Planer

The slicer is a tool for the machining of wood . The surface of the wood is processed by removing chips from the material with a plane iron or knife . The aim is to smooth or dress the surface.

Classic hand planes have a fixed cutting edge that is fixed in the plane body. In the case of electric planing, a knife shaft rotates with inserted cutting edges.

construction

Although hand planes differ greatly in their construction, some elements can be found in all variants:

- The bottom of the plane body (the plane sole) rests on the workpiece. It has a holder for the plane iron and devices that make it easier to guide the plane. The chip passage through which the knife reaches down to the workpiece is located in the planer sole. At the same time, the chips that are produced are discharged upwards through the chip passage.

Since the plane body is symmetrical, a simple plane can in principle be used equally well by right- or left-handers. However, the front handle is often designed asymmetrically. - The plane iron is made of tool steel and ensures the removal of material as well as the discharge of chips upwards through the so-called plane jaw.

- The clamping device ensures that the plane iron is reliably fixed.

In addition to the sharpness of the iron, the cutting performance and surface quality also depend on the cutting angle , i.e. the angle by which the chip is deflected upwards. Since this angle cannot be changed, there are planes with different cutting angles for different applications: the steeper the blade, the smoother the surface will be, but the effort required for the cut increases.

While all planes were originally made of wood, plane bodies made of cast iron came up during industrialization in England. The complex adjustment devices of the metal planes differ in their functionality from those of the wooden planes and allow the finest adjustments by means of a screw.

Structure of the wooden planer

The plane nose is located at the front of the box. It is used to guide the tool with the first hand. The other hand grasps the handguard behind the clamping wedge. It carries out the pushing movement. The strike button is attached to the back of the planer box. By tapping this metal button lightly with the hammer, the plane iron is withdrawn during adjustment and the chip thickness is reduced. In addition, the wedge and iron can be completely loosened and removed when the plane iron is to be sharpened.

The plane sole, which is heavily stressed during planing, often consists of a glued-on, particularly resistant wood, such as hornbeam or pockwood (guaiac).

A slightly different design can be found in the Japanese plane, the Kanna , which is not pushed over the workpiece, but rather pulled.

Structure of the metal plane

While there are many different designs for metal planes, they are all constructed in a similar way to the following two types.

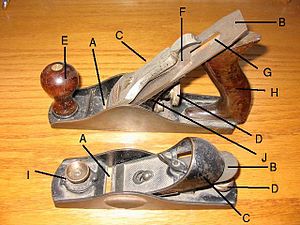

Bench planes usually have an ergonomic handle (H) at the back and a smaller knob (E) at the front for comfortable two-handed guidance. A lever for lateral adjustment of the plane iron and a wheel (D) for adjusting the chip thickness are close by. The plane iron (B) sits on the frog (J). This ensures the correct cutting angle. It can also be moved back and forth so that the size of the planer mouth (A) can be adjusted. The plane iron is fixed via the flap (C).

Block planes are designed as one-hand planes (with the iron bevel on top) and therefore have no handle and no frog. With them, the planer mouth (A) can be opened and closed by a movable part of the planer sole located at the front - fixed by the finger button (I).

Hand planer (electric planer)

Hand planers have one of a plane body in the electric motor -driven shaft mounted in the one or more exchangeable blade are stretched. The shaft can be mounted on one side so that folds can be created or reworked at any depth. The front part of the planer sole can be adjusted to regulate the chip removal, the chip removal is often from the side.

On surfaces worked with electric planes, traces of the use of the knife can usually be seen as fine lines across the planing direction. They are known as plane cuts.

Hand planing machine from 1958 (USSR, 400 watts) with external rotor - asynchronous motor, three-phase current connection, the planer knives are directly attached to the external rotor

history

The plane came around 1200 BC. Chr. On. The oldest surviving pieces date from the Roman Empire . The layer or gouging planer is one of the oldest types of planes. Even if many types of planes were mostly replaced by machines in everyday life, the correct handling of them is still part of training in the carpenter's trade today.

Types of planing tools

The different planes can be classified according to their purpose:

Flat surfaces

They are listed in the order in which they are used when processing a rough-sawn surface:

- Roughing plane - is used by removing thick chips to level the saw cut and to produce the approximate workpiece thickness ( roughing down ). The plane iron that protrudes far has a rounded (segment-arc-shaped) cutting edge.

- Finishing planer - used for the first smoothing and finishing of the still undulating surface (after roughing).

- Double plane - like finishing plane, but with a double iron. The double iron forms an edge just behind the cutting edge on which the chip is broken, so that a smoother surface is achieved.

- Raubank - quite long planer, is used primarily for the production of larger flat surfaces and straight edges as well as for joining (preparing the wood for gluing) larger workpieces or veneers.

- Smoothing planes and Reform smoothing planes - are used to clean solid and veneered wooden surfaces, work finer than the double planer. The cutting angle is slightly larger at 48 to 50 °.

Curved surfaces

- Ship planes - have a concave or convex curved plane sole or, in the metal version, a flexible steel sole, which can be adjusted both convex and concave by means of an adjusting screw. This allows you to plan curves.

- Tail plane - also known as a "scraper" or "Schinder" - has a very short sole that can be flat, convex or concave. The iron is adapted to the shape of the sole. The tail plane is pulled by means of two handles on the side and is used to shape smaller workpieces and to break edges. The tail plane is similar in appearance and use to the draft knife .

Constructive forms

-

Edge planer - with this mostly narrow planer, the planer knife extends over the entire width of the planer box so that you can plan into the inside corner of a rebate .

- Ledge plane - with a simple iron for bumping and working out rabbets.

- Double rabbet plane - rabbet plane with double iron for cleaning and overcasting seams.

- Heeled cornice planer or corner cornice planer - with a short or completely without planer box in front of the knife for planing to the end of recessed or mitered rebates.

- Rebate planer - with side and depth stop and pre-cutter for the exact creation of rebates.

- Durrant plane - has an angle of 78 ° between the sole of the plane and the side surface, which enables the planing of ridged springs. To prevent the end grain from tearing, it also has a pre-cutter.

- Ground plane - has a narrow blade that protrudes far above the sole of the plane. This makes it possible to plan the bottom of a groove , especially of flutes.

- Grooving Plane - have a narrow, straight blade with the same, stepped sole, often with adjustable depth and side stops, for the exact creation of grooves .

Decorative forms

- Profile planes , also known as facon planes - have a profiled plane sole with a corresponding blade. This can be used to create profiles. As a rule, a special plane is necessary for each type of profile. Profiles are today, not least, mostly for reasons of operational speeds mechanically milled .

- Chamfer Planer - for creating a bevel

special cases

- One-hand planes or pocket planes - are small planes that are guided with one hand.

- Fidibushobel - for making Fidibuses . Here the chip produced is the product and not waste. Usually these planes are attached to the table. The wood is guided by hand.

- End grain planing or Vergatthobel - are mostly made of metal and are used for planing the wood brain. In contrast to the normal planing process, which takes place parallel to the grain of the wood, the end grain planer works across the grain . This requires a very stable plane with the smallest possible cutting angle.

- Core box planer - has a right-angled planer base, for making semicircular gutters (such as rain gutters).

- Surform planes - are similar in structure to a plane, but have a rasp sheet for surface processing .

- Toothed planes - with their very large cutting angle of around 80 °, have a scraping rather than cutting effect. Fine grooves are milled into the plane iron, which roughen the surface to be processed. This is used to roughen wooden surfaces for subsequent gluing.

- Scraper plane - even Furnierschabhobel, like the Spokeshave a short plane body with two side handles, in which a scraper is clamped. It can be used to pull off large areas and remove glue traces and scraps of paper after veneering .

Assortment of finger planes from a violin maker , usable with one hand

saying

The saying “Wherever planing takes place, there are shavings” expresses that certain disadvantages have to be accepted for something that is good and useful in itself.

See also

literature

- Josef M. Greber: The history of the plane: from the Stone Age to the emergence of the wooden tool factories in the 19th century. VSSM, Zurich 1956. (Edition "libri rari". Schäfer, Hannover 1992)

- Kurt Günter Heid: woodworker planer. Planes of various woodworking professions. BOD Verlag, Norderstedt 2019, ISBN 978-3-7481-7432-5

Web links

Individual evidence

- ^ A b Authors' community: Book of tables for wood occupations Bildungsverlag EINS, Troisdorf 2002, ISBN 3-441-92350-2 , pp. 148-149.

- ↑ Günther Heine: The carpenter's and turner's tool. Verlag Th.Schäfer, Hannover 1990, ISBN 3-88746-228-9 , p. 119. (online at books.google.de )

- ^ Kurt Günter Heid: Holzwerker Hobel , Books on Demand, p. 627, ISBN 9783748174325

- ↑ Wolfgang Nutsch and others: expertise for carpenters (12th edition), published by Europa-Lehrmittel, Wuppertal 1980, page 244, ISBN 3-8085-4011-7

- ^ Duden, The big book of quotations and idioms , Mannheim 2002, ISBN 978-3-411-71801-6