the Internet Archive ) Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice. on gibson.com (English)

- ^ Carlo May: Vintage guitars and their stories. P. 33 f.

- ^ Carlo May: Vintage guitars and their stories. P. 35

- ↑ Alexander Schmitz: The guitar , p. 105

- ↑ Bacon / Hunter: Totally Guitar , p. 22 f.

- ↑ Helmuth Lemme: Elektro-Guitar-Sound, p. 14. Pflaum Verlag, Munich 1994. ISBN 3-7905-0675-3

- ↑ Helmuth Lemme: Elektro-Guitar-Sound, p. 15

- ↑ Bacon / Hunter: Totally Guitar , pp. 20 ff.